1100 Aluminum Coil Of Mirror Finish

1100 Aluminum Coil of Mirror Finish: A Shimmering Innovation in Aluminum Products

In the vast landscape of industrial materials, the 1100 aluminum coil with a mirror finish stands out, not just for its aesthetic appeal but also for its remarkable versatility and technical attributes.

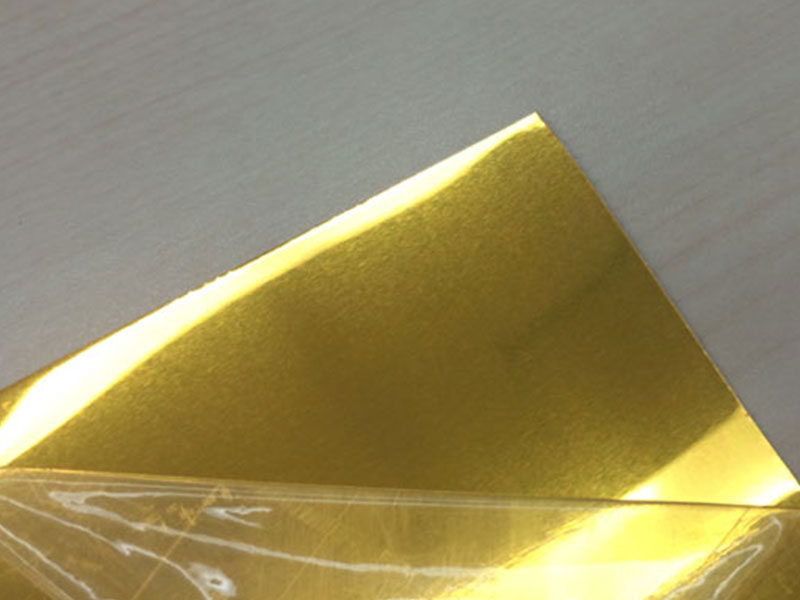

Working with 1100 aluminum coil in its mirror finish presents unique challenges compared to other aluminum alloys. The incredibly high reflectivity demands meticulous handling throughout the entire production process. Even minor scratches or blemishes become glaringly obvious, requiring stringent quality control at every stage, from the initial rolling to the final packaging. This means we're constantly refining our techniques—experimenting with different polishing compounds, adjusting roller pressures, and meticulously cleaning the equipment to prevent even microscopic imperfections. The delicate nature of the finish also impacts our inventory management; storing these coils requires specialized racking and protective coverings to prevent damage from abrasion or environmental factors. It's a fascinating material, but demands the utmost care and precision.

Personally, I find the transformation of a raw aluminum coil into a gleaming, mirror-like surface incredibly satisfying. The process itself is a testament to human ingenuity and the precision of our machinery. Seeing the final product, reflecting a near-perfect image, is a constant source of professional pride. However, the pressure is always on; a single flaw can ruin a whole coil, leading to significant material waste and lost revenue. It's a delicate balance between pushing the boundaries of what's achievable in terms of reflectivity and maintaining the necessary efficiency for large-scale production. This constant tension fuels a relentless pursuit of perfection within our team.

1100 Aluminum Coil

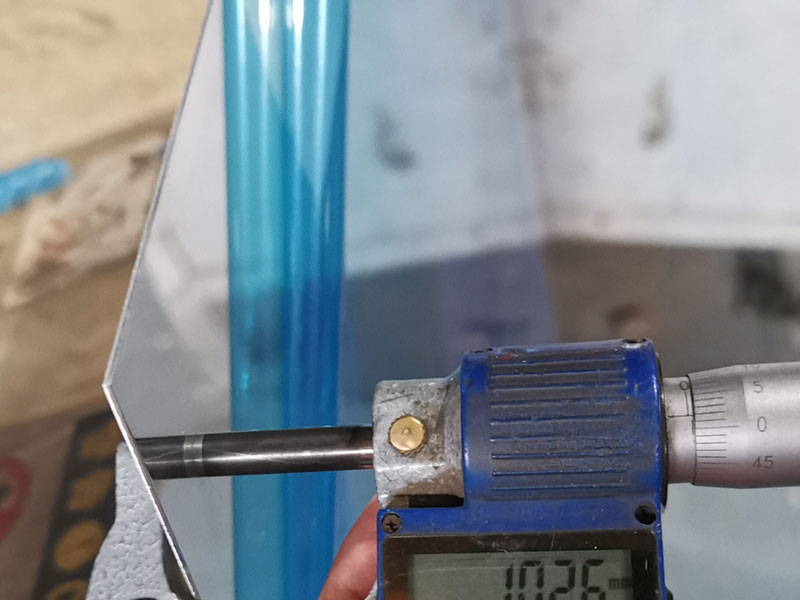

The designation, “1100,” refers to aluminum that is composed of at least 99.0% pure aluminum. This high level of purity translates to excellent corrosion resistance, conductivity, and formability, making it a fitting choice for various applications. When it comes to the coil structure, it epitomizes convenience, often embodying long sheets of aluminum that can be easily cut, shaped, and rolled to desired dimensions.

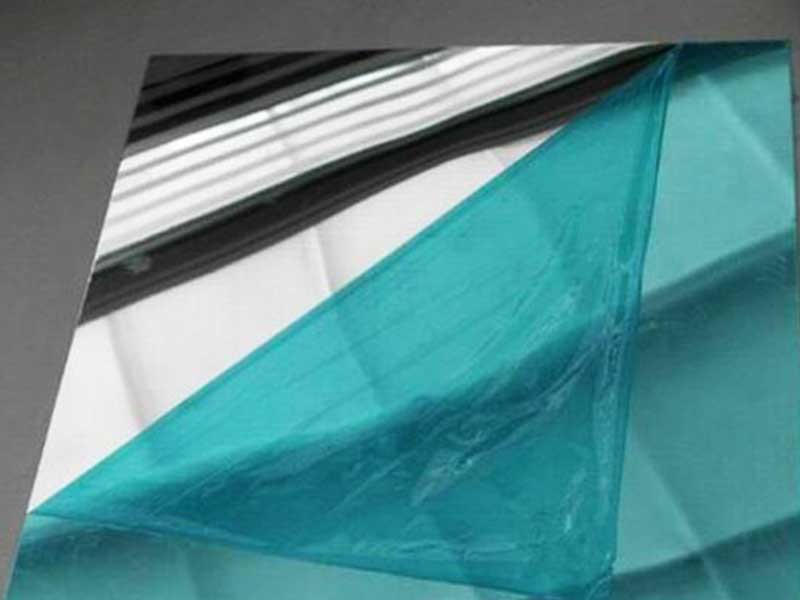

The Mirror Finish: Beauty Meets Functionality

What truly differentiates the 1100 aluminum coil from others is its lustrous mirror finish. This reflective surface not only elevates its visual appeal but also enhances its utility in several sectors:

-

Reflective Component: The mirror finish provides not just an aesthetic upgrade but also functional benefits in areas like reflectivity. This attribute makes it an ideal candidate for applications in lighting fixtures, where increased light reflection persists the overall luminance while optimizing energy consumption.

-

Surface Durability: Despite its shiny exterior, the 1100 aluminum coil’s surface is marked by significant durability, helping to withstand environmental factors. This quality is particularly useful in architectural applications that require both style and resilience.

-

Lightweight Nature: The inherent lightweight composition of the 1100 coil supports high maneuverability and installation flexibility. It allows various configurations, making it a go-to option for sectors that prioritize weight efficiency—such as the aerospace industry.

Applications of 1100 Aluminum Coil with Mirror Finish

The applications of 1100 aluminum coil with a mirror finish are nearly limitless, integrating seamlessly into numerous projects worldwide. Here are some standout applications:

-

Architectural Design: The premium aesthetic characteristics of mirror-finish aluminum coil have made it an attractive choice for exterior and interior architecture. From skyscrapers housing reflective facades to elegant interior design elements, the visual impact is often striking.

-

Cooking and Kitchen Utensils: Due to their superior thermal properties and resistance to various environmental factors, 1100 aluminum coils are commonly found in culinary tools, such as cooker stovetops and bakeware. The reflective surface can elevate design while ensuring durability.

-

Electrical Components: The excellent electrical conductivity associated with 1100 aluminum guarantees reliability in devices where heat dissipation is paramount. This characteristic reinforces its integral role in components used in LED lighting systems and various electrical applications.

-

Signs and Displays: The eye-catching quality of the mirror finish contributes decisively to signage and display units. Whether used for retail showcases that elevate product presentation or as decorative signage in event spaces, these aluminum coils ensure a memorable visual statement.

https://www.aluminumplate.net/a/1100-aluminum-coil-of-mirror-finish.html