6061 t6 polishing mirror aluminum sheet plate

When it comes to advanced manufacturing and design applications, the 6061 T6 polishing mirror aluminum sheet plate stands out as one of the industry's favorites. Celebrated for its stunning aesthetic appeal combined with intrinsic strength, this remarkable material finds its place in automotive, aerospace, and architectural sectors.

6061 T6 Aluminum: An Alloy to Trust

Chemical Composition

At the heart of the 6061 T6 aluminum sheet is its carefully crafted chemical composition. Typically, 6061 includes:

- Silicon (Si): 0.4% to 0.8%

- Iron (Fe): 0.0% to 0.7%

- Copper (Cu): 0.15% to 0.4%

- Manganese (Mn): 0.15% to 0.8%

- Magnesium (Mg): 0.8% to 1.2%

- Chromium (Cr): 0.04% to 0.35%

- Zinc (Zn): 0.25% max

- Titanium (Ti): 0.1% max

- Other Elements: 0.05% max each

The specific proportions create an alloy wars—highly suited for applications having demanding structural needs without compromising refined productivity or aesthetic qualities.

Tempering and Implementation Standards

The “T6” in 6061 T6 refers to its tempering process, an essential step for monolithic strength and stability. The T6 experience consists of two primary methods:

Solution Heat Treatment: This jejune process happens at high temperatures, where the aluminum alloy's molecular structure undergoes critical transformation, contributing strength and forming hardness.

Artificial Aging: Subsequent to solution treatment, the sheet is quenched and then aged at lower temperatures to optimize hardness further. Ultimately, it reaches a notable yield strength of approximately 270 MPa and tensile strength of about 310 MPa, making it durable yet manageable.

Compliance with ASTM B209 for aluminum plates and sheets ensures unity across production consistency, preserving industry standards worldwide. This guarantees accountability among suppliers whilst enhancing buyer confidence.

Physical and Mechanical Properties

The mechanical properties and resilience of the 6061 T6 polishing mirror aluminum sheet are attributes to investigate closely:

| Mechanical/Physical Property | Description |

|---|---|

| Ultimate Tensile Strength | 310 MPa (45,000 psi) |

| Yield Strength | 270 MPa (39,200 psi) |

| Elongation | 12 - 17% |

| Hardness (Rockwell) | RHB 95 min |

| Density | 2.70 g/cm³ |

| Electrical Conductivity | 30% IACS (International Annealed Copper Standard) |

| Coefficient of Thermal Expansion | 20 x 10^-6 /°C |

Our deep reinforces the light but strong surrounding surface advantages of utilizing 6061 T6 in various fields—from seamless facades in commercial architecture to structural reinforcements in the aeronautical realm.

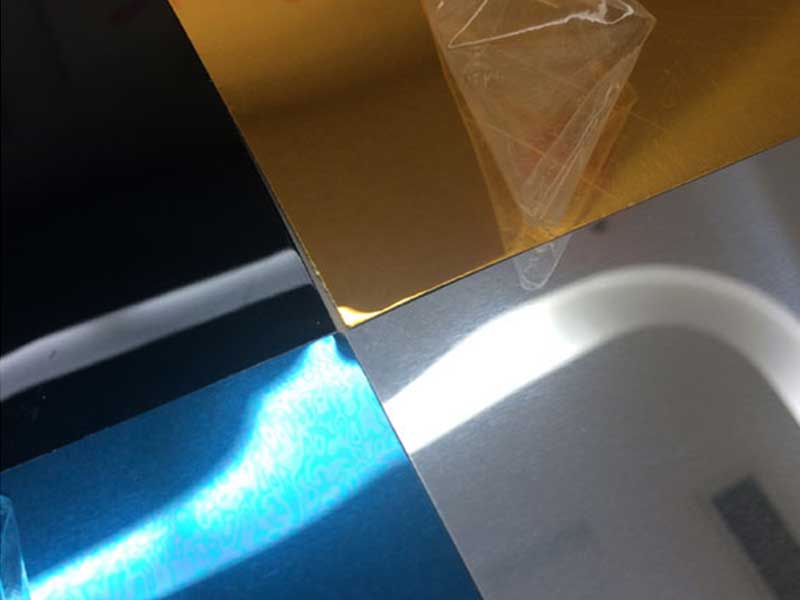

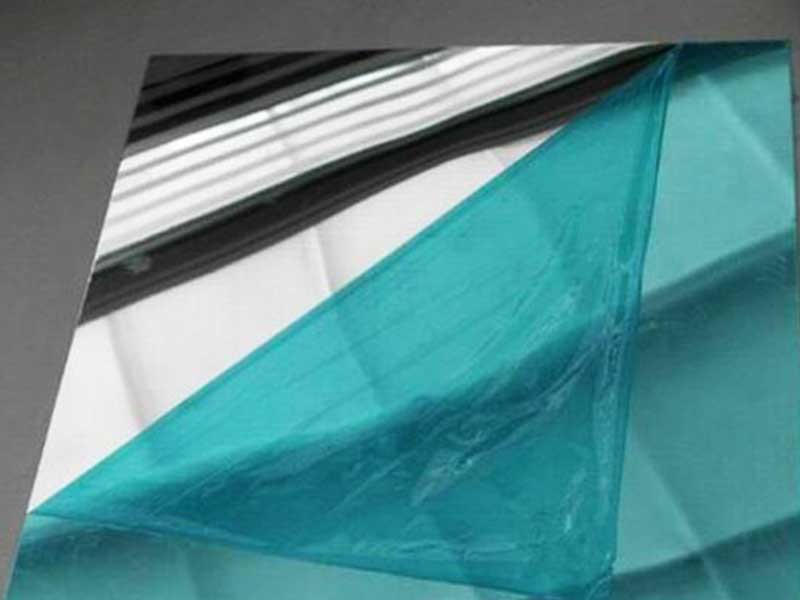

The Beauty of Polished Surface

Beyond raw performance lies the incomparable value derived from a polished mirror finish. This preprocessing treatment elevates the allure of 6061 T6 plates, making them appealing for various design-centric applications such as:

Architectural Facades: Balancing beauty and function, this mirror finish provides sparkle without igniting management concerns regarding wear and tear from the ordinary aesthetics of construction.

Artistic Installations: Acclaimed for reflecting ambient light, artistic structures crafted out of these sheets bring imaginative concepts to life, demanding admiration and inviting interaction.

Electronics and Equipment: Apart from aesthetic influences, the organization benefits greatly owing largely to the high reflectivity that usually leads to minimized heat absorption and escalation in reflective performance.

Versatile Applications of 6061 T6 Polishing Mirror Aluminum Piece

Its combination of properties suit applications where visual efficacy necessitates chance within stronger stress conditions. Some renowned implementations are:

- High-end home decor transformations

- Aerospace components with aerodynamic needs

- Marine structures resisting skin corrosion

- Automotive body panels manifesting glossy display properties

https://www.aluminumplate.net/a/6061-t6-polishing-mirror-aluminum-sheet-plate.html