6061 6063 Color Coated Aluminum Sheet

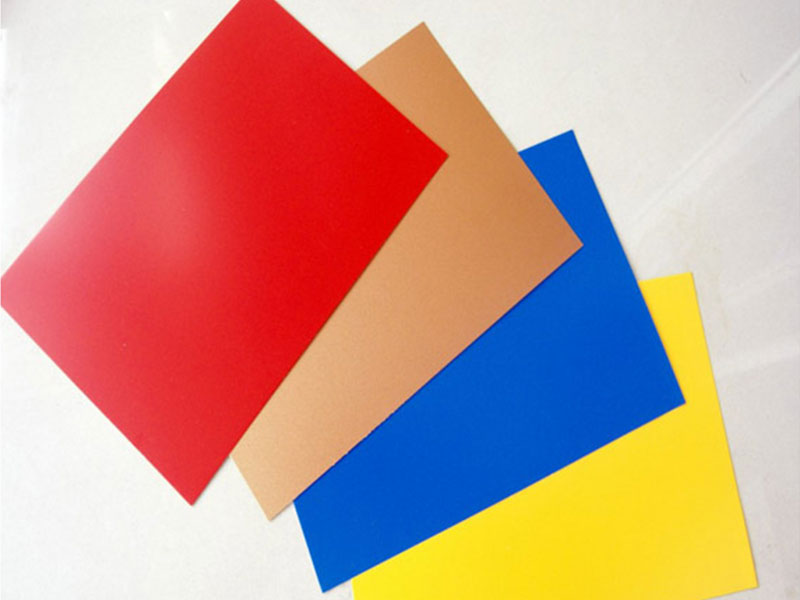

When it comes to selecting color coated aluminum sheets, customers often face a decision: should they go with 6061 or 6063 aluminum? Both alloys have found wide use in architectural, automotive, and industrial applications, especially when enhanced with durable color coatings. But how their distinct traits influence performance and aesthetics can help you make a smarter choice for your project.

Two Aluminum Alloys, Differentiated by Strength and Formability

6061 aluminum is an alloy prized for its excellent mechanical strength and good corrosion resistance. It contains magnesium and silicon, giving it a strong balance of toughness and versatility. This makes 6061 color coated aluminum sheet ideal where structural integrity matters — think load-bearing panels, protective covers, and robust outdoor installations.

On the other hand, 6063 aluminum offers superior extrudability and surface finish quality. Its formulation leans more heavily toward magnesium and silicon in softer amounts, making the alloy especially easy to shape into intricate profiles. The 6063 color coated aluminum sheet shines when used in architectural applications where smoothness and precision are — such as decorative cladding, window frames, or sunshades.

Why Color Coating Elevates Both Alloys

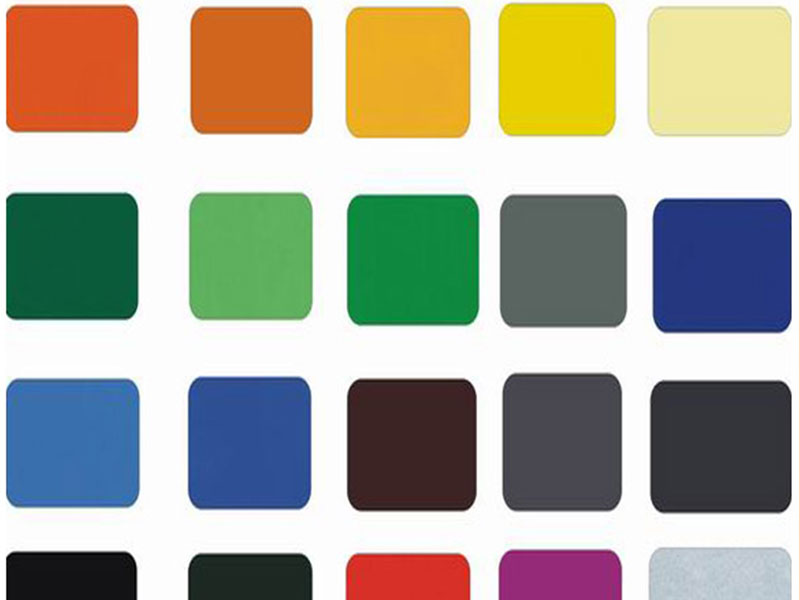

Color coated aluminum sheets aren’t just about looks. The coating system (typically polyester or PVDF) is designed to improve resistance against weather, corrosion, and UV degradation — critical factors for long-term outdoor use. Both 6061 and 6063 sheets take to the color coating well, but the purity and surface smoothness of 6063 often allow for a finer, more uniform finish.

If surface aesthetics are your highest priority, 6063’s naturally immaculate extrusion lends itself to a superior canvas for vibrant, consistent color coatings. Conversely, if your application requires that added strength underpinning the coating, 6061 stands firm.

Practical Customer Insights for Choosing Between 6061 and 6063

- Application Load Requirements: Opt for 6061 if your project demands higher mechanical strength.

- Design Complexity: When intricate shapes and smooth visible surfaces matter most, 6063 is your go-to alloy.

- Environmental Exposure: Both alloys offer good corrosion resistance, but the color coating significantly extends durability.

- Cost and Availability: 6063 tends to be slightly more expensive due to its finishing qualities; balance your budget with performance needs.

Bottom Line

6061 and 6063 color coated aluminum sheets both bring compelling qualities to the table. By viewing your project through the dual lens of functional strength and aesthetic finish, you can select the alloy and coating combination that truly fits your application's demands. Whether it’s the robust 6061 that supports your structure or the elegantly finished 6063 that beautifies your façade, color coated aluminum sheets provide a long-lasting, attractive solution.

This perspective reveals that the interplay between alloy composition and color coating not only clarifies differences but also empowers customers to align material choice with project goals effectively and confidently.

https://www.aluminumplate.net/a/6061-6063-color-coated-aluminum-sheet.html