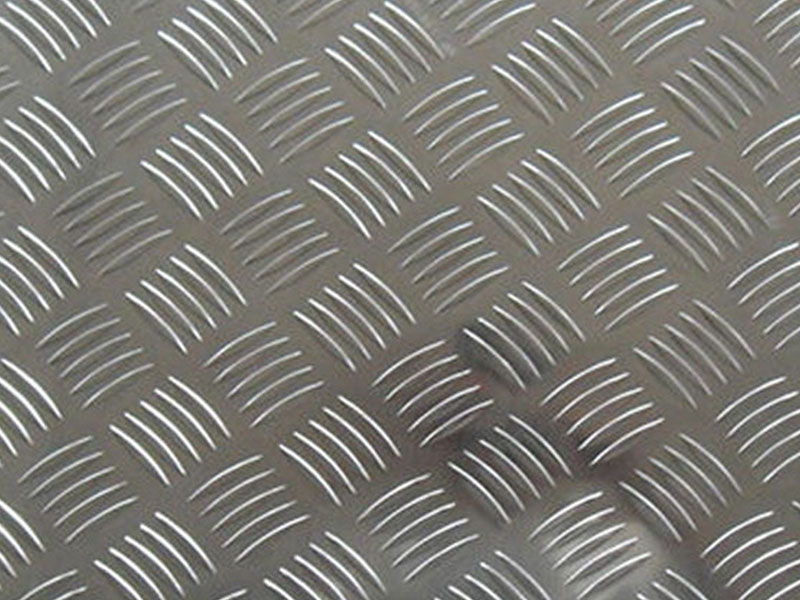

Embossed aluminum sheet mill finish EN-AW 2024

the Versatility and Functionality of Embossed Aluminum Sheet Mill Finish EN-AW 2024

Aluminum continues to be a game-changer across a multitude of industries due to its lightweight properties, exceptional strength, and resistance to corrosion. Among the various aluminum alloys available, the EN-AW 2024 embossed aluminum sheet in a mill finish stands out not only for its structural integrity but also for its aesthetic appeal.

the Alloy: EN-AW 2024

Before we jump into its applications, it's crucial to understand what makes EN-AW 2024 so robust. This aluminum fusing an exceptional combination of high strength, excellent fatigue resistance, and superior mechanical properties primarily results from its composition. With copper as its primary alloying element (up to 4.9%), 2024 is renowned for its remarkable resilience and durability. Stable electrical conductivity and formability allow for diverse uses across different sectors.

Furthermore, the embossed texture adds unique functionality, imparting surface-wear resistance, slip resistance, and aesthetic contrast. The vast majority ofENDSAW 2024 embossed aluminum sheets encountered are fabricated using a mill finish, allowing industries to strike a balance between visual appeal and practicality.

Technical Specs at a Glance

- Thickness: 0.5 mm - 10 mm (Varies based on customer specification)

- Width: Commonly available widths range from 1,000 mm to 2,600 mm

- Length: Typically customized

- Density: Approximately 2.78g/cm³

- Yield strength: Around 350 MPa

- Ultimate tensile strength: Ranges from 470 to 550 MPa

These specifications underscore that embossed aluminum sheets of EN-AW 2024 are lightweight while providing rigidity far superior to numerous other materials within the same context.

Diverse Applications of Embossed Aluminum Sheet EN-AW 2024

-

Aerospace Industry: One of the most pivotal utilizations of EN-AW 2024 embossed aluminum sheets lies within the aerospace sector. Known for its lightweight and strong characteristics coupled with its resistance to fatigue, it is well-suited for aircraft and spacecraft components where reducing weight without compromising strength is critical.

-

Automotive Industry: With continuous advancements in automotive design focusing on fuel efficiency, the use of materials like 2024 embossed aluminum helps streamline vehicle frames and structural components. The alloy delivers not just stability and strength but also an attractive finish when treated with proper coatings.

-

Commercial Building Facades: In the construction industry, the porous nature of the embossed surface is not solely an aesthetic preference; it also helps in reflecting residual heat and preventing oversaturation. Applications in wall panels, ceiling systems, and roofing culminate in both beauty and energy efficiency.

-

Marine Applications: Awareness of corrosion resistance makes 2024 embossed aluminum sheet a valued resource in marine structures and vessels. While primarily employed in structural components, it visibly routes moisture with its textured surfaces, increasing lifespan and functionality.

-

Consumer Electronics: In weighing ergonomics with reliability, the embossed aluminum sheet brings a fashionable utility in devices like computer cases, laptops, and smart appliances. It aligns with varying design aesthetics while concentrating on thermal dispersal thanks to the textured surface.

https://www.aluminumplate.net/a/embossed-aluminum-sheet-mill-finish-en-aw-2024.html