Gold Color Coated Aluminum Plate Sheet

Technical Features from a Material Science Perspective

1. Coating Innovation:

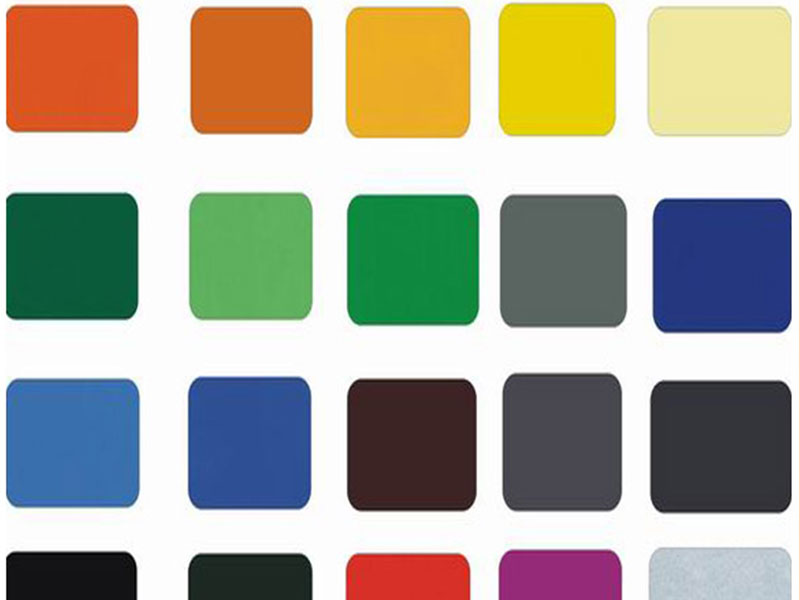

Gold-colored coated aluminum sheet presents unique challenges compared to other coated aluminum products. The vibrant, consistent gold finish is notoriously difficult to achieve and maintain throughout the production process. Slight variations in the coating thickness, alloy composition of the aluminum substrate, or the curing temperature can drastically affect the final hue, leading to unacceptable batch variations. We've found that meticulous control over pre-treatment processes, particularly the cleaning and surface preparation stages, is critical. Even minor inconsistencies in these early steps can translate into blotchy or uneven gold coloration in the final product, resulting in significant waste. Furthermore, achieving a durable, scratch-resistant gold finish that can withstand the rigors of various applications (e.g., architectural cladding, decorative panels) requires specific, often proprietary, coating formulations and careful optimization of the coating line parameters.

Beyond production intricacies, the demand for a "true gold" appearance necessitates ongoing quality control checks. This goes beyond simple visual inspection, involving sophisticated colorimetric analysis to ensure consistent color reproduction across batches and adherence to customer specifications. The subjective nature of "gold" – ranging from pale champagne to deep amber – introduces additional complexity in managing customer expectations. We've found that establishing clear color standards and utilizing digital color management systems is crucial for mitigating discrepancies and maintaining customer satisfaction. Furthermore, the end-use application allows us to tailor the coating's properties – focusing on aspects like corrosion resistance or UV stability – to ensure its longevity and performance

The gold color is usually delivered via PVD—an advanced method where vaporized metal ions deposit onto the aluminum surface under vacuum conditions. This results in a coating that is ultrathin, uniform, and immensely adherent. Unlike paint, PVD coatings demonstrate superior incompressibility and chemical inertness. The transformation of reactive gold ions into a coating culminates in a surface with Mohs hardness often surpassing 3, making it scratch and fade resistant.

2. Thermal Stability:

Controlled thermal management is critical in coated aluminum products. Gold color coated plates withstand direct sunlight and continuous radiant heat without degradation—a significant advantage in outdoor architectural panels or signage.

3. Corrosion Resistance:

The sacrificial aluminum oxide layer naturally forming on aluminum base metal integrates synergistically with the gold coating’s dense, intertwining gold-ion lattice. This acts as a double barrier, vastly enhancing resistance to oxidation, moisture, acids, and pollutants.

4. Mechanical Integrity:

Although coatings add a non-load supporting layer, careful attention to coating thickness—ranging from 0.3 to 1.0 microns—ensures negligible impact on mechanical flexibility or tensile properties. The aluminum substrate retains lightweight characteristics (~2.7 g/cm³) making handling and installation effortless.

https://www.aluminumplate.net/a/gold-color-coated-aluminum-plate-sheet.html