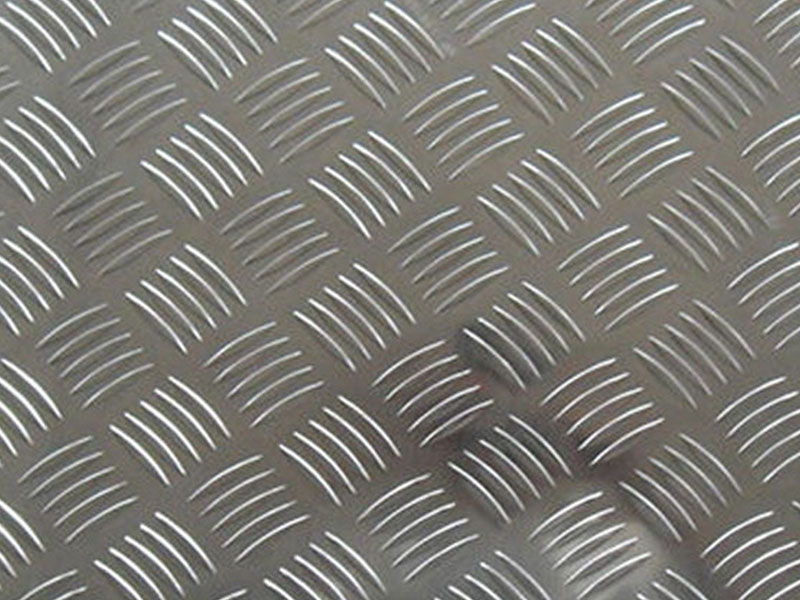

Embossed aluminium sheet 1100

In the fascinating world of materials, embossed aluminium sheet 1100 stands out as a remarkable choice for both aesthetic enhancement and functional application.

The Technical Profile

To better understand embossed aluminium sheet 1100, it is essential to grasp the composition and manufacturing intricacies involved. The 1100 series of aluminium is renowned for its high corrosion resistance, good workability, and ability to withstand complex environmental conditions. The sheets in this series typically contain a minimum of 99.0% aluminium content, ensuring a lightweight and durable product, which simultaneously offers excellent thermal and electrical conductivity.

Working with 1100 aluminum sheet for our stucco embossed products presents a unique set of challenges and rewards. Its softness, while making the embossing process relatively straightforward and yielding a crisp, clean detail on the finished product, also means we have to be meticulous in handling it to avoid scratching or marring the surface. We've experimented with different roller pressures and lubricant types to optimize the embossing process and minimize material waste. A slight adjustment in the roller gap can dramatically affect the final depth and clarity of the stucco pattern, so consistent calibration and ongoing quality control are paramount. The inherent reflectivity of the 1100 alloy also dictates our finishing processes, requiring specific cleaning methods to prevent streaking or discoloration after embossing.

Beyond the technical aspects, I've come to appreciate the versatility of 1100 aluminum in this application. Its corrosion resistance is crucial for our outdoor building products, and its lightweight nature makes it easier and safer for our workers to handle. Recently, we've been different surface treatments to enhance the stucco finish, including powder coating and anodizing, and the 1100 alloy lends itself well to these processes. Seeing the final product, a beautiful, durable embossed sheet used on everything from architectural facades to decorative panels, is incredibly rewarding, knowing the meticulous work and careful consideration that went into its creation.

Upon embossing, the unique textured surface of these sheets not only elevates aesthetic appeal but also significantly enhances the sheet’s resilience. The embossing process creates a series of raised or depressed patterns, which increases surface area coefficients and potentially alters physical characteristics such as heat dissipation and sound insulation.

Diverse Functions

One of the most compelling aspects of the embossed aluminium sheet 1100 is its multifunctional capabilities. Here we explore its uses in different sectors:

-

Architectural Applications: The foil-like sheen combined with customizable patterns provides architects and designers with opportunities to personalize building facades and interior finishes. It's commonly used for wall cladding, ceilings, and decorative finishes in both residential and commercial buildings. The embossed surface further improves scratch and dent resistance, adding to its long-term durability.

-

Automotive Industry: In the automotive landscape, lightweight materials are crucial for improving efficiency and performance. Embossed aluminium sheet 1100 is extensively employed in vehicle interiors and exteriors, replacing heavier materials. Its embossing technique results in both acoustical and thermal insulation, making it ideal for engine covers and cabin panels.

-

Electronics: Manufacturers find embossed aluminium sheets to be fantastic choices for electronic cases. The design facilitates passive cooling, drawing heat away from sensitive components. Also, the sheets' non-reactive characteristics ensure safe and reliable use surrounding electronic circuitry.

-

Packaging: Notably, embossed aluminium sheets also find applications in high-end packaging solutions. They are adept at producing visually striking elements for premium products, combining protection with vibrancy and elegance.

Environmental Advantages

embossed aluminium sheet 1100 from a sustainability angle introduces its eco-friendly credentials. Firstly, aluminium is an extremely recyclable material. The process of recycling aluminium uses only 5% of the energy required to produce virgin aluminium, making it a sustainable choice. In terms of construction or product design, utilizing this material aligns with global initiatives aimed at reducing energy consumption while enhancing livable environments.

Concluding Thoughts

In conclusion, embossed aluminium sheet 1100 exemplifies an intriguing balance between functionality and aesthetic appeal. Its technical specifications catalyze a multitude of applications that solidify its status as a go-to material across diverse industries, from automotive to architectural design. As the demand for innovative structures and designs continues to grow, the profound impact of such materials becomes increasingly crucial.

Embossed aluminium sheet 1100 not only enriches our built environment but also embodies modern principles of sustainability and design ingenuity.

https://www.aluminumplate.net/a/embossed-aluminium-sheet-1100.html