Aluminum Mirror Sheet 1100 1050 1060

Unveiling the Reflective World of Aluminum Mirror Sheet: A Deep Dive into Grades 1100, 1050, and 1060

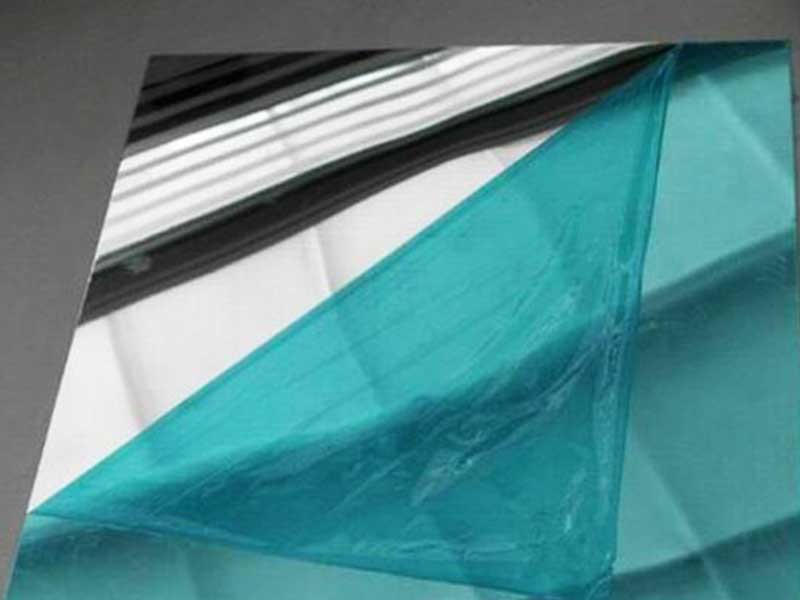

Aluminum, known for its lightweight and corrosion-resistant properties, has found an unexpected yet significant role in reflective applications. Among the varieties produced worldwide, the Aluminum Mirror Sheet in grades 1100, 1050, and 1060 stands out due to its unique attributes and versatility.

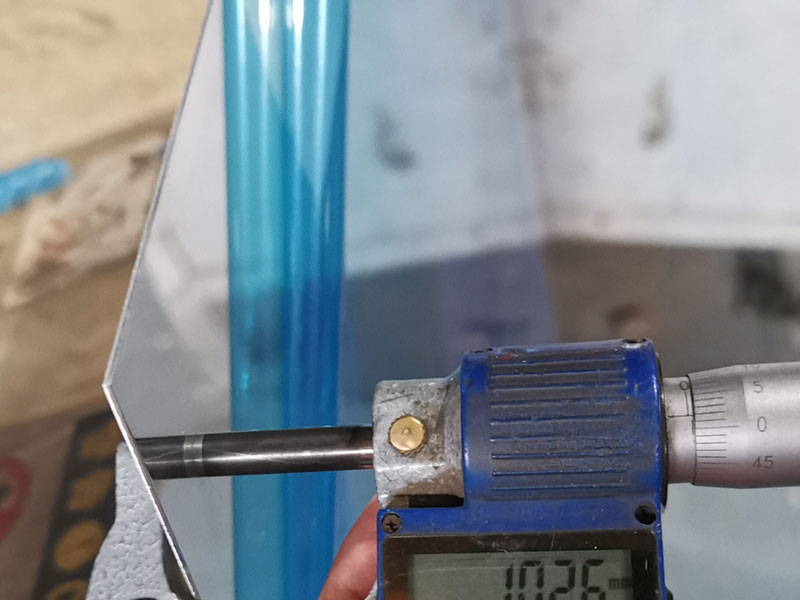

Working with 1100, 1050, and 1060 aluminum alloys for mirror sheet production reveals some interesting nuances. While all three are known for their high reflectivity after polishing, we find subtle differences in workability. The 1100, being nearly pure aluminum, is the easiest to handle, exhibiting excellent formability and ductility. This makes it ideal for intricate shapes or complex bending processes, though its slightly softer nature requires extra care during handling and polishing to prevent scratching. Conversely, the 1050 and 1060 alloys, containing small amounts of other elements, show slightly improved strength and hardness which can be advantageous for larger, more robust applications where potential bending stress is higher. However, this increased strength translates to slightly reduced formability demanding more precise tooling and techniques during manufacturing.

The Reflective Revolution of Aluminum Sheet

Aluminum Mirror Sheets are a gem in industries requiring both functionality and beauty. Their primary function extends beyond mere aesthetics; they are instrumental in enhancing brightness, improving visibility, and reflecting light effectively. With an reflective rate, usually exceeding 85–90%, they enable optimal light distribution in a variety of environments.

Technical Breakdown:

-

Aluminum 1100: Recognized for its excellent workability and corrosion resistance, this alloy’s strength comes from its pure aluminum composition, making it ideal for chemical processing and food handling environments. With a reflectivity of around 87%, 1100 is best utilized in applications where flexibility and aesthetics play crucial roles.

-

Aluminum 1050: This grade is similar to 1100 but offers enhanced strength over cold-worked connections. Weighing only a fraction of heavier materials, 1050 serves not only in decorative applications but also plays a vital part in energy efficiency, particularly in lighting fixtures, mirrors, and architectural elements. Its reflective characteristics make it a prime choice for manufacturing sleek and modern design elements.

-

Aluminum 1060: Ma utics about one of the most popular alloys due to its high thermal and electrical conductivity. 1060’s characteristics allow it to maintain superb reflective qualities whilst being more demanding concerning machining. This uniqueness lends it well to specialized applications such as vacuum plating and OLED systems where consistent reflectivity is paramount.

Vibrant Applications Across Industries

The potential of Aluminum Mirror Sheets stretches far beyond artful home décor. A contribution to their popularity is that they serve several industries with remarkable performance and lightweight designs.

-

Architectural Applications: In contemporary construction, architects utilize aluminum mirror sheets to create visually stunning surfaces that enhance building façades. Graded accordingly, they reflect the intrigue of their surroundings and invite natural light into spaces. For instance, Aluminum 1050 is favored for cladding, as it marries durability with aestheticismo.

-

Lighting and Luminaires: The role of reflectivity cannot be understated within the lighting industry. Aluminum Mirror Sheet alloys command constant use in manufacturing reflective tiles in lighting fixtures, amplifying light output while minimizing energy consumption—creating spaces that are both bright and inviting.

-

Signage and Displays: In advertising, reflecting surfaces capture attention and direct focus. Businesses preferentially utilize 1100 and 1060 aluminum mirror sheets for sign backings, providing engaging, visually appealing displays designed to pique interest rapidly.

-

Automotive Components: Mirror aluminum sheets engage functionality in automotive imaginations as well as stylistic perfectness. Their high reflectivity aids in reflectors that drive safety in vehicular designs without adding unnecessary weight.

-

Safety Features: In applications where safety cannot be compromised, these mirror sheets are deployed in the interior of buildings, producing reflections that enhance one's awareness of surrounding areas, enhancing pedestrian and vehicle movements.

https://www.aluminumplate.net/a/aluminum-mirror-sheet-1100-1050-1060.html