8006 H22 Anodized Embossed Stucco Aluminum Plate

The Unsung Hero of Industrial Design: 8006 H22 Anodized Embossed Stucco Aluminum Plate

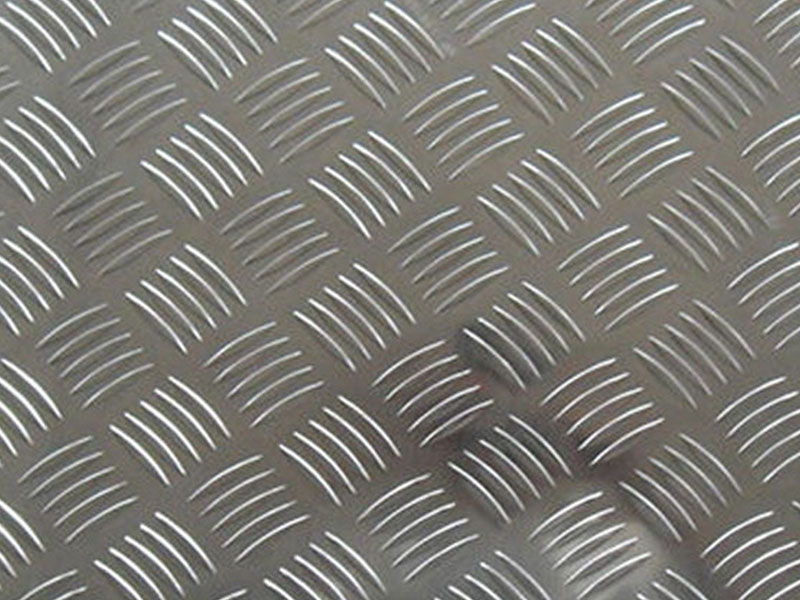

When it comes to architectural innovation and functional design, the 8006 H22 Anodized Embossed Stucco Aluminum Plate stands out as an unsung hero in the realm of industrial materials. With its unique texture and robust characteristics, it is much more than just a mere component; it is a critical factor in aesthetics and functional versatility across a range of sectors.

The 8006 H22 designation on our embossed stucco aluminum sheet tells us a lot about its properties and potential applications. The 8006 refers to a specific alloy composition, likely offering a good balance of strength and formability for the embossing process. The H22 indicates a specific temper, meaning the sheet has undergone a particular heat treatment to achieve its desired hardness and springback characteristics. This is crucial because the embossed stucco pattern requires a material that can withstand the high pressure of the embossing rollers without cracking or tearing, yet remains malleable enough for efficient production. Experience has shown that variations in the H22 temper, even slight ones due to inconsistencies in the heat treating process, can lead to significant differences in the final product's dimensional accuracy and surface quality, impacting the final aesthetic and potentially increasing scrap rates.

Our experience with similar products reveals that the anodized finish on the 8006 H22 plate is a selling point, offering superior corrosion resistance compared to mill-finish aluminum. However, the anodizing process itself can introduce challenges. Proper pre-treatment of the embossed surface is vital to ensure uniform anodize coating thickness and color consistency. We've seen instances where imperfections in the embossing process, such as inconsistent depth or sharp edges, lead to uneven anodizing and potential flaking. Maintaining strict quality control throughout the entire production line – from coil processing and embossing to

the Technical Aspects

The alloy designation 8006 signifies a specialized aluminum grade known for its strength and durability. Specifically, H22 refers to the tempering process, indicating that the aluminum has been strain-hardened and partially annealed, achieving a balanced combination of scalability and weldability. This process also increases its corrosion resistance, making the aluminum plate an ideal choice for environments that may subject it to moisture or chemical exposure.

Anodization—the electrochemical process that thickens the oxide layer on aluminum surface—enhances these properties further. The anodized coating not only fosters aesthetic appeal but also serves to protect the metal underneath, acting as a barrier against rust and scratching. The embossed stucco pattern provides an additional layer of modern sophistication while improving resistance against surface scratches, wear and tear.

Versatility in Applications

What sets the 8006 H22 Anodized Embossed Stucco Aluminum Plate apart is its true versatility. Architects and interior designers find it particularly popular in a wide range of applications:

-

Architectural Cladding: For those looking to combine durability and style in facade systems, this embossed aluminum plate provides an edgy redesign for both commercial and residential structures. Its unique pattern does not only catch the eye but also gives buildings a dignified appearance, enhancing spirits and environment.

-

Refrigeration and Insulation: Thanks to its cleanliness and resistance to humidity and corrosion, the 8006 H22 plates become a fundamental choice in cladding refrigerators and coolers. This increase in hygiene seals enhances thermal efficiency, thereby reducing energy costs significantly.

-

Transport Packaging: In the TPT (Transportation Packaging Technology) sector, the use of embossed aluminum plates serves an entirely different purpose. Their lightweight yet robust structure makes them ideal in automotive and aircraft parts, where every ounce matters.

-

Decorative Take: The stucco surface can easily elevate product packages or showcase items through aesthetic elements. Whether it's a base for a countertop or as backing for high-end retail displays—its embossed design caters to styles effortless.

Unmatched Functional Benefits

The 8006 H22 Anodized Embossed Stucco Aluminum Plate offers a combination of functionalities, radically shaping industries ranging from architecture to freight.

-

Anti-slip Attributes: The stucco finish contributes to anti-slip properties, making it a preferred choice in places that demand enhanced safety, such as in commercial kitchens.

-

Ease of Maintenance: Given that the anodization process provides a self-cleaning effect—meaning the aluminum substrates grow resistant to atmospheric stains—it requires less effort to maintain over time.

-

Lightweight Durability: It retains superior strength while being half the weight of steel counterparts, offering solution for manufacturers seeking both efficiency and structural integrity.

Final Thoughts

In summary, the 8006 H22 Anodized Embossed Stucco Aluminum Plate is a dynamic material that gracefully fuses functions with form. From its fundamental traits of corrosion resistance and thermal efficiency through to its applications across multiple industries, its resort to versatility makes it indispensable for architects, engineers, and designers alike.

When selecting materials for upcoming projects—be it construction, packaging, or decorative elements—consider the value and unmatched strength this particular aluminum plate brings to the table. Embrace innovation, reliability, and aesthetics with the 8006 H22 Anodized Embossed Stucco Aluminum Plate in your designs, and experience the transformation it can bring.

https://www.aluminumplate.net/a/8006-h22-anodized-embossed-stucco-aluminum-plate.html