3105 H14 H16 Polished Mirror Aluminum

In the evolving landscape of modern manufacturing and design, aluminum alloys have transcended their traditional boundaries to become symbolizers of innovation, sustainability, and aesthetic excellence. Among these, the 3105 H14 and H16 polished mirror aluminum alloys distinguish themselves not merely through their physical properties but through their capacity to redefine how we perceive and utilize aluminum in various applications.

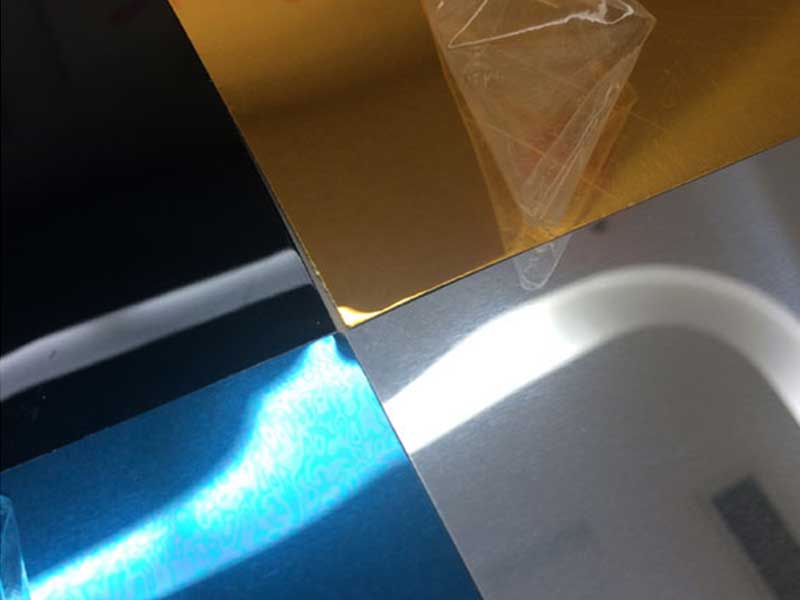

At first glance, polished mirror aluminum impresses with its captivating brilliance—like a sheet of frozen liquid metal reflecting the surrounding world with stunning clarity. Yet, beyond its luminous exterior lies a carefully orchestrated blend of material properties—product of specific alloy compositions, temper treatments, and manufacturing processes—that make it an unparalleled choice for both function and form.

The 3105 alloy is essentially an aluminum-manganese alloy. Manganese adds strength without significantly increasing weight, rendering this alloy an excellent candidate for applications demanding moderate strength, corrosion resistance, and formability. When tempered to H14 or H16, and subjected to high-polish mirror finishing, it becomes a versatile material balancing durability with eye-catching appearance.

Distinctive Dimensions of H14 and H16

The designations H14 and H16 specify the temper, indicating different degrees of strain-hardening and work-hardening levels:

H14: This half-hard temper offers a balanced combination of strength and ductility. It’s particularly suitable for applications requiring bending, shaping, or forming without cracking, all while maintaining high surface integrity. The polished appearance remains stable and uniform through additional forming processes.

H16: Slightly harder than H14, H16 temper provides increased strength and scratch resistance, lending itself well for exterior cladding and architectural finishes where longevity and style are paramount.

these subtleties allows designers and engineers to select the exact alloy temper that aligns with the project's functional and aesthetic demands.

Polished Mirror Finish: More Than Just Glamour

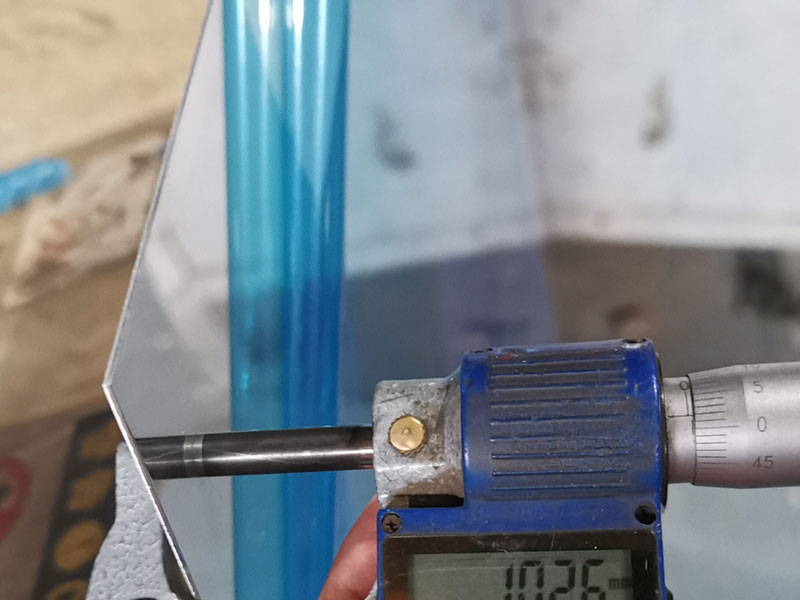

Achieving a mirror-like surface on 3105 alloy involves a meticulous process involving polishing, abrasion, and sometimes chemical treatments. This surface not only reflects light with extraordinary clarity but also enhances corrosion resistance by reducing surface imperfections where corrosion can initiate.

The mirrored finish elevates the alloy from mere construction material to a design element—appearing luxurious in interior spaces, dazzling as facade cladding, or serving as reflective panels for lighting efficiency. In transportation or electronics enclosures, the polished surface also acts as a barrier to environmental factors, helping extend the lifespan.

Sustainability in Design and Life Cycle

A distinctive aspect of 3105 H14/H16 polished mirror aluminum lies in its sustainability profile. Aluminum's inherent recyclability—up to 95% of the material can be recycled without loss of properties—aligns with the eco-conscious trends shaping industry choices today. When the exterior or interior finishes are polished, it does not hamper recyclability; instead, the surface still allows for sorting and processing.

Designers keen on green building standards, such as LEED certification, recognize this alloy as an eco-friendly solution—particularly valuable in architectural cladding, where minimal environmental impact with a high aesthetic yield counts as a significant advantage.

Practical Insights for Stakeholders

Architects and Interior Designers: Appreciate the amalgamation of beauty and durability, especially for feature walls, ceiling panels, or decorative facades that demand a resilient, mirror-like finish.

Manufacturers: Leverage the alloy's formability combined with the ease of achieving high-polished surfaces—optimizing processes such as roll forming, bending, or light stamping.

End Users: Benefit from long-lasting, maintenance-light surfaces that replicate newness over years, with easy cleaning and minimal corrosion concerns.

Final Reflection

In a conscious design ethos that values aesthetics, longevity, and sustainability, 3105 H14 and H16 polished mirror aluminum represent a refined choice. Their distinctive blend of versatility and visual appeal positions them uniquely—not merely as materials, but as reflections of a wider commitment to innovative, environmentally responsible design.

By embracing these alloys, stakeholders can turn structural necessities into artistic expressions—letting the mirror-like surfaces serve as both a statement of quality and a testament to progressive craftsmanship.

https://www.aluminumplate.net/a/3105-h14-h16-polished-mirror-aluminum.html