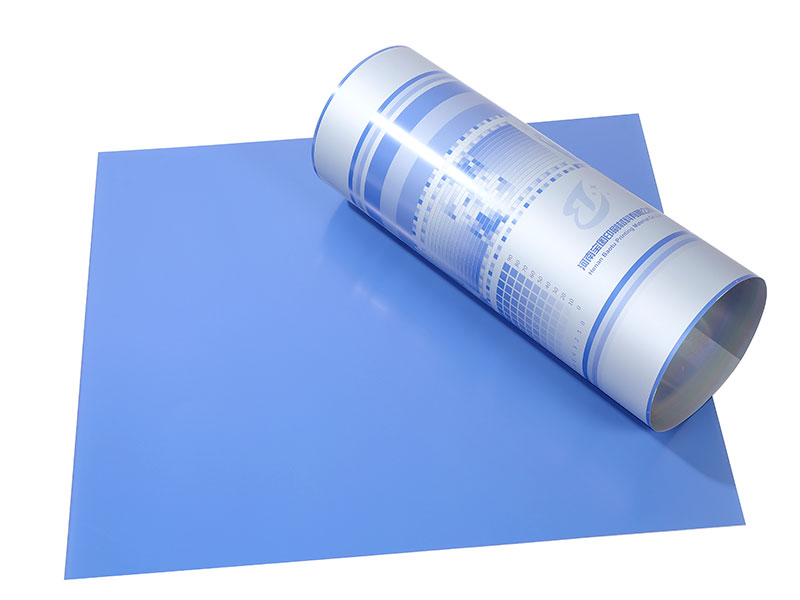

PS and CTP base aluminum plate

Aluminum plates are integral components in the printing industry, specifically in the production of printing images from plates based on Photopolymer Soft (PS) and Computer-to-Plate (CTP) technologies.

Understanding PS and CTP Base Aluminum Plates

PS and CTP aluminum plates function as printing surfaces, allowing offset printers to reproduce high-quality images efficiently. Both types take advantage of finely templated aluminum substrates that serve as the foundational platform on which images are transferred during the printing process.

PS Base Aluminum Plates

PS plates are designed for conventional printing methods. They are broadly used within offset lithography and linked directly to traditional printing workflows. The aluminum base in these plates is chemically treated to make it hydrophilic (water-attractive) on parts of the surface not meant to receive ink, whilst also retaining an ink-receptive layer. This chemical treatment enhances the ink transfer efficiency. Additionally, these plates offer longer press runs before wear and produce excellent image clarity with minimal dot gain, making them suitable for high-volume runs.

CTP Base Aluminum Plates

In comparison, CTP plates are utilized with modern technologies and are developed for direct exposure to laser light. They do not require intermediate processes such as film generation. CTP base aluminum plates lead to improved productivity as they develop faster and more consistently than conventional plates using alternative processing technologies. They lend digital precision to the printing process, resulting in remarkably accurate reproductions of detail, vibrant colors, and minimized registration errors.

Features of PS and CTP Base Aluminum Plates

-

Superior Print Quality: Both PS and CTP plates are engineered to deliver exceptional print quality, ensuring sharp images, vivid colors, and clean tonality across the entire print run. The seamless registration of the plates leads to crisp detailing that meets the demands of industries like advertising and publishing where aesthetic detail is key.

-

Enhanced Durability: Both types of aluminum plates exhibit high strength and resistance to deformation, contributing to their lifespan even under the stresses of multiple print cycles. This characteristic is essential for maintaining quality and performance stability.

-

Environmentally Friendly: Utilizing CTP technology ensures minimal waste during the imaging process. This reduction further promotes sustainability, aligning with industry trends towards greener practices. With more people moving towards reconsidering their ecological footprints, the adoption of PS and CTP aluminum plates emerges as an effective initiative in responsible manufacturing workflows.

-

Cost-effectiveness: Although initial setup costs may compare unfavorably with traditional means, PS and CTP plates save considerable time and resources through enhanced efficiency, better quality, and longevity – factors that collectively contribute to reduced overall production costs.

Applications of PS and CTP Base Aluminum Plates

-

Commercial Printing: Both plate types are critical for commercial printers who seek high-quality results for professional-grade publications, catalogs, magazines, and flyers.

-

Packaging Industry: Color fidelity and detail are immensely valuable in packaging; therefore, these aluminum plates have become the gold standard for branded packaging materials for consumer products.

-

Specialty Printing: From fine art printmaking to limited-edition publications, those requiring luxury-quality prints favor CTP for its superior fidelity and control.

-

Advertising and Promotion: Agencies and in-house marketing divisions often utilize PS and CTP plates to produce impactful visuals that attract customers. Instantaneous high-quality print jobs align perfectly with the fast-paced demands of advertising.

https://www.aluminumplate.net/a/ps-and-ctp-base-aluminum-plate.html