7075 Mirror Finish Aluminum Sheet Plate

Let’s face it — aluminum is everywhere, but not all aluminum is built the same. Amongst the varied families of aluminum alloys, 7075 aluminum is the rockstar for anyone who needs serious strength without sacrificing too much weight. Now, throw a mirror finish into the mix, and you end up with a material that’s not just strong but also catches the eye in the most literal sense. So, what’s the deal with the 7075 mirror finish aluminum sheet plate, and why should you care? Let’s peel back the layers.

7075 Aluminum Alloy – Strong Enough to Impress

At its core, 7075 aluminum is an alloy primarily made from zinc; that’s what gives it serious muscle. It’s widely prized for its exceptionally high strength-to-weight ratio—think aircraft wing parts and motorcycle components that need to withstand some serious predicaments but keep the load manageable. Besides zinc, the all-star formula includes magnesium, copper, and chromium that all blend to create a heavyweight fighter in the aluminum category.

7075 aluminum alloy is a popular choice for mirror finish applications due to its high strength and excellent corrosion resistance, making it ideal for demanding environments. However, achieving a truly specular mirror finish on 7075 presents unique challenges. Its inherent hardness necessitates more aggressive polishing techniques, increasing the risk of subsurface damage or introducing micro-scratches that will compromise the final reflective quality. We've found that multi-stage polishing using progressively finer abrasives, coupled with meticulous control of process parameters like pressure and speed, is critical. Furthermore, the choice of polishing compound is crucial – certain compounds can leave residue that obscures the mirror finish, requiring additional cleaning steps and potentially affecting longevity. Careful attention to surface preparation before polishing is also to achieving a consistent, high-quality result.

A significant factor affecting the final product is the inherent consistency of the raw material. Minor variations in the initial sheet's metallurgical structure can impact the final polish, leading to uneven reflectivity or areas that are prone to tarnishing more quickly. We've seen instances where seemingly minor variations in the annealing process can drastically alter the ease with which a mirror finish can be achieved. Consequently, strict quality control on the incoming 7075 sheet is paramount. This includes rigorous inspection for surface imperfections and careful measurement of material properties before even beginning the polishing process. Ultimately, producing a high-quality 7075 mirror finish sheet is a delicate

- High tensile strength: Around 74,000 psi, making it stronger than many steels.

- Good fatigue resistance: Which means it holds up well when subjected to repetitive stress.

- Moderate corrosion resistance: Not the best in the aluminum realm, but definitely manageable with the right coatings or anodizing.

This natural fortitude lines up perfectly with applications where durability and weight efficiency are paramount.

Mirror Finish – More Than Just Looking Good

Now l

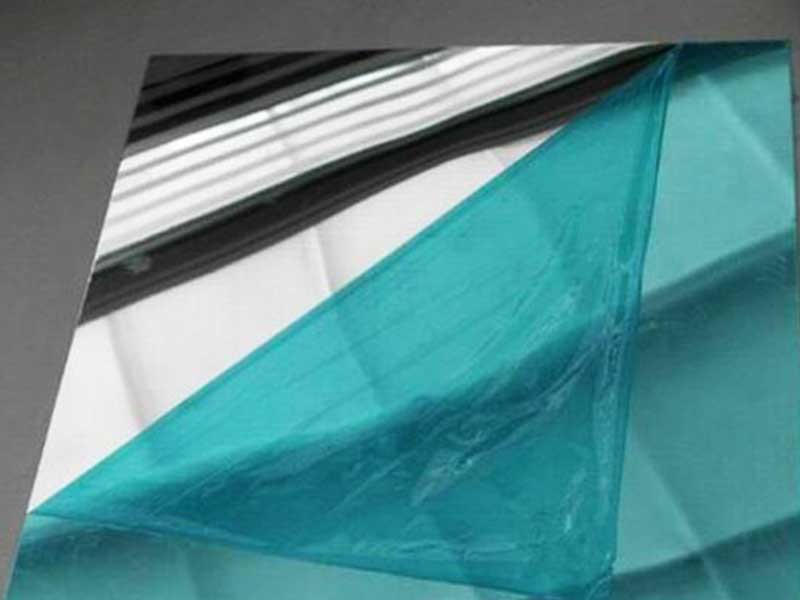

Achieving a mirror finish on 7075 aluminum sheet is no simple polish—it's a blend of expert grinding, buffing, and sometimes chemical honing that strips tiny surface imperfections until you get that flawless reflective sheen.

Here’s what the mirror finish brings to the table:

- Reduced friction: The polish smooths out the microscopic roughness, which means, less resistance when parts have to move or slide past each other.

- Corrosion resistance bump: Though 7075’s natural resistance isn’t legendary, a mirror-finished surface offers plants, machinery, and automotive parts an extra customizable protective platform to ward off corrosion.

- Aesthetics for precision industry parts: Think medical devices, aerospace components inside jet engines, or consumer electronics that require not just function but sleek elegance.

- Hygiene value: In food and pharmaceutical industries, smooth mirror finish surfaces prevent bacteria buildup because there are fewer tiny crevices to harbor contaminants.

What Kind of Applications Are We Talking About?

7075 mirror finish aluminum sheet plates shine particularly bright in industries where their combined strength and shiny smoothness push them from a good choice to a smart one:

- Aerospace Components: High-performance aircraft parts like fuselage sections, leading edges, or structural supports often demand top-notch strength; having a mirror finish on certain elements can enhance airflow efficiency and surface inspection.

- Military Gear: From durable firearm parts to military-grade drones, these aluminum sheets complement ruggedness with a stealth clean-sheet polish.

- High-end Sporting Goods: Bicycles, rock climbing gear, or even premium hunting rifles—strength and lightweight nature is prized, and that glimmer-on-shiny protective bond sweetens the deal.

- Motorsports & Automotive: Racecar body panels or heat shields capitalize on the lightweight property, while the mirror polish reduces drag and assists in thermal regulation.

- Electronics and Precision Devices: Housings or chassis that must ride fast in cleanroom environments benefit from both structural integrity and residue-resistant tall shine.

Handling and Care Tips (A Quick Heads-Up)

Even though 7075 is beefy by aluminum standards, those gorgeous mirror finishes need a bit of TLC:

- Avoid abrasive cleaners—they tarnish the shine faster than you’d like.

- Consider clear coatings to lock in both corrosion resistance and polish time.

- When machining mirror finish sheets, keep tools razor-sharp to prevent scratching superficial luster.

Wrapping It Up: The Mirror’s Paradox

The 7075 mirror finish aluminum sheet plate embodies a fine paradox: it’s robust enough to take heavy punishment on the front line, yet refined enough to hold a crystal-clear shine that can double up in environments where cleanliness and precision are as vital as strength itself.

Whether you’re an engineer cooking up a design for aerospace excellence or a craftsman seeking tough yet polished material, this alloy-and-sheen combo offers a neat blend of function and form. It proves aluminum selection isn’t just about what the metal can take—it’s about what it can show.

If you’re thinking of mixing top-grade aluminum’s raw power with visual and practical pizzazz—this shiny workplace champion just might be the answer.

https://www.aluminumplate.net/a/7075-mirror-finish-aluminum-sheet-plate.html