Printing plate CTP plate

The printing industry has witnessed a paradigm shift from analog processes to digital advancements, paving the way for innovative solutions that boost productivity and precision. Among these breakthroughs, the Computer-to-Plate (CTP) technology stands out significantly. By seamlessly bridging the gap between digital design and the physical printing process, CTP plates impart new possibilities in the world of printing.

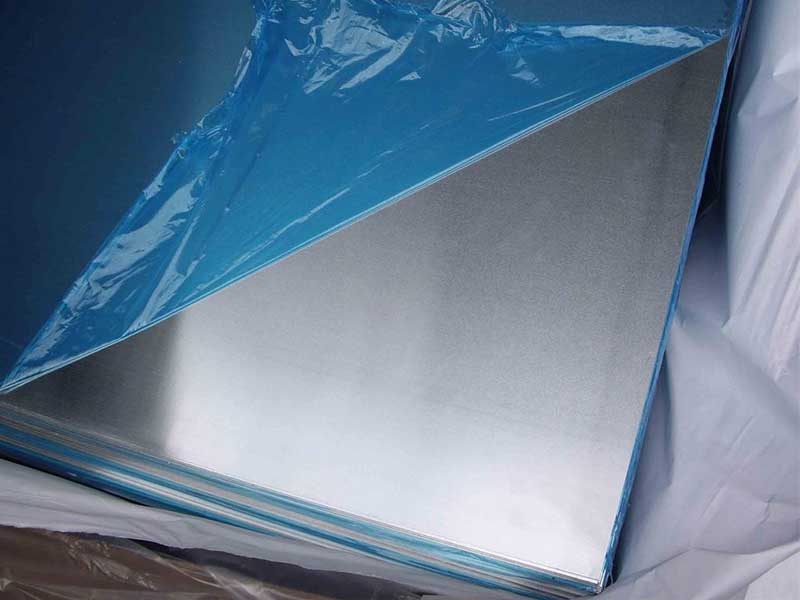

CTP Plates

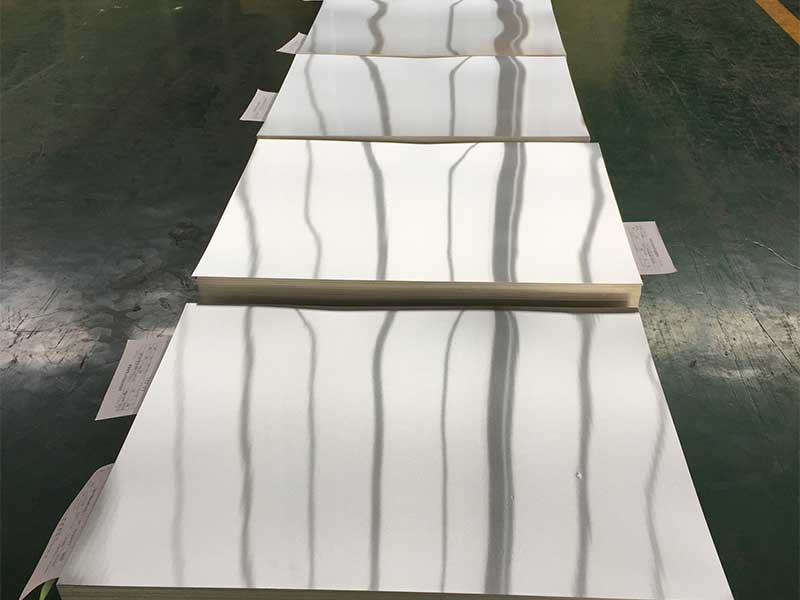

At its core, CTP technology eliminates the need for traditional offset printing processes, which typically involve making film positives before transferring images to plates. By directly exposing printing plates with digital images, CTP plates enhance consistency and minimize manual intervention. This not only streamlines the workflow but also reduces lead times, making CTP plates essential in today’s fast-paced environments.

My experience with aluminum CTP (Computer-to-Plate) plates reveals a fascinating interplay between material science and printing precision. We constantly refine our processes to achieve optimal plate quality, focusing on factors often overlooked by those outside the industry. For instance, the subtle variations in aluminum alloy composition significantly impact the plate's ability to accept and retain the imaged layer. A seemingly minor change in alloying elements can dramatically affect the plate's longevity, its resistance to scratching and abrasion during printing, and ultimately, the consistency of the final print. Furthermore, the precise control of the imaging process – the laser power, exposure time, and development chemistry – is critical. Even seemingly insignificant fluctuations can lead to variations in dot gain and print density, affecting image reproduction quality and requiring costly adjustments.

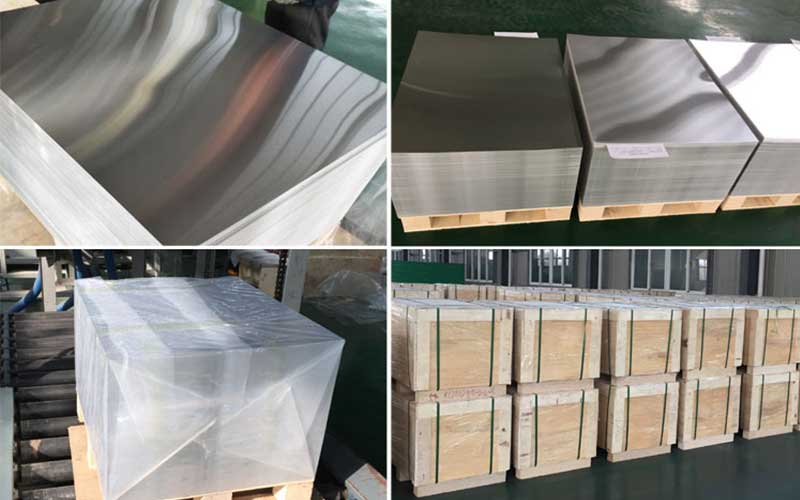

Beyond the technical specifications, the relationship between the CTP plate and the overall printing press is crucial. A plate perfectly imaged and processed might still yield subpar results if the press is not properly calibrated or maintained. Issues such as improper ink-water balance or inconsistent blanket pressure can mask even the most flawlessly produced CTP plate, resulting in print defects that are wrongly attributed to the plate itself. Consequently, a truly effective technician must possess a holistic of the entire printing workflow, from plate creation to final output, allowing for efficient troubleshooting and proactive prevention of recurring issues. This system-wide perspective is essential for maximizing the lifespan and performance of our aluminum CTP plates and ensuring consistently high-

Major Functions of CTP Plates

-

Direct Imaging for Greater Precision CTP technology employs laser exposure methods which enable incredible precision in transferring digital designs onto the plate surface. Unlike conventional plates that may distort images through processes like film exposure, CTP plates guarantee sharp, high-resolution reproductions critical for detailed prints, such as photographic reproductions or intricate graphics.

-

Reduced Production Costs In modern commercial printing environments, reducing costs while maximizing production remains a top priority. CTP plates facilitate these objectives by negating film processing and eliminating the need for extensive setup time. With materials that require fewer consumables and generate less waste, CTP plates present a cost-effective solution for small to large print runs.

-

Color Consistency and Quality Control The digital nature of CTP plates allows for greater control over the color management process. Printers can easily calibrate colors digitally, ensuring that the final output matches the intended design flawlessly. This capability fosters a reputation for quality, making CTP plates a preferred choice for businesses aiming to uphold brand integrity.

-

Enhanced Durability and Longevity Modern Aluminium CTP plates have the added advantage of exceptional durability. Their resistance to wear and tear prevents degradation during prolonged production runs, ensuring architects, magazine publishers, and packaging companies can print larger volumes without sacrificing the quality of images over time.

Applications of CTP Plates

-

Commercial Printing From catalogs and brochures to large posters, commercial printing companies leverage CTP plates to achieve sharp text and vibrant imagery. Their rapid setup capabilities enable short runs for bespoke projects while still preserving high print quality.

-

Packaging The customizable nature of CTP plates makes them an ideal fit in the packaging sector. The flexibility allows manufacturers to cater to different shapes and sizes, meeting the unique demands of product branding.

-

Publishing In book and magazine publishing, where timeliness is often tied to sales success, CTP technology's ability to significantly shorten preparation times can enhance competitive edge. Additionally, the print quality remains exceptional.

A Future-Forward Perspective

As we navigate toward increasingly digital practices in manufacturing and creative sectors, CTP plates exemplify how technology can transform industry standards while offering significant advantages in terms of efficiency and output quality. Adopting CTP technology signifies not only a commitment to innovation but also an embrace of sustainable practices by significantly lowering material waste and fostering precise production processes.

Given their versatility and range of applications, printing plates, especially Aluminium CTP plates, have solidified themselves as integral players in the evolving printing landscape. Embracing this advancement is more than just a technological leap; it's a strategic move imperative for businesses looking to thrive in the competitive printing market.

By fully grasping the unique aspects of CTP plates—ranging from their technical nuances to their expansive applications—we can better appreciate their role in shaping the future of printing. Whether you are in commercial, packaging, or publishing sectors, CTP plates offer intelligent solutions uniquely tailored for a variety of demands.

https://www.aluminumplate.net/a/printing-plate-ctp-plate.html