Aluminum sheet 0.7mm Thick 3003 H18 Color Coated

When it comes to aluminum sheet products, the 0.7mm thick 3003 H18 color-coated variant is a hidden gem that combines robustness with aesthetic versatility. As the landscape of materials science evolves, the incorporation of aluminum into various industries continues to expand.

Technical Overview: Strength in Every Micron

The 3003 alloy, known for its excellent workability, corrosion resistance, and formability, becomes even more with the H18 temper, which indicates an additional hardness achieved through cold working. The 0.7mm thickness emphasizes the sheet’s lightweight nature without compromising its strength—critical in industries where lower material weight enhances performance.

Amid much attention given to technical specifications like thickness and temper, the critical aspect of a color-coated aluminum sheet lies within its surface treatment. The color coating extends beyond aesthetic appeal; it significantly improves resistance to weathering and chemical abrasion, ensuring longevity despite exposure to outside elements. Coatings can also fulfill specific regulatory standards for aesthetics and performance, ensuring usability across various environments.

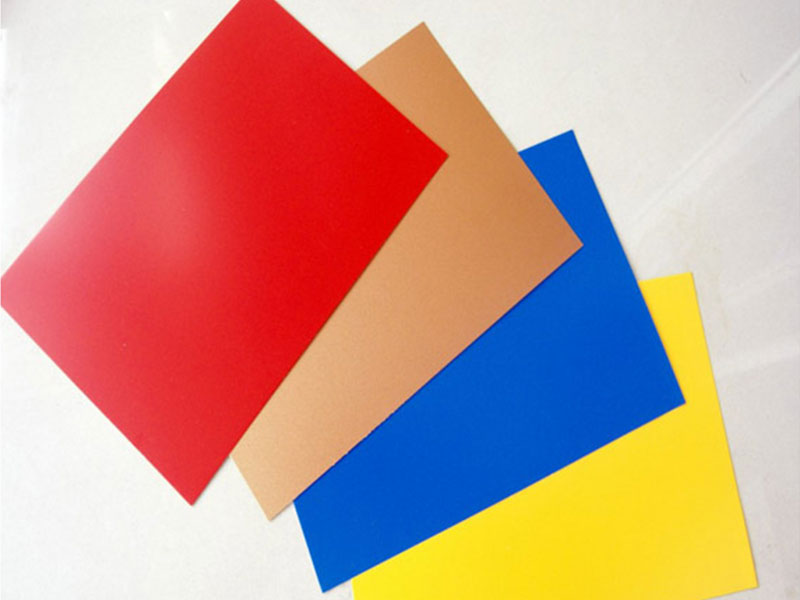

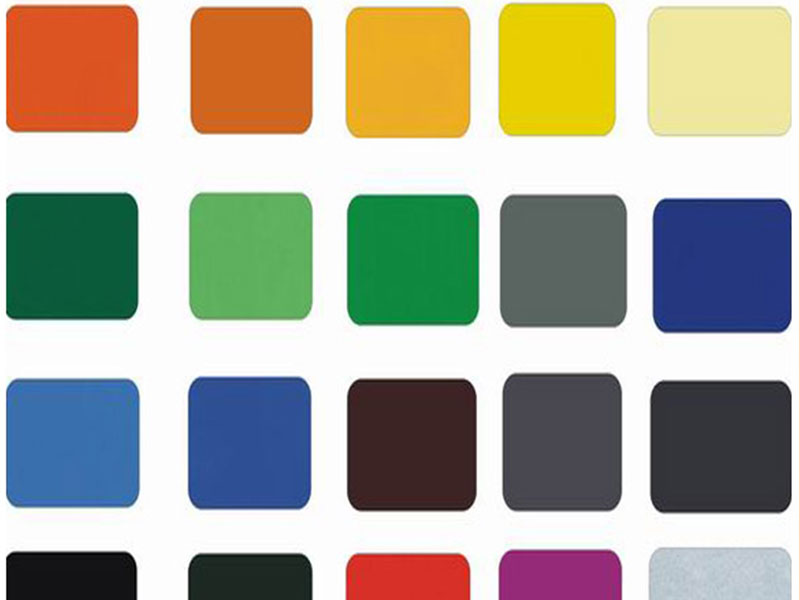

Aesthetic versus Utility: The Art of Color Coating

Color coating adds a layer of distinctiveness that prides its adoption in designer applications. Available in a plethora of colors – wealth of options ensures compatibility with brand identities while offering an upscale look. Not only does this enhance visual appeal, but the coating can also include special properties like anti-fingerprint and coatings designed for UV resistance. Many modern eco-system solutions involve structures emphasizing atmospheric aesthetics, and coated aluminum sheets help fulfill these needs.

Diverse Applications: Expedited Versatility Across Sectors

The versatility of the 0.7mm thick 3003 H18 color-coated aluminum sheet allows for an array of applications across different sectors:

-

Architectural Elements: In architectural designs, this aluminum sheet can be utilized for wall cladding and canopy structures, meeting precision industrial designs while also benefiting architects intending to create long-lasting buildings with visuals that catch the eye.

-

Interior Décor: The striking features of color coatings allow homeowners and interior designers to use the sheet in decorative panels, room partitions, or furniture fronts. Unique finishing relays unlimited potential combinations of function and style.

-

Fridge and HVAC Casings: The excellent light weight and corrosion resistance make it suitable for manufacturing housings that require reliability without burdensome weight, perfect for refrigerating and heating units where space and airflow must be implemented correctly.

-

Signage: Engaging storefront signs and banners crafted from this material can feature vivid colors to attract onlookers while supporting rugged outdoor endurance.

-

Transport Industry: Applications in the transport industry lend themselves to aluminum sheet's reduced weight aiding in energy efficiency and enhanced load-bearing capacities molded into vehicle trailers, utility platforms, and more.

Eco-Friendly Component: Sustainability in Coating Choices

In today’s context of sustainability, utilizing 3003 H18 aluminum additionally resonates with environmental consciousness. Specifically leading manufacturers continue investigating improvements in both coatings and recycling processes, encouraging sustainable construction practices while ensuring quality in building materials spans multiple sector applications.

The future of building and infrastructure push enterprises towards solutions synergizing aesthetics, adaptability, performance metrics, and environmental sustainability—weaving future-focused strategies into architectural endeavors wherein the aluminum sheets shine provisionary as innovative, eco-friendly building blocks.

https://www.aluminumplate.net/a/aluminum-sheet-07mm-thick-3003-h18-color-coated.html