CTP plate offset ctp printing plates

In the evolving technology landscape, creatives and businesses constantly seek ways to enhance production efficiency and print quality. One significant innovation in the realm of printing is Computer-to-Plate (CTP) technology, a method that deals fundamentally with offset printing plates.

What Are CTP Plates?

At its core, Computer-to-Plate (CTP) technology serves to directly transfer digital images onto printing plates, eliminating many of the older analog processes traditionally used in print preparation. In offset printing, this translates into a more streamlined workflow that begins and ends with your digital files. Rather than creating a physical film that subsequently moves the desired image onto the plate, CTP allows printers to cater directly to digital files, saving both time and resources.

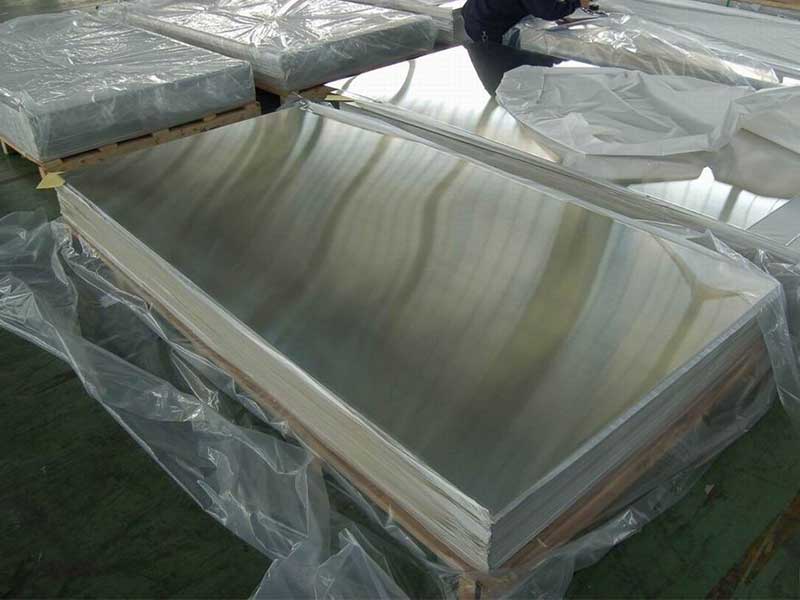

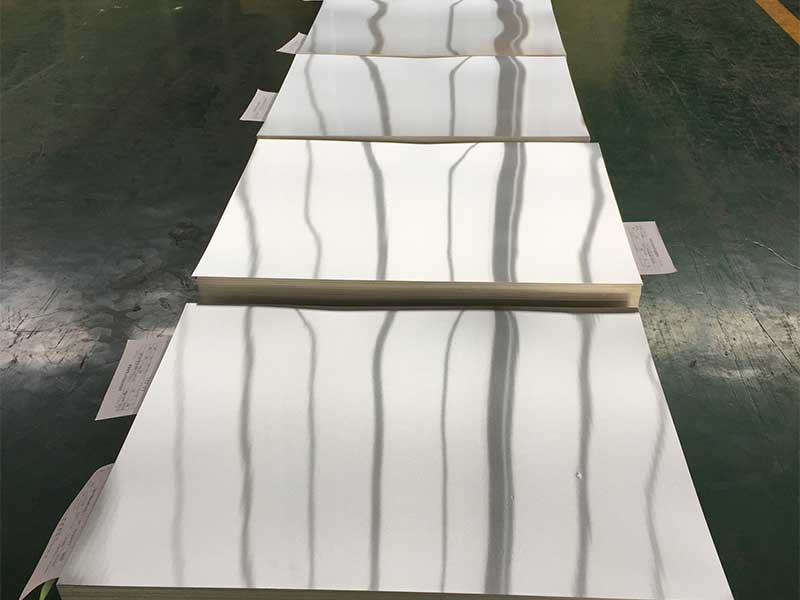

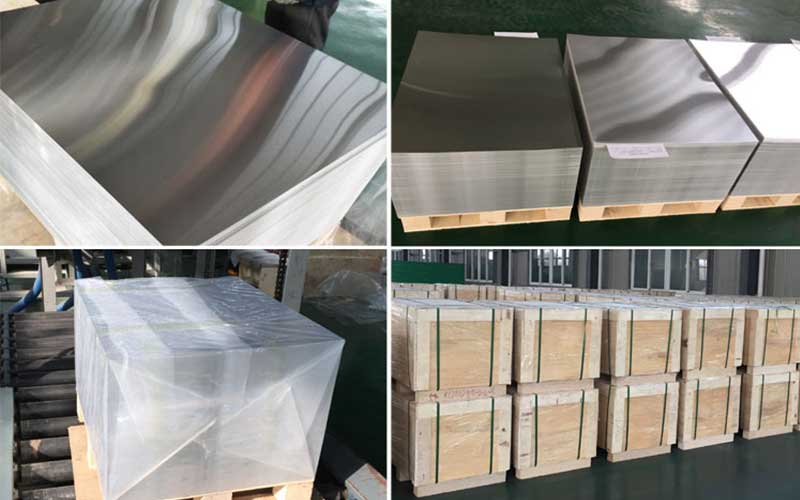

While there are various types of printing plates, from polyester to hybrid options, aluminum CTP plates are regaining stark prominence. These plates enhance image sharpness and clarity, contributing not just to aesthetics but also to accuracy and efficiency throughout the printing process.

The Manufacturing Making: Behind the Scenes

Let’s pause and reflect on what happens behind the curtain during the development of these aluminium CTP plates. The high-quality aluminium used is usually anodized, creating a thin layer of oxidation that complements the plates’ printing characteristics. This surface plays two roles: it presents a superior affinity for ink while rendering a repellant loyalty to the non-image areas, which then reject ink during the transfer process. The result? Higher fidelity prints with great clarity—a visionary's utopia halfway between the digital blueprint and tangible art.

Efficiency Meets Quality

One of the most outstanding advantages of employing aluminium CTP plates arises in the quality and consistency it delivers. With traditional film plates, the iterative cycle of proofing, approval, and plate preparation consumed abundant time that modern businesses can ill afford. CTP technology digitalizes this rasterizing process, ensuring that not only can printers prepare batches far quicker but each individual plate produced carries uniform quality across the lot. A milestone in the race for pristine and dependable output.

Moreover, it presents a greener alternative to printing. The refined manufacturing properties of aluminium lessen waste produced from conventional methods, revealing yet another benefit of innovation: environmental sustainability. A reminder that efficient shouldn't compromise the planet, even in industries so reliant on resource deployment.

Challenges: Overcoming Misconceptions

Conversely, the CTP plate method isn’t without its challenges. One common misconception trickled throughout the community stems from initial set-up costs; they seem prohibitive to some smaller print shops. However, when evaluated over time concerning speed, reducing Make Ready Time, and cost-effectiveness on material fronts, investing in aluminium CTP plates far outweighs traditional production methods long term.

On top of that, while transitioning from film can proffer relief, it may require some pivotal retraining. Navigating expertly between digital printing binds times triumph with the treasures some veterans constructed through conventional methods over years—even decades. Yet that doesn’t detract from the benefits of a couple of well-placed hours in training, creating record-break réal resync enlightenment between authors and readers saved tangentionally into print across enthusiastic shelves alike.

https://www.aluminumplate.net/a/ctp-plate-offset-ctp-printing-plates.html