Photographic UV CTP CTcP plate with Developer

In the printing world, advancements in technology continue to push the boundaries of quality and efficiency. One significant development in this domain is the use of Photographic UV CTP (Computer-to-Plate) and CTvP (Computer-to-Plate) plates combined with specialized developer solutions. These innovations not only enhance print quality but also streamline the production process for commercial printers.

Understanding the Technology: Photographic UV CTP & CTcP Plates

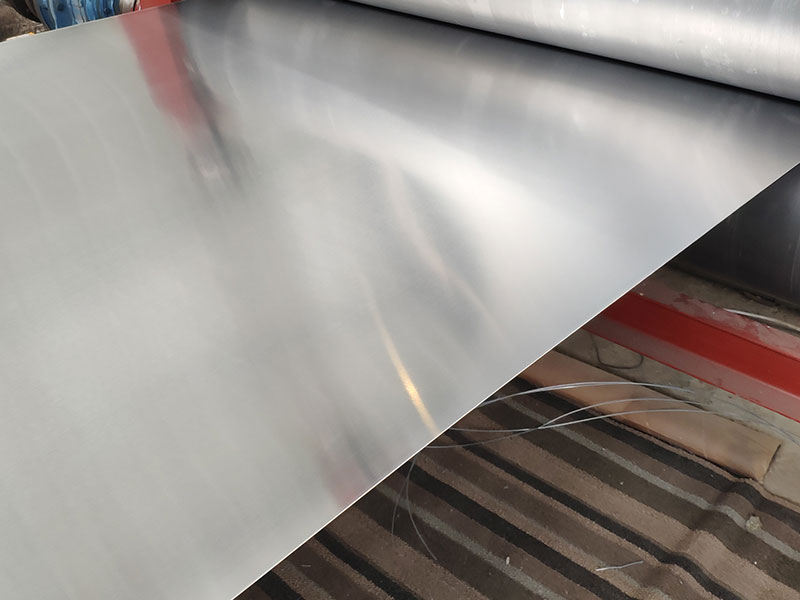

Photographic UV CTP plates are made of high-quality aluminum alloy and are engineered to respond to UV light exposure, allowing for exceptional image clarity and detail. They are designed specifically for high-end printing, providing superior resolution and tonal range compared to standard alternatives. The use of UV technology ensures that the plates are not only durable but also capable of delivering sharper and cleaner images.

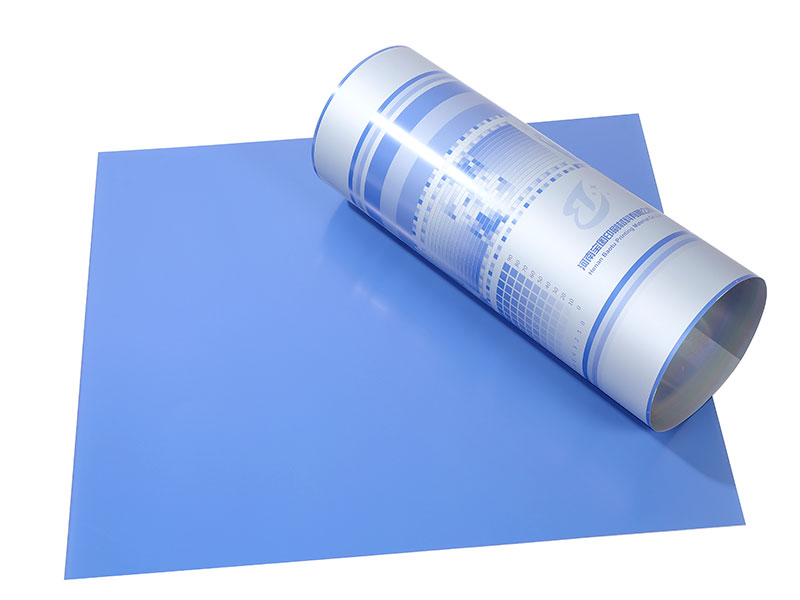

On the other hand, CTcP plates—standing for Computer-to-Color Plate—use a different technological approach, allowing for ease of imaging and the generation of fine details in color. This makes them ideal for the printing of high-resolution images and complicated designs, which are often essential for advertising or marketing materials.

Benefits of Using Developer Solutions

To realize the full potential of photographic UV CTP and CTcP plates, the use of developer solutions becomes crucial. These solutions are formulated to work in coordination with the plates, effectively washing away unexposed areas while strengthening the imaged sections, thus enhancing the plate’s reliability.

-

Enhanced Print Quality: Using a developer with your photographic UV CTP and CTcP plates ensures that images are processed cleanly. This, in turn, leads to higher print quality with more defined graphics, aiding in reproducing vibrant colors and intricate designs.

-

Prolonged Plate Longevity: Advanced developer solutions help prolong the lifetime of CTP plates by preventing oxidation and wear. This translates to fewer replacements and less downtime, resulting in greater operational efficiency.

-

Faster Processing Times: The result of a well-formulated developer is a reduction in time spent in plate preparation. With optimized processing speeds, printers can accelerate their workflows without compromising on quality.

-

Environmental Considerations: Modern developers are often created with eco-friendliness in mind, reducing water usage and chemical waste, making them a more sustainable choice for printers looking to less their environmental footprint.

How to Achieve the Best Results

Using photographic UV CTP and CTcP plates effectively requires consideration of a few critical factors:

- Plate Exposure: Proper setting during exposure is necessary to ensure that the plates receive the optimal amount of UV light for ideal performance.

- Development Time: Following the manufacturer's guidelines for development time will ensure both the quality of the final print and the longevity of the plates.

- Quality Control: Employing stringent quality control measures during the preparation and printing processes will maximize the advantages offered by these aluminum alloy technologies.

https://www.aluminumplate.net/a/photographic-uv-ctp-ctcp-plate-with-developer.html