3003 5052 mirror finish aluminum alloy polished aluminium sheet

When it comes to aluminum sheets, the alloy composition plays an astonishingly vital role in shaping characteristics that determine usability and performance. Among these, the 3003 and 5052 mirror finish aluminum alloy polished sheets stand out, not just for their aesthetic appeal, but also for their unparalleled functionalities across diverse applications.

Aesthetic Allure Meets Functional Make-Up

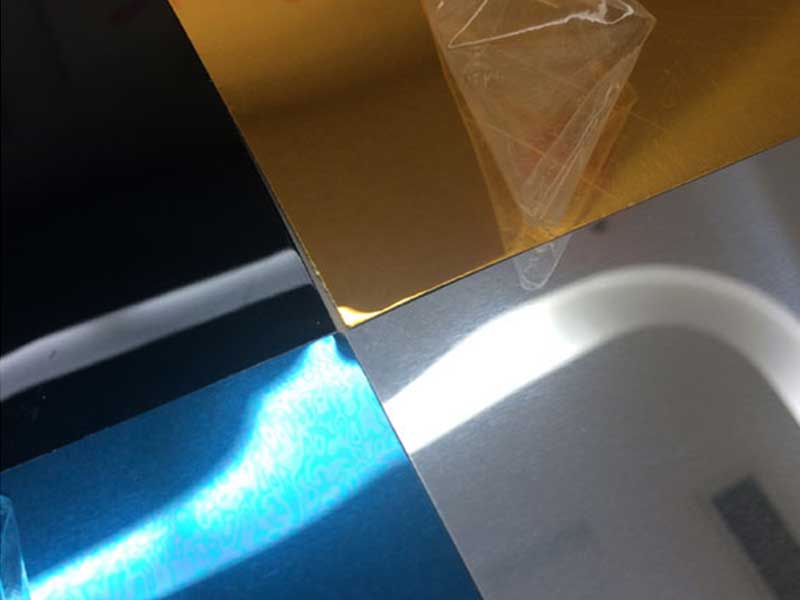

The distinctive mirror finish achieved on aluminum sheets, particularly 3003 and 5052 alloys, isn’t merely for visual appeal; it serves multiple purposes. The highly polished surface reflects light, making it ideal for high-end applications where aesthetics—notably in architectural design, signage, and automotive interiors—are paramount. The sleek, polished look evokes a sense of luxury while doubling as a strategic element to combat tarnishing and corrosion.

Material Properties that Matter

3003 Alloy:

3003 aluminum alloy is renowned for its excellent corrosion resistance and moderate strength. With its superior working ability and ease of forming, 3003 is a preferred choice for many industries. When polished, it showcases a brilliant reflective surface, suitable for decorative applications. The alloy features a good strength-to-weight ratio, leading to lower material costs without compromising structural integrity.

5052 Alloy:

On the other hand, the 5052 alloy elevates performance through enhanced weldability and resilience. Known for its manganese content, 5052 portrays remarkable resistance to marine environments, making it an exceptional candidate for coastal applications such as boating and ocean-based equipment. The mirror finish on 5052 sheets not only fortifies them with an additional protective layer but also enhances their elegance for aesthetic projects.

Functions Beyond Reflection

The use of polished aluminum sheets of both alloys stretches far beyond the boundaries of beauty.

-

Architectural Applications: Both alloys are extensively used for facade designs and interior finishes due to their reflective surface that intensifies natural lighting and reduces energy costs. Architects admire their lightweight structure, making the design easier to work with while maintaining optimal durability.

-

Transport Industry: Whether in automotive manufacturing or aviation, 3003 and 5052 polished sheets bring forth the dual advantage of reducing weight along with amplified resistance. The lightweight nature allows for maximized fuel efficiency while appointing vehicles with a clean, polished finish.

-

Food and Beverage Industry: The corrosion resistance properties of these alloys are particularly valued in hygiene-focused sectors. Food processing equipment utilizing polished aluminum sheeting ensures that surfaces are easy to clean and maintain, reducing contamination risks.

-

Art and Design: Reflective surfaces create depth and dimension in artistic installations. Artists leverage the brilliance of mirror finishing to engage viewers, while designers harness the polished aluminum sheets for eye-catching décor elements striking a balance between form and function.

-

Signage: The shiny exterior affords a captivating element to signs and banners. The ability to reflect light enhances visibility, while the great durability complements outdoor resilience.

https://www.aluminumplate.net/a/3003-5052-mirror-finish-aluminum-alloy-polished-aluminium-sheet.html