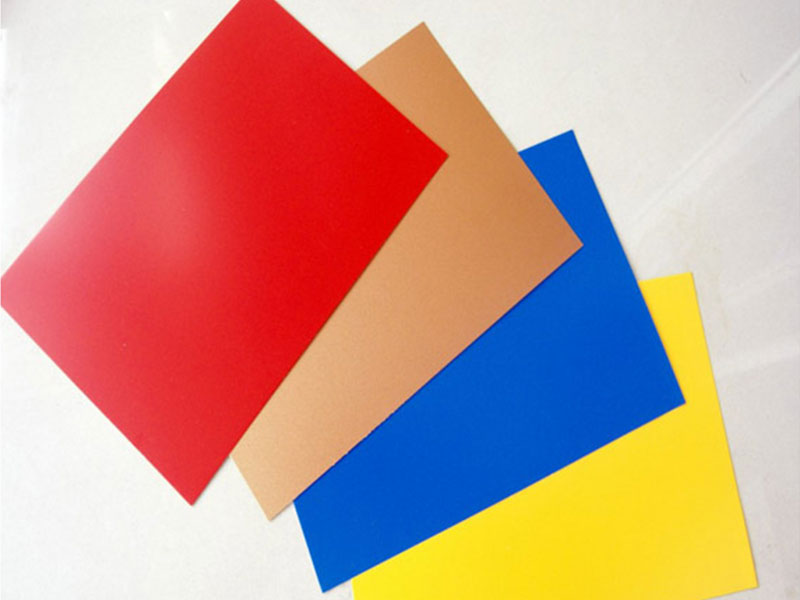

Powder Painted Color Coated Aluminum Sheet

Powder Painted Color Coated Aluminum Sheet: The "Finished Product" Mindset (Not Just a Metal Sheet)

Most buyers evaluate color coated aluminum sheet by thickness, alloy, paint brand, and price. That's important-but it misses the point: powder painted color coated aluminum sheet should be treated as a finished surface product, not a semi-finished metal. When you think like an end-user (installer, fabricator, and building owner), your choices become clearer, and costly mistakes drop sharply.

Below is a practical, customer-friendly way to understand what matters.

1) What It Really Is (in plain words)

Powder painted color coated aluminum sheet is an aluminum sheet coated with dry powder (resin + pigments + additives) that is electrostatically sprayed and oven-cured into a solid, durable film.

Compared with wet paint coatings, powder coating is valued for:

- Thicker, more uniform film (often beneficial for edges and impact resistance)

- No solvent evaporation (low VOC, cleaner process)

- Good scratch and abrasion resistance in many systems

2) A Different Way to Buy: "Surface Performance First"

Instead of starting with alloy, start with where and how the sheet will live:

A. Outdoor architectural (facades, cladding, canopies)

Your real enemy is UV + weathering, not the aluminum.

- Ask for UV-stable powder systems (commonly polyester-based for exterior use)

- Confirm color retention expectations and warranty terms

- Choose finishes that hide dust and rain marks (matte or textured often helps)

B. Signage & decoration

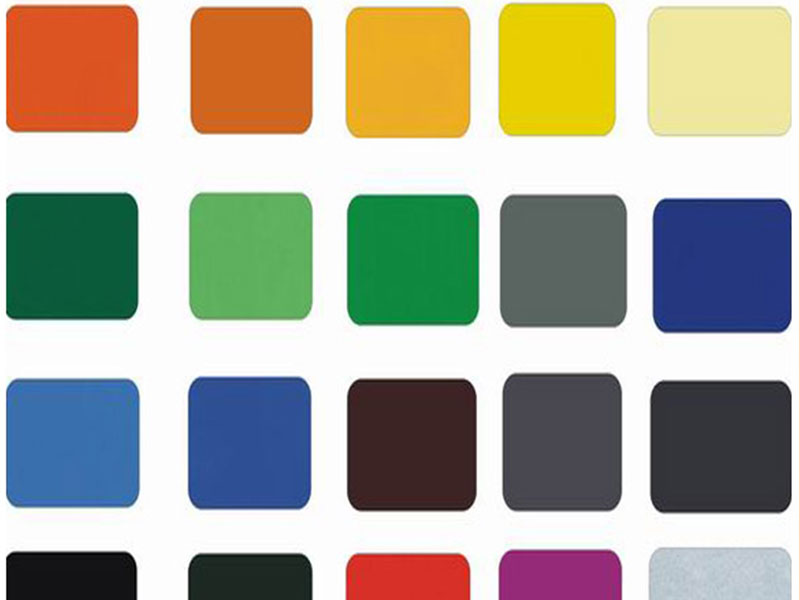

Your enemy is appearance inconsistency (batch variation, gloss mismatch).

- Specify gloss range, texture type, and color standard (RAL / Pantone / physical sample)

- For large projects, require batch control and a retained "golden sample"

C. Industrial housings, transportation, equipment covers

Your enemy is impact + chemicals.

- Focus on hardness, abrasion, and chemical resistance

- Clarify exposure: oils? cleaning agents? salt spray? fuels?

This "surface-first" method prevents buying a great sheet that fails in the real environment.

3) Powder Coating vs. Coil Coating: Don't Mix Up the Use Case

Customers often compare powder painted sheet with PVDF/PE coil-coated aluminum.

A practical distinction:

- Powder painted sheet: excellent for custom colors, smaller batches, thicker films, strong edge coverage, and robust physical durability.

- Coil coating (PVDF/PE): excellent for high-volume uniformity and long-proven architectural systems (PVDF especially for premium exterior color stability).

If your project needs many colors, fast switching, or textured finishes, powder coating is often the more flexible solution.

4) Details That Quietly Decide Quality

These are the "hidden variables" that determine whether a sheet looks good after fabrication and after 3–5 years outdoors.

Film thickness (and consistency)

- Too thin: weak hiding power, poor durability

- Too thick: risk of orange peel, reduced sharpness of edges, possible chipping in severe forming

Ask for the supplier's target thickness range and inspection method.

Pretreatment (the foundation under the paint)

Many coating failures are actually pretreatment failures (poor adhesion, blistering, corrosion creep).

- Ask what pretreatment is used (and whether it's suitable for your environment)

- For outdoor use, corrosion protection at cut edges matters

Gloss and texture control

Two sheets can be the "same color" but look different due to gloss/texture.

- Specify gloss level (e.g., matte, satin, high gloss)

- Specify texture (smooth, fine texture, sand texture, wrinkle)

Edge performance after cutting

Cut edges are where moisture and corrosion start.

- Discuss how the coating behaves at edges and whether additional sealing is needed in your installation

5) Forming and Fabrication: "Paint + Metal" Must Work Together

A powder painted sheet isn't just coated-it must still be bent, punched, or riveted.

Before ordering, clarify:

- Minimum bend radius expectations

- Whether the coating is designed for post-forming

- Protection film options for transport and fabrication (and whether adhesive residue risk is controlled)

If your job involves tight bending or deep drawing, confirm test results or trial samples.

6) The Simple Checklist Customers Can Use

When requesting a quote or comparing suppliers, ask these six questions:

- Is the powder system interior or exterior grade?

- What pretreatment is used, and what corrosion performance is targeted?

- What is the coating thickness range and how is it measured?

- What gloss/texture standard will be followed (and can you provide a control sample)?

- Can it handle my fabrication process (bending, punching), and what's the recommended bend radius?

- What packaging/protective film is used to prevent scratches during shipping and installation?

Final Thought: Buy the "Surface Outcome," Not the Sheet

Powder painted color coated aluminum sheet is best purchased like you'd buy a finished panel: appearance, durability, and fabrication success come first. When those are clearly defined, alloy and thickness become straightforward supporting choices-not guesses.

https://www.aluminumplate.net/a/powder-painted-color-coated-aluminum-sheet.html