8011 aluminum foil for medical bottle cap

When it comes to healthcare product packaging, safety, integrity, and hygiene are paramount. 8011 aluminum foil has emerged as a popular choice for medical bottle caps due to its remarkable properties.

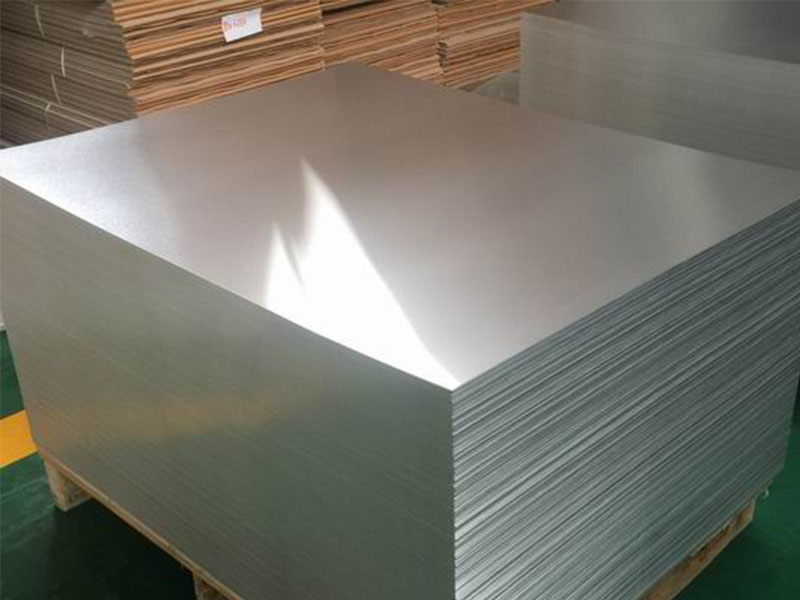

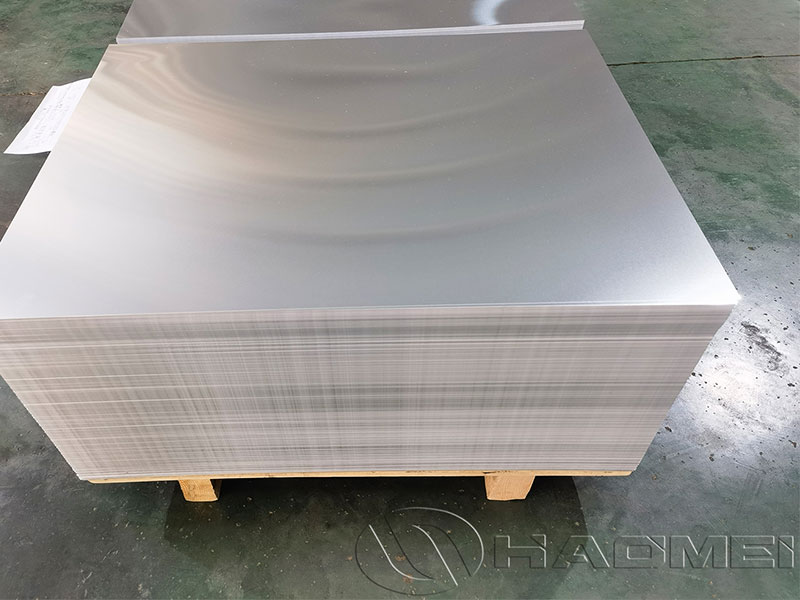

8011 Aluminum Foil

Before we delve deeper, l

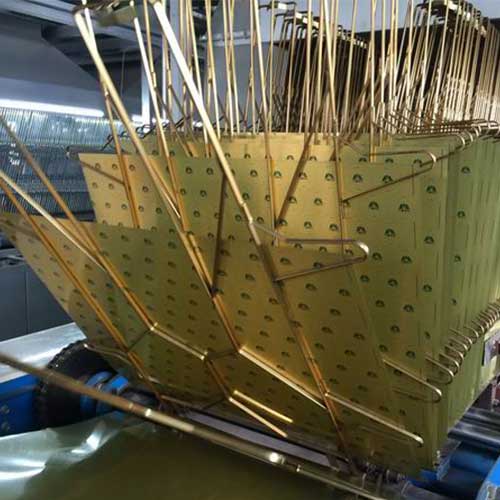

From a production standpoint, 8011 aluminum foil's suitability for medical bottle caps is a complex issue. We see firsthand the challenges in achieving the necessary thinness and consistent temper for reliable sealing performance. The slightest variation in gauge can drastically impact the forming and sealing process, leading to rejects and potentially compromising the integrity of the medical product. Our team constantly monitors the alloy composition and annealing processes to minimize these variations. We're also heavily invested in optimizing our tooling to handle the delicate nature of the foil, ensuring a consistently precise and reliable cap formation without tearing or cracking. Maintaining a sterile environment during processing is paramount, and we're constantly evaluating and improving our cleaning and handling protocols to meet the stringent demands of the medical industry.

Beyond the technical aspects, the cost-effectiveness of 8011 for this application is always a consideration. While it offers desirable properties like formability and corrosion resistance, it might not always be the most economical choice compared to other alloys or materials. We're constantly evaluating alternative materials and manufacturing processes to find the optimal balance between performance, cost, and yield. This involves close collaboration with our clients to understand their specific needs and constraints, often leading to tailored solutions and customized foil specifications for improved efficiency and reduced waste. The pressure to deliver high quality at competitive prices keeps our team constantly striving for improvement in every aspect of the production process.

Non-Toxicity and Hygiene Assurance

One of the foremost requirements in medical product packaging is non-toxicity. The 8011 aluminum foil satisfies this critical criterion, making it an ideal material for caps that secure medicines or other health-related liquids. Its high barrier properties protect the contents from exposure to air, moisture, light, and microbial contaminants, thus maintaining product efficacy and safety.

Strength and Durability

Unlike many mass-produced packaging materials, 8011 aluminum foil offerings is know due to their outstanding mechanical strength. A wide range of physical tests demonstrates that it remains unyielding under performance demands, despite temperature differences and potential physical impact. This inherent resilience becomes particularly advantageous in healthcare settings, where shock-resistant packaging can prevent spillage or contamination.

Applications in Medicine

The applications of 8011 aluminum foil are extensive across various domains within medical packaging. Let's explore some prevalent applications:

Pharmaceutical Bottles

Perhaps the most common use of 8011 aluminum foil is as protective seals or caps for pharmaceutical bottles. In these settings, the foil ensures that upon opening a sealed bottle for the first time, the contents remain uncompromised while preventing inadvertent tampering. The controlled release feature buoyed by the foil creates peace of mind for consumers and manufacturers alike.

Nutraceuticals and Supplement Industry

With the rise of wellness and dietary supplements, healthcare producers leverage 8011 aluminum foil for bottle capping due to its ability to thwart moisture and atmospheric intrusion, thus maintaining high-performance results over prolonged storage periods. Long shelf life equates to satisfied consumers who return time after time.

Medical Devices and Labs

In more specialized areas, medical devices that require stringent purification routines—like just-in-time manufacturing—can benefit from the sealing of individual components with 8011 aluminum foil. Its crisp sealing abilities further cement its role in quality and safety assurance within laboratory environments.

The Technical Advantages of 8011 Aluminum Foil

Integrating various practical benefits, the technical attributes of 8011 aluminum foil commend its selection for medical bottle caps:

-

Excellent Barrier Properties: With impermeability to liquids and undesirable gases, 8011 aluminum assures rigorous containment of vial contents even in varied environmental conditions that could affect the chemical makeup of pharmaceuticals.

-

Thermal Conductivity: Possessing good thermal properties also adds to its value, as hot fills with stringent hot pressure settings warrant careful management, ranging in temperate response and structural engagement.

-

Easy Printing: Unlike other materials, the exterior of 8011 aluminum foil accommodates variable retention levels of ink on its surface. This quality opens doors for relatable branding without sacrificing production integrity.

Been integrated into structural and functional qualities while responding kindly to friction, 8011 aluminum foil encapsulates versatility, performance-demand conformity, and determination over the currently available packaging options in medicine.

https://www.aluminumplate.net/a/8011-aluminum-foil-for-medical-bottle-cap.html