Alloy 3003 3004 5052 5083 Grade Aluminium Mirror Finish Sheets

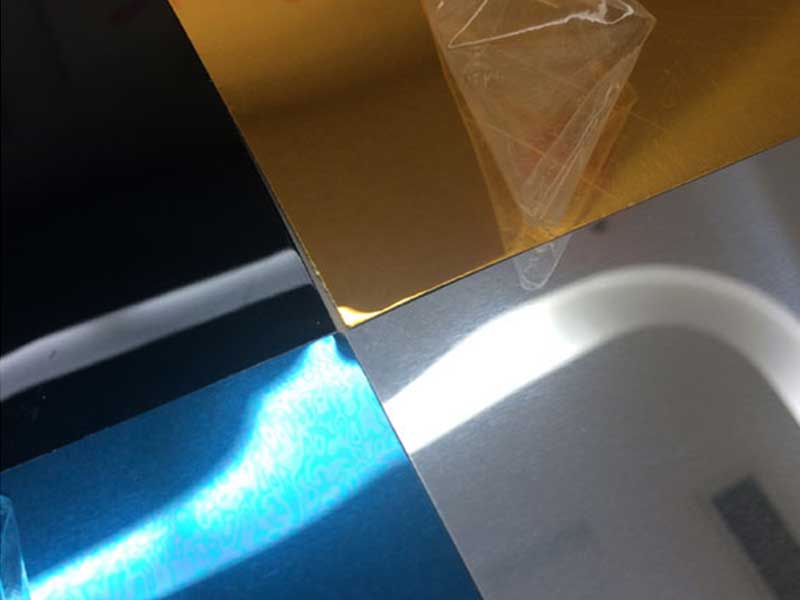

When we think of aluminum sheets, the first image often is of plain, matte surfaces used in construction or manufacturing. But beneath that surface lies a world of incredible variety, especially when these sheets are given a mirror finish — a luscious, reflective sheen that dazzles both visually and functionally. Today, let's explore four prominent aluminum alloys — 3003, 3004, 5052, and 5083 — and the unique story they tell when transformed into mirror finish sheets.

Why Mirror Finish Sheets?

Mirror finishing aluminum sheets isn’t just about adding shine; it transforms the material’s character. The process involves polishing the surface to a smoothness that reflects light like glass, turning utilitarian metal into an object of elegance and precision. This finish is not only aesthetic — it adds corrosion resistance, reduces friction, and helps in applications demanding clean, hygienic surfaces.

Now, how do different alloys react to this treatment, and why choose one over another? That's where our u

Alloy 3003: The Multitasker with a Polished Persona

Alloy 3003, known as one of the most commonly used aluminum alloys, is almost like the reliable “everyman” in the aluminum world. Alloyed mainly with manganese, it's renowned for good corrosion resistance, excellent workability, and moderate strength.

When 3003 is given a mirror finish, it transcends its standard industrial image. The smooth, brilliant surface makes it ideal for decorative applications like retail interiors, kitchen equipment, and even artistic installations. Imagine a mirrored aluminum backsplash that sparks reflections in your kitchen but remains lightweight and durable.

Despite its softer nature compared to some alloys, alloy 3003’s ability to achieve a flawless mirror finish without cracking or losing its corrosion resistance is what sets it apart.

Alloy 3004: The Upgraded Performer with Enhanced Strength

Alloy 3004 is often seen as a strengthened sibling of 3003, offering somewhat higher tensile strength due to its added manganese and magnesium content. This makes it a superior choice when a mirror finish is desired but when extra durability is required — think of environments frequently exposed to wear and tear.

3004’s mirror finish brings about a striking blend of aesthetic and industrial qualities, suited to ceilings, elevator panels, as well as kitchen equipment that demands both durability and sheen.

The subtle difference in alloy composition compared to 3003 means it can withstand mechanical deformation during the finishing process a bit better, ensuring a long-lasting lustrous appearance.

Alloy 5052: The Coastal Champion Reflecting Brilliance

Moving into the realm of marine-grade tubing, alloy 5052 shows its mettle nearer salty waters and aggressive environments. With excellent resistance to chloride corrosion, it's a favorite in boatbuilding, fuel tanks, and pipelines.

By applying a mirror finish to 5052 sheets, engineers infuse charm into function. Imagine the gleaming hull trim or bright exterior panels on yachts, reflecting sunlight while beating corrosion.

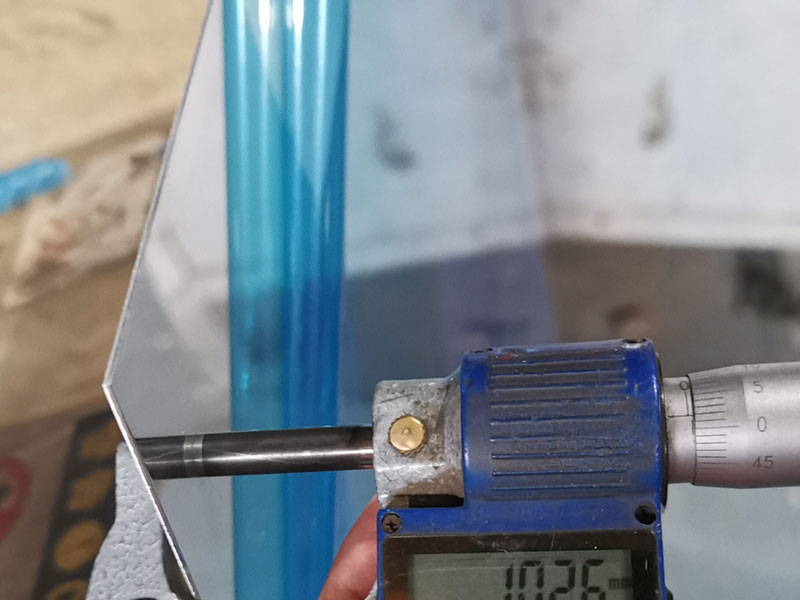

Its magnesium content (2.5%) adds both strength and resistance, making finishing somewhat trickier, but perfected manufacturing controls achieve a mirror mirror surface that dazzles even the harsh sea breeze.

Alloy 5083: The Heavy Duty Hero in a Lustrous Coat

Among these four alloys, 5083 is the heavyweight champion. With superior strength and exceptional corrosion resistance — especially in marine and hostile industrial environments — 5083 is the go-to alloy where endurance is non-negotiable.

When industrial strength intersects artistry, the polished 5083 sheets make a statement. Think aerospace interior trims, naval architectural features, or heavy machinery panels where look meets longevity.

Achieving a mirror finish on 5083 necessitates meticulous polishing due to its alloying elements like magnesium and trace chromium. The end result, however, is rewarding: a finish that reflects brilliance without compromising ruggedness.

Final Thoughts: Choosing the Right Alloy as per Your Mirror Finish Needs

If you want ease of forming combined with an appealing finish — 3003 shines brightly.

Need a bit more strength and reliability under frequent use? Pick 3004.

Require corrosion resistance in coastal or chemical environments yet desire polished beauty? The 5052 alloy is your ally.

And if your use demands bulletproof resistance and top-tier strength alongside a mirror gloss? Opt for 5083.

Mirror-finished aluminum sheets present a fusion of nature’s reflective magic and human craftsmanship. When coupled with the inherent characteristics of alloys 3003, 3004, 5052, and 5083, they redefine what aluminum can be: not just a metal, but a versatile medium for artistry and performance.

In a world increasingly focused on aesthetics meeting functionality, the mirror finish aluminum sheets in these grades waste no opportunity to glitter where it counts — be it mid-century kitchens, luxury yachts, or industrial marvels.

https://www.aluminumplate.net/a/alloy-3003-3004-5052-5083-grade-aluminium-mirror-finish-sheets.html