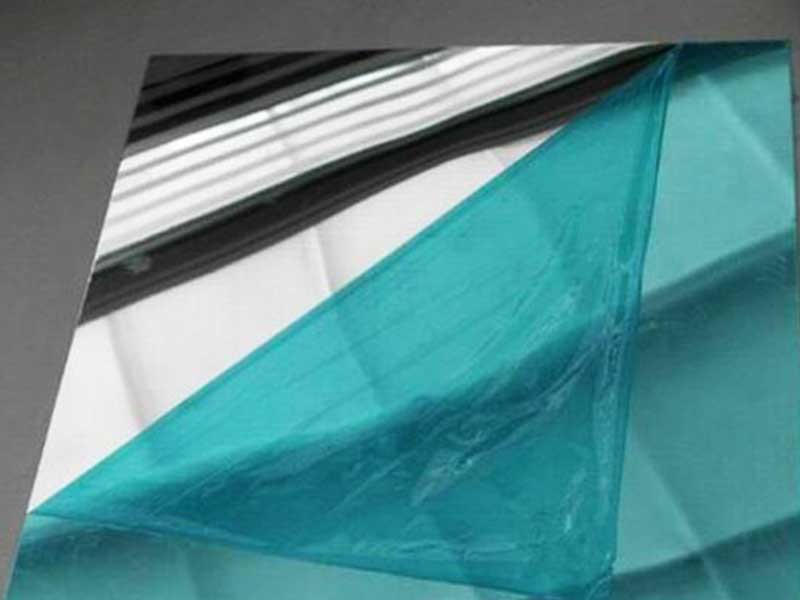

Mirror Finish Coated Aluminum Coil

In recent years, mirror finish coated aluminum coils have become increasingly popular across various industries for their impressive aesthetic appeal and functional properties. These innovative materials are designed to meet the evolving needs of contemporary design and manufacturing, making them an excellent choice for architects, designers, and engineers alike.

Exceptional Features of Mirror Finish Coated Aluminum Coils

-

Highly Reflective Surface: The standout feature of mirror finish coated aluminum coils is their reflective quality. The smooth, polished surface creates a stunning mirror effect, making it a favored choice for applications where beauty and light reflection are paramount.

-

Corrosion Resistance: The coating process not only enhances the visual appeal but also provides an additional layer of protection against environmental factors. This makes mirror finish coated aluminum coils highly resistant to rust and corrosion, ensuring longevity in various conditions.

-

Lightweight and Durable: Aluminum is well-regarded for its lightweight nature. When combined with a protective finish, mirror aluminum coils retain their lightweight attributes while providing superior strength. This characteristic is particularly valuable in construction and automotive applications.

-

Versatile Coating Options: The surface of these coils can be custom coated in various colors or textures, adding to their versatility. This feature enables architects and designers to match their specific aesthetic requirements, allowing for creative freedom in projects.

-

Ease of Fabrication: Mirror finish coated aluminum coils are easy to fabricate, which facilitates quick and efficient production. This makes them an ideal material for manufacturers looking to streamline operations without sacrificing quality.

Applications of Mirror Finish Coated Aluminum Coils

Mirror finish coated aluminum coils find utility in a myriad of applications across several industries:

-

Architectural Design: One of the most prominent applications is in architectural facades, ensuring that buildings not only draw attention but also seamlessly integrate into their surroundings by reflecting light and nature. This makes them popular in both commercial and residential sectors.

-

Interior Decor: Designers use mirror finish coated aluminum for interior elements like ceiling panels, wall cladding, and decorative fixtures. The reflection enhances interior spaces, making them appear larger and more sophisticated.

-

Signage and Advertising: With their brilliant shine, these coils are popular for creating eye-catching signs and advertising displays. The reflective quality of mirror finish coatings not only attracts attention but also conveys quality and luxury.

-

Automotive Industry: In the automotive sector, mirror finish coated aluminum is utilized for parts like trim and accents. Its durability ensures that the gleaming finish endures in outdoor conditions while enhancing the vehicle's aesthetic appeal.

-

Consumer Electronics: Many high-end electronics feature mirror finish coatings, as they convey a sense of premium quality. Laptops, speakers, and smartphones often utilize this reflective material for their exteriors.

-

Aerospace Components: Given its remarkable strength-to-weight ratio and thermal conductivity, mirror finish coated aluminum is also used in select aerospace applications, helping to enhance performance while reducing overall weight.

https://www.aluminumplate.net/a/mirror-finish-coated-aluminum-coil.html