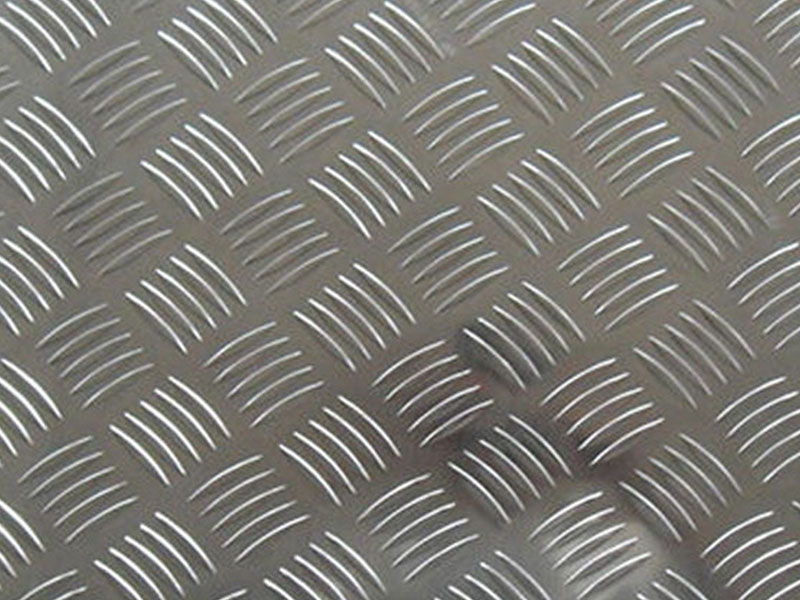

Aluminum tread plate 3003 O H12 H 14 H16

When selecting the ideal aluminum tread plate for industrial or architectural use, temper designations can unlock numerous performance benefits. Aluminum Tread Plate 3003—renowned for its corrosion resistance and excellent machinability—comes in several tempers including O, H12, H14, and H16. Each temper designation uniquely influences the mechanical properties of the tread plate, creating a versatile palette of options suited to varying demands in strength, flexibility, and wear resistance.

Aluminum Alloy 3003

Before diving into temper-specific properties, it's worth noting that 3003 is an aluminum-manganese alloy stabilized by approximately 1.2% manganese content. This elemental mix provides enhanced corrosion resistance and superior workability over pure aluminum (1100 series). As a non-heat treatable alloy, 3003’s strength characteristics predominantly depend on work hardening and mechanical deformation processes.

Decoding the Temper Classifications: O, H12, H14, H16

-

Temper O (Annealed): This temper indicates the softest and most ductile form of aluminum tread plate 3003. An annealed state involves full recrystallization through controlled heating and cooling, stripping away any residual stress and increasing malleability. O temper is especially valuable for applications requiring complex shaping or heavy forming without aluminum fatigue or cracking. However, softer material means it offers lower tensile strength, typically around 13,000 psi.

-

Temper H12 (Work Hardened Stiff Half-Hard): Unlike O temper, H12 features moderate cold working—about 50%—which increases yield strength to roughly 21,000 psi while still maintaining some ductility. The aluminum footprint in the tread plate becomes a bit harder and stiffer against indentation, making it a popular choice where moderate structural strength with some shape retention is critical, such as forklift flooring or vehicle running boards.

-

Temper H14 (Medium Hard): The H14 temper steps up cold working to around 66%, boosting tensile strength closer to 25,000 psi with a decreased elongation percentage. Aluminum tread plates in this state provide sturdier resistance against surface wear and tensile deformation, aligning well with equipment that demands moderate impact tolerance and abrasion resistance.

-

Temper H16 (Stiff-Hard): Nearing the upper cold work limits, H16 involves approximately 75% deformation and aggressive hardening. This increases the tensile strength of 3003 aluminum tread plates to nearly 27,000 psi. Although it sacrifices some ductility, H16 excels in high-load environments where durability under mechanical stress and deformation resistance is paramount. Typical uses include heavy load ramps, walkways in manufacturing plants, or any setting subject to considerable shear and compressive forces.

Why Choose Aluminum Tread Plate 3003 Across Tempers?

The tread patterns themselves, notably diamond, linear, or checker textures, are embossed onto these tempers to provide enhanced anti-slip properties—critical for safety in shoes, equipment, and vehicle platforms. Tread plate metals balance performance with aesthetics by combining functional grip with corrosion resistance unique to aluminum.

Design engineers and procurement managers benefit from knowing these micro-structural distinctions:

- Flexibility Needs: Choose O temper for formed components requiring bending or reshaping.

- Budget and Weight Considerations: Lighter, softer O temper helps minimize energy transfer forces and cuts down cost.

- Strength Demands: H12 through H16 offer varying structural strengths without resorting to heavier or brittle alloy families.

- Environment and Industry Specificity: Corrosive settings like marine applications align with 3003 aluminum’s chromium-free oxidation stability.

Conclusion: Beyond The Surface

Aluminum tread plate 3003—knowingly or unknowingly ordered day-to-day—possesses an inherent complexity governed by temper processing that changes hardness, strength, and flexibility. From O temper’s pliable softness to the rugged stiffness of H16, this spectrum ensures tailored solutions optimized in both industrial manufacturing and creative architectural design. Making the correct choice demands grasping these material differences to achieve maximum longevity and performance in each application.

Embracing the unique metallurgical characteristics behind 3003 aluminum tread plate and temper engineering transforms commodity buying into a precision-driven material strategy—delivering better, safer, and longer-lasting products.

https://www.aluminumplate.net/a/aluminum-tread-plate-3003-o-h12-h-14-h16.html