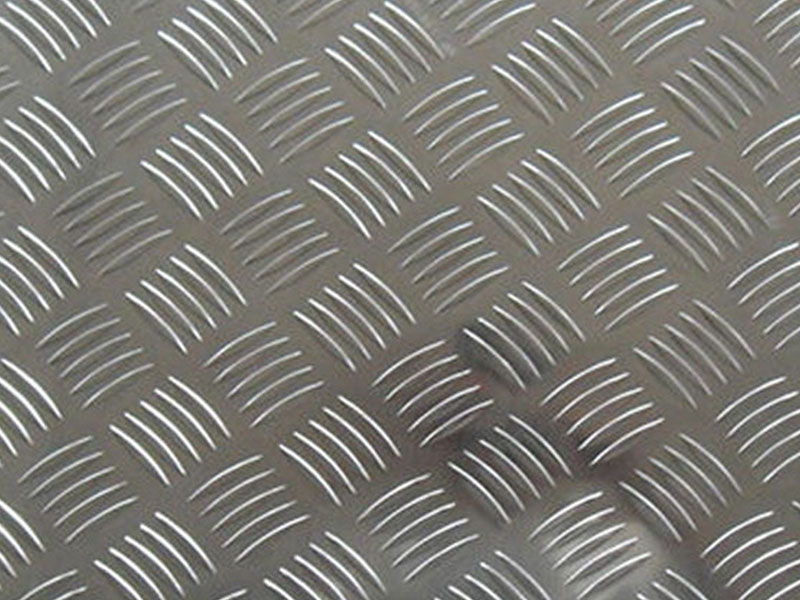

Aluminum tread plate 1050 1060 1100 1070 3003 3004

When one thinks of aluminum tread plates, the immediate association often pivots around practicality, safety, and a non-slip surface.

Aluminum Alloy Designation

Each aluminum alloy undergoes a process of delineation based on its elemental components and its intended application, reinforced by the American standard designations. At first glance, these numbers might seem just another layer of technicality, yet they reveal volumes about the properties and performance benchmarks of aluminum tread plates across various industrial sectors.

A Closer Look: Features of Alloys

- 2000 Series:

- Aluminum alloys starting with “10xx” indicate commercially pure aluminum. In tread plate varieties, both 1050 and 1060 consist of 99.5% and 99.6% Aluminum respectively.

- Applications: Furniture and decor where weight and corrosion resistance are more critical than strength.

- Advantages: Outstanding ductility and lightweight enhancement without extensive structural support, which makes handling easier.

- 2000 Series:

- 1100 aluminum offers approximately 99% aluminum content, showcasing exceptional workability and corrosion resistance but moderate mechanical properties relative to higher alloy groups.

- Applications: Can be utilized in chemical processing, milk handling, food preparation, and storage applications.

- Unique Feature: Its excellent thermal conductivity complements industries reliant on widespread heat transfer—which can inherently be enhanced to undergo high-temperature processes.

- 3000 Series:

- Enter the 3000 series with 3003 and 3004, distinguished by their addition of manganese which tends to lend substantial strength and formability, critical traits for footwear and underside safety mats.

- Applications: These alloys fit flawlessly in manufacturing decorative panels and infill chips for structural elements that also insist on aesthetic appeal.

- Noteworthy Attribute: Particularly resistant to atmospheric corrosion, promoting seamless application environments in high-humidity areas such as gymnasiums and swimming pools.

- 1100 Base with Enhanced Iron:

- L

- Applications: Commonly imported into electrical and lifting patterns while demanding lightweight requirements and slipping precautions.

Condition Evaluation: Intrinsic Value Proposition

Transitioning from technical specifications to day-to-day relevance—gaining inherent value lies at the core of selecting the right alloy. Load-bearing routes favor textured plates crafted from higher-paced alternatives (like 3003 for enhanced strengths), presenting mechanization compatible with abrupt directional change during delivery appraises. More lightweight alternatives like 1050 or 1060 suited less-demanding applications exquisitely regardless of user purposes—the breadth gives way to agility thus simplifying customization along derivative aspects.

Working with aluminum tread plate alloys 1050, 1060, 1100, 1070, 3003, and 3004 daily reveals distinct performance characteristics crucial for choosing the right material for a specific application. The 1000 series alloys (1050, 1060, 1070, 1100) are known for their excellent corrosion resistance and high ductility, making them ideal for applications requiring formability and resistance to atmospheric exposure. However, their lower strength compared to the 3000 series limits their use in high-stress environments. I've seen instances where 1050, chosen for its ease of welding in a specific project, resulted in slightly more deformation during the forming process than expected, highlighting the need for careful material selection based on the entire manufacturing process.

The 3000 series alloys, specifically 3003 and 3004, offer a significant strength advantage over their 1000 series counterparts due to the addition of manganese. This makes them suitable for applications requiring greater load-bearing capacity, although their corrosion resistance is slightly lower. We've found that 3004, with its slightly higher strength and work-hardening capability, is preferred for applications with more complex forming requirements or higher anticipated wear. However, this added strength

Distinctive Comparison Matrix

Rather than renaming ambiguous attributes, this systemic walkthrough plots an evident associated ladder denoting suited environments/test installations. Categorically, one might forgive a sum assessment chased against numerical contexts instead:

| Alloy | Al Content | Strength | Ductility | Corrosion Resistance | Major Applications | |

https://www.aluminumplate.net/a/aluminum-tread-plate-1050-1060-1100-1070-3003-3004.html