Embossed aluminum sheet Dc cc 1100 1050 1060 1070

Embossed Aluminum Sheet DC CC Series (1100, 1050, 1060, 1070): A Comprehensive Insight into Functions, Applications, and Technical Excellence

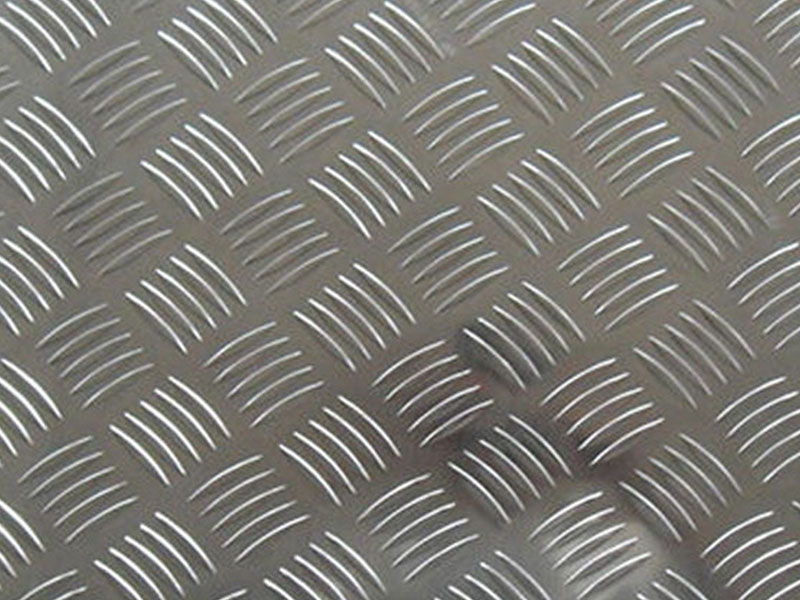

Embossed aluminum sheets from the DC CC (Direct Chill Continuous Casting) series have gained prominent industrial acceptance due to their outstanding combination of lightweight strength, corrosion resistance, exquisite aesthetics, and ease of fabrication. Specifically, the 1100, 1050, 1060, and 1070 alloys are among the most commonly adopted grades when embossing patterns like stucco finishes onto aluminum coils or sheets.

What Is Stucco Embossed Aluminum Sheet in the DC CC Alloy Series?

Embossed aluminum sheets in grades 1100, 1050, 1060, and 1070 primarily stem from the aluminum DC CC process, which involves melting high-purity aluminum, casting solid billets, and rolling them into sheets. The “stucco” embossing pattern is characterized by a textured random pattern of low, rounded reliefs giving a non-slip and decorative appearance. The embossing process involves precise mechanical rolling with patterned rollers under controlled pressure and temperature to maintain mechanical integrity while enhancing surface functionality.

Alloy Composition and Chemical Properties

These alloys mainly consist of commercial purity aluminum differing only slightly in total aluminum content and permissible alloying elements. Their hallmark is excellent corrosion resistance because of the near absence of major alloying metals — as such, they maintain recyclability and long life spans in variable environments.

| Alloy | Al (%) | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Ti (%) | Others (%) |

|---|---|---|---|---|---|---|---|---|---|

| 1100 | Min 99.0 | 0.12 | 0.3 | 0.05 | 0.050 | 0.03 | 0.10 | 0.03 | 0.05 max total |

| 1050 | Min 99.5 | 0.05 | 0.40 | 0.05 | 0.05 | 0.03 | 0.10 | 0.03 | 0.05 max total |

| 1060 | Min 99.6 | 0.05 | 0.12 | 0.03 | 0.03 | 0.03 | 0.10 | 0.03 | 0.05 max total |

| 1070 | Min 99.7 | 0.05 | 0.12 | 0.05 | 0.03 | 0.03 | 0.05 | 0.02 | 0.03 max total |

Temper Designations & Mechanical Characteristics

DC CC embossed aluminum sheets are typically supplied in various temper conditions, influencing mechanical strength, ductility, and workability. Common tempers include:

- O (Annealed): Soft, maximum ductility, best for heavy embossing and forming.

- H14: Strain hardened and partially annealed, offering enhanced strength but retaining moderate formability.

- H16, H18: Range from harder tempers offering superior mechanical strength but reduced ductility.

| Alloy | Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| 1100 | O | 55-110 | 35-70 | >= 25 |

| 1050 | H14 | 90-120 | 55-85 | 10-20 |

| 1060 | O | 55-100 | 30-70 | 20-25 |

| 1070 | O | 55-90 | 25-60 | 20-25 |

Implementation Standards

Embossed aluminum sheets from DC CC alloys align with international manufacturing and testing standards ensuring uniform quality, performance, and compatibility:

- ASTM B209: Standard specification for aluminum and aluminum-alloy sheet and plate.

- JIS H4100: Japanese standard covering chemical and mechanical requirements for aluminum sheets.

- EN 485-2: European Norm specifying technical conditions for inspection and delivery of aluminum flat products.

Each standard guides dimensional tolerances, thickness, flatness criteria, polishing (surface finish grades), associated with embossing.

Functional Advantages of Stucco Embossed DC CC Aluminum Sheets

Enhanced Anti-Slip SurfaceThe stucco embossing creates a tactile surface with superior friction properties — ideal for flooring, truck bodies, elevator doors, stair treads, and walkways requiring slip resistance.

Improved Aesthetic AppealReflective textured patterns scatter harsh glare, affording an attractive finish highly sought in architectural cladding, decorative facades, and consumer appliances.

Corrosion and Weather ResistanceNatural oxide layers on high-purity alloy sheets paired with pattern embossing prevent stagnation of moisture, mitigating corrosion risk and enriching lifespan under moist, outdoor conditions.

Lightweight Structural UtilityStrong for weight but easy to cut and form, the DC CC series in stucco format facilitates transport vehicle mass reduction and kinder-install facades with load-bearing grid support.

Easy MaintenanceEmbossed aluminum resists fingerprinting, staining, and abrasion; its easy-to-clean characteristic tremendously reduces BFS (building façade services) costs.

Applications

- Transportation & Automotive: Side walls of trailers, truck panels, loading ramp covers benefiting from embossing's stiffening effects and slip-hardening.

- Construction Industry: Roofing sheets, doors, perimeter fences, elevator panels where exceptional corrosion resistance complements aesthetic patterns.

- Household Appliances: Outer panels for refrigerators, microwaves enhanced with embossed textures for elevated visual and tactile quality.

- Packing and Ductwork: Protected foil linings where embossing improves powder adhesion in finishing workflows.

https://www.aluminumplate.net/a/embossed-aluminum-sheet-dc-cc-1100-1050-1060-1070.html