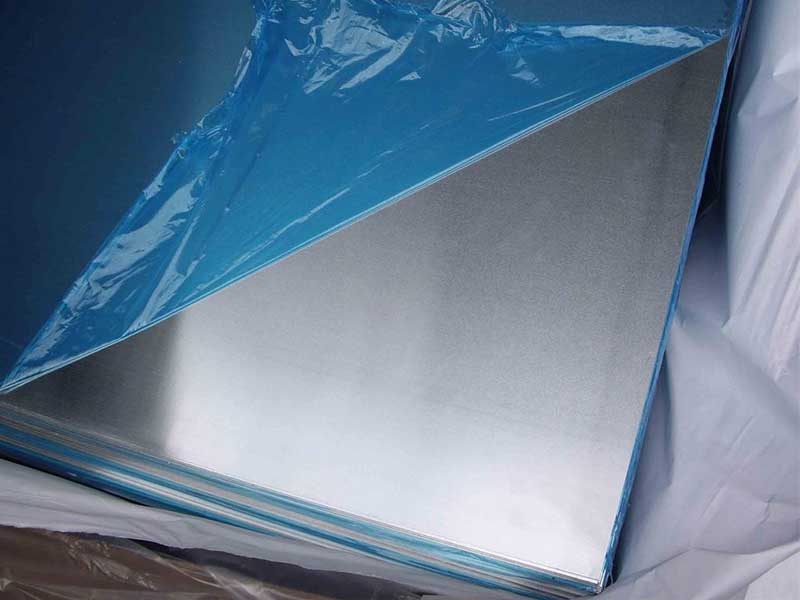

Ctp plate base aluminium coil

In the ever-evolving world of print technology, every component of the production process plays a significant role in determining output quality, operational efficiency, and cost-effectiveness. One such unsung hero is the CTP (Computer-to-Plate) plate base aluminium coil. While ink, engage, and presses typically bask in the limelight, it’s essential to shine a spotlight on what truly underpins the printing process—the materials used in creating those all-important plates.

CTP and Its Importance

CTP technology is at the forefront of modern printing techniques, offering a digital alternative to traditional platemaking processes. This revolution in prepress workflows has drastically improved quality, speed, and productivity while reducing material waste and operational risks. A core component of CTP technology is the base upon which these plates are fabricated; enter the aluminium coil.

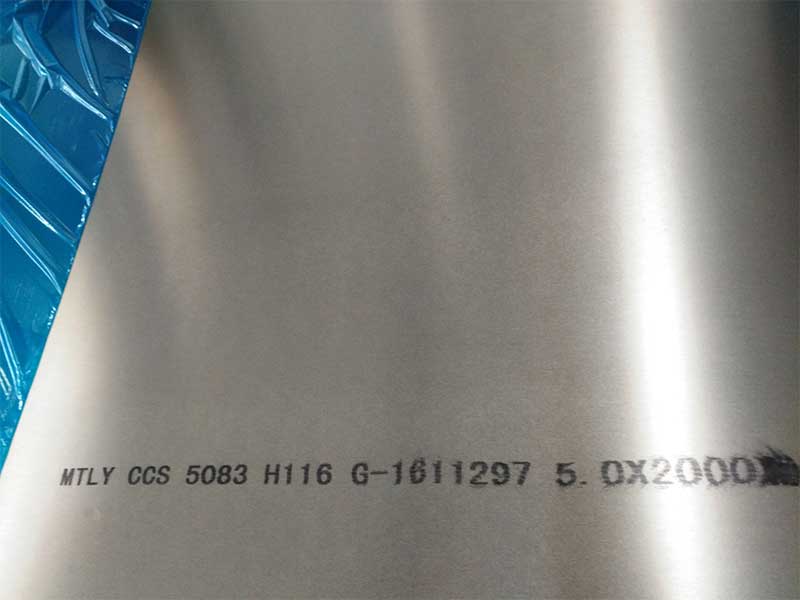

The quality of our aluminium CTP plate hinges entirely on the base coil, and it's a source of constant fascination and occasional frustration. We're not just dealing with any aluminium; the subtle variations in alloy composition, grain size, and surface finish profoundly impact the final product's performance. A slightly higher magnesium content might improve imaging sharpness, but at the cost of increased susceptibility to scratching. Similarly, the temper – the degree of work hardening – needs to be precisely controlled to ensure the right balance between strength and flexibility for optimal plate processing and printing. It's a delicate dance between material science and manufacturing realities, constantly pushing us to optimize our processes to minimize waste and maximize the potential of each coil.

Beyond the technical specifications, I've learned that the supplier relationships are critical. Building trust and open communication with our coil suppliers is paramount. We need to understand their manufacturing processes, their quality control measures, and even the nuances of their raw material sourcing. A seemingly small change in their smelting process, for example, can ripple through our production line, requiring adjustments to our own procedures. It's a collaborative effort; we're not just buying a product, we're partnering to produce the best possible aluminium CTP plate, and that shared makes all the difference in ensuring a consistent, high-quality output.

Why Aluminium?

Aluminium is the preferred choice for CTP plates due to its remarkable properties. It’s lightweight yet incredibly strong, corrosion-resistant, and, importantly, provides precision and uniformity throughout the printing process. When a CTP plate is manufactured on an aluminium coil, it results in precise imaging capabilities, ensuring optimal reproduction fidelity and vibrant color accuracy.

Beyond its performance benefits, aluminium demonstrates exceptional plate run-length durability. The ability of aluminium CTP plates to endure both sheetfed and web printing environments helps printers maximize uptime, reducing the need for frequent replacements or maintenance interruptions.

The Hardware Aspect: From Coil to Plate

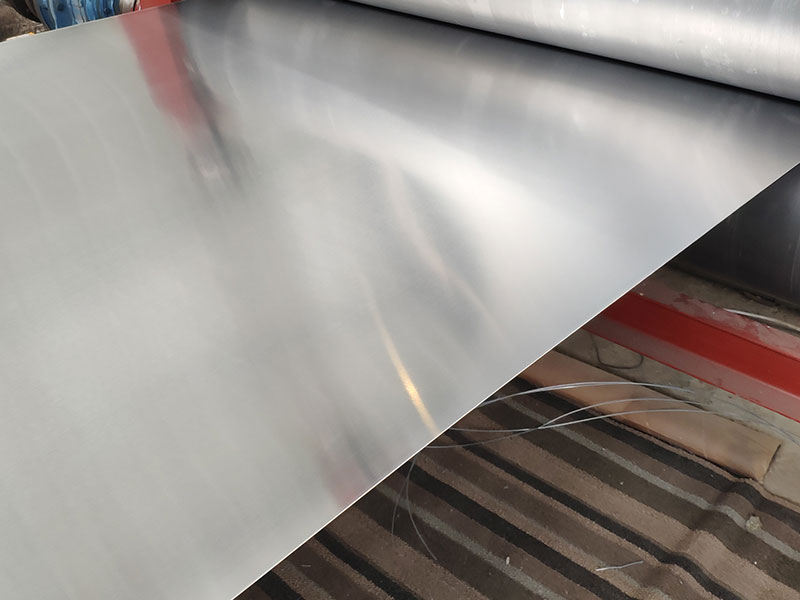

The journey from a CTP plate base aluminium coil to the finished printed material is intricate and processes highly engineered to ensure uncompromising quality. Initially, the aluminium coil is carefully prepared through processes such as :

-

Cold Rolling: Transforming thick plates into thinner gauges for enhanced toughness and improved thermal conductivity.

-

Chemical Treatment: A crucial step to ensure the best surface properties—optimizing for both the lithographic process and quality control.

-

Colors and Coatings: Special coatings are further applied for image reproduction, ensuring the plate attracts ink uniformly while repelling water during the printing process.

The complexities involved in handling these actions emphasize the importance of utilizing a high-quality aluminium coil, as it can bring about seamless conversion into functional printing plates.

Sustainability Matters

As the printing industry faces increasing pressure to adopt sustainable practices, it’s worth acknowledging that alu-minium coils are fully recyclable. Once plates have significantly contributed to numerous impeccable prints, those same aluminium materials can be repurposed, minimizing waste and promoting resourcefulness. Invest in high-quality CTP plate base aluminium coils helps create an environment where primary materials are continuously cycled without straining natural resource landscapes.

The Future of Printing with CTP Technology

As we look towards the future of print technology, CTP base aluminium coils stand ready to continue driving the industry forward. Ongoing research and developments assure that future aluminium coils will be even more advanced, supported by improvements in manufacturing technology that scream rapidity, quality, and efficiency. Coupled with the already existing role of these components in improving prepress efficiency, they provide quite the visible marker for successful print campaigns—a fusion of innovation and reliability.

In conclusion, emphasizing the often-overlooked aspect of the CTP plate production process is vital. The base aluminium coils might not be as glamorous as the ink or the paper at face value, but without these, the arteries of the print industry would undoubtedly ache. As users of this technology—from large commercial printers to specialized units—it’s our duty to appreciate the functionality, efficiency, and sustainability that CTP plate base aluminium coils impart to ensure the decorations of the popular marvel of print continue to dazzle and inspire.

By recognizing the unsung hero that is the CTP plate base aluminium coil, you're equipped not just to bail a Christamas Spirit for your print campaigns but now also injected opinions about how production harmony breaks away from environmental constraints—all undertaken for material perfection on the genre canvases we thrive on!

https://www.aluminumplate.net/a/ctp-plate-base-aluminium-coil.html