5052 H32 Mirror Finish Aluminum Sheet

In today’s market, materials that combine strength, durability, and elegant appearances are always in high demand. One such material delivering immense value to industries ranging from automotive to architecture is the 5052 H32 Mirror Finish Aluminum Sheet. Renowned for its remarkable corrosion resistance and high strength-to-weight ratio, when enhanced with a mirror finish, it serves not just as a structural component but also as a gleaming surface that elevates the aesthetic quality of any product.

What is 5052 H32 Mirror Finish Aluminum Sheet?

Alloy and Temper Explanation

5052 aluminum alloy primarily contains magnesium (Mg) as its major alloying element (approximately 2.5%), which grants it outstanding corrosion resistance particularly against seawater and industrial chemicals. Its composition is non-heat-treatable and is strengthened mostly by cold working.

The temper H32 designation in the aluminum industry describes an alloy that has undergone intermediate annealing (partial strain hardening) resulting in a certain balance of tensile strength and ductility. Specifically for 5052 alloy, H32 temper indicates:

- The metal is strain-hardened and stabilized.

- It possesses higher strength compared to soft tempers while maintaining moderate ductility.

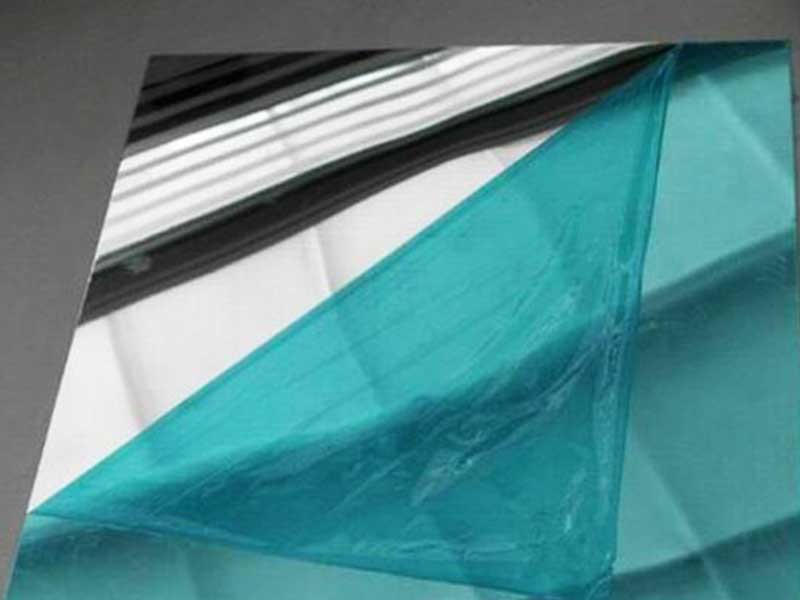

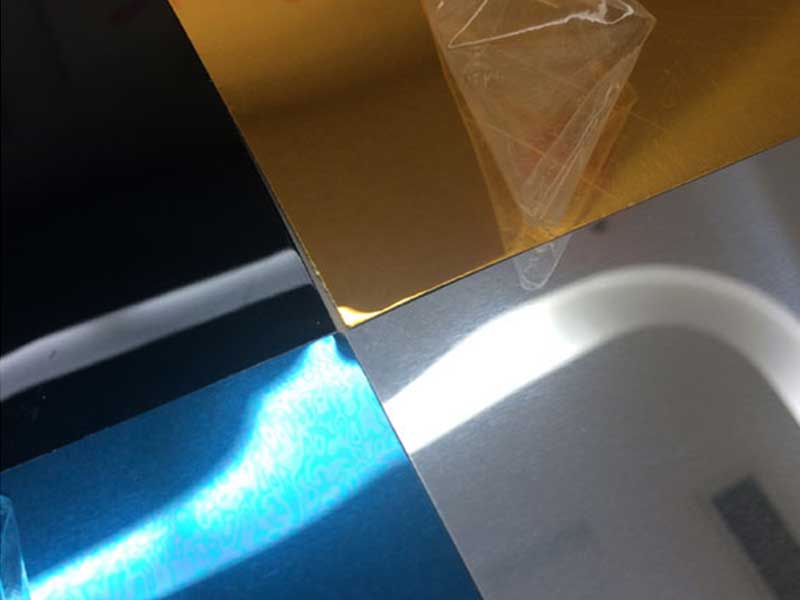

Mirror finish in this context means the sheet surface undergoes mechanical polishing followed by electro-polishing or buffing so that it achieves a reflective, mirror-like surface with brightness and smoothness not possible with standard mill finishes.

Chemical Properties of 5052 Alloy Aluminum Sheet

Below is an overview of the nominal chemical composition as per ASTM B209 and ISO 6361 standards:

| Element | Percentage (%) |

|---|---|

| Magnesium (Mg) | 2.2 – 2.8 |

| Chromium (Cr) | 0.15 – 0.35 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.25 |

| Copper (Cu) | ≤ 0.1 |

| Manganese (Mn) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.1 |

| Aluminum (Al) | Remainder (Balance) |

This precise blend lends 5052 alloy its durability and exemplary resistance to attacks from marine environments, salt spray, and oxidation.

Technical Parameters

| Parameter | Typical Value (H32) |

|---|---|

| Tensile Strength | 210 – 230 MPa |

| Yield Strength | 130 – 160 MPa |

| Elongation at Break | 7 – 12% |

| Density | 2.68 g/cm³ |

| Thermal Conductivity | ~138 W/m·K |

| Electrical Conductivity | 38 – 42 % IACS |

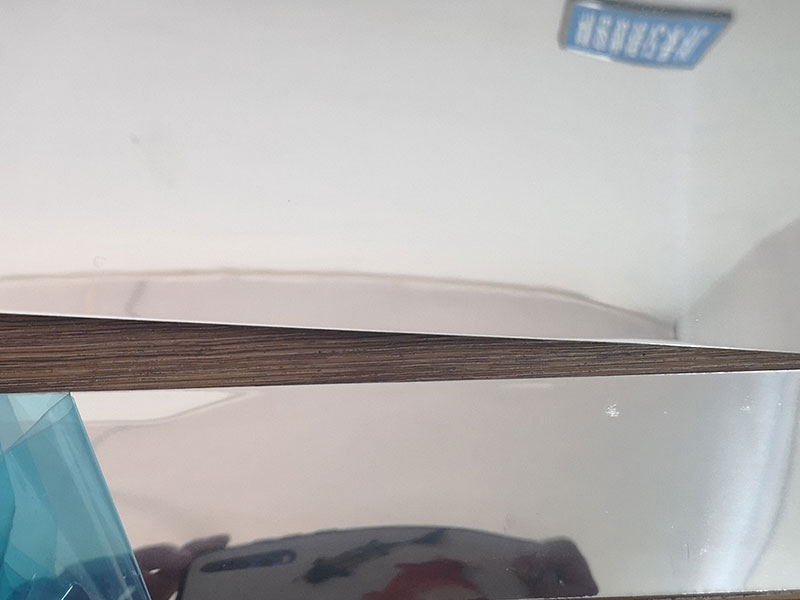

| Thickness Range (common) | 0.3 mm to 6 mm |

| Width | Typically up to 2000 mm |

| Temper | H32 – Work-hardened & Stabilized Moderate Hardness |

These parameters indicate a material delivering good hardness without sacrificing formability, making the mirror 5052 H32 suitable for shapes and bends while retaining its attractive, gleaming surface integrity.

Implementation and International Standards

The 5052 H32 Mirror Finish Aluminum Sheet typically complies with internationally recognized standards including:

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate.

- ISO 6361: Specifications for wrought aluminum sheets.

- EN 573-3 & EN 515: European standard defining Chemical composition and properties.

- Electro-polishing and mirror finish procedures adhere to ISO 3170 (Surface Finish Specifications and Measurements).

Certification ensures the sheet meets precise quality criteria for thickness tolerance, mechanical properties, surface finish, and chemical composition crucial for rigorous industrial use.

Outstanding Functions and Applications

Versatile Corrosion Resistance for Harsh Environments

The 5052 alloy’s high magnesium and chromium content translate to superb rust and corrosion resistance. Coupled with mirror finish, this sheet shines not only visually but also protects components against oxidation and degradation caused by chemicals or saltwater. Hence, it is vastly popular in marine equipment, storage tanks, chemical containers, and architectural facades exposed to severe weather conditions without losing brilliance.

Structural Strength Balanced with Formability for Design Excellence

Unlike softer aluminum sheets, the H32 temper gives you the advantage of enhanced strength (up to nearly twice that of pure aluminum) while maintaining workability for bending, shaping, or riveting. The mirror finish adds value in applications demanding flawless surface qualities such as elevators, decorative panels, and luggage manufacturing.

Heat Dissipation and Lightweight Instantly Usable Material

With low density and excellent thermal conductivity, 5052 mirrors are preferred in electronic casings, automotive trim, and cooling panels, where heat management is as critical as presentation. Its light weight reduces the overall assembly weight promoting fuel efficiency or ease of handling.

Why Choose 5052 H32 Mirror Finish Aluminum Sheet over Other Metals?

- Superior Corrosion Resistance: Even after extensive exposure, the mirror folio retains lustrous appearance and functional excellence.

- Strong but Formable: Perfect for tailored manufacturing processes.

- Ease of Maintenance: The mirror surface prevents depositing dirt and facilitates cleaning.

- Cost-Effective: Offers longevity that outweighs initial costs compared to stainless steel or painted options, with an added aesthetic bonus.

- Environmentally Friendly: Easily recyclable without performance compromising.

https://www.aluminumplate.net/a/5052-h32-mirror-finish-aluminum-sheet.html