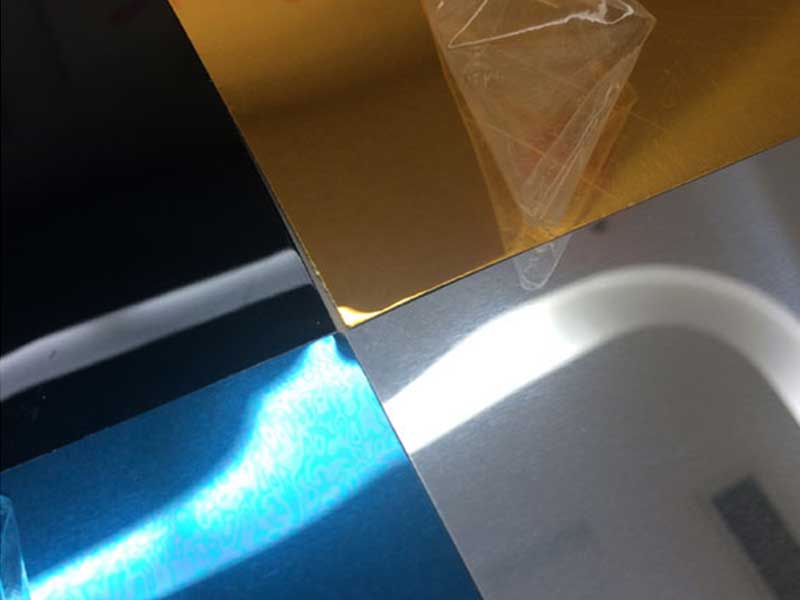

1060 1070 1080 1085 1090 aluminum mirror sheet and coils

Reflecting the Future: A Distinctive Insight into 1060, 1070, 1080, 1085, and 1090 Aluminum Mirror Sheets and Coils

When we think about aluminum mirror sheets and coils, the mind drifts to glinting surfaces that catch sunlight or the glimmer of city lights bouncing off towering skyscrapers. However, beneath that shiny veneer lies a world of technical distinction that can guide industries in choosing the right material for their specific needs. Today, we’ll explore the variations among the 1060, 1070, 1080, 1085, and 1090 grades of aluminum - each a masterpiece in its own right.

Working with 1060, 1070, 1080, 1085, and 1090 aluminum mirror sheets and coils reveals a fascinating interplay between alloy composition and final product quality. The subtle differences in manganese content across these alloys directly impact their workability and the final reflectivity. For instance, the higher manganese content in 1070 compared to 1060 offers slightly improved strength, crucial for larger sheets or coils that need to withstand handling and transport. However, this can sometimes lead to slightly more challenging polishing, requiring adjustments to our surface finishing processes to achieve the same mirror-like finish. We've found that optimizing the annealing process is vital for each alloy, ensuring the right balance between softness for forming and retaining the flatness crucial for achieving a flawless reflection. Inconsistencies in the raw material's grain structure can also affect the final product, so rigorous incoming quality checks are essential.

the specific applications for each alloy is to efficient production. 1060, with its superior corrosion resistance and excellent reflectivity, is often preferred for applications requiring high aesthetic appeal, such as architectural cladding or decorative panels. Conversely, the slightly higher strength of alloys like 1085 might be better suited for more demanding industrial applications where minor scratching or denting is more likely. We've seen instances where clients initially specify a certain alloy without fully its nuances,

The Reflections of Variety

In the shimmering landscape of aluminum sheets, the old adage “quality over quantity” is exemplified in these different grades. The differences lie predominantly in their chemical compositions, and their specific attributes translate to specific uses. Each number unlocks a specific history of experience in the manufacturing of high-quality aluminum materials where durability, degree of etched flatness, and application composite clarify their purpose:

-

1060 Aluminum Mirror Sheet: This grade contains at least 99.6% aluminum, making it highly resistant to corrosion while promoting excellent reflectivity. Commonly used in decorative applications, lighting fixtures, and the construction of environments that necessitate brightness, 1060 is the versatile base for many industries, encouraging beautifully illuminated spaces.

-

1070 Aluminum Mirror Sheet: Aligning closely with 1060 yet boasting slightly enhanced mechanical properties, 1070 features minimum aluminum content that's generally 99.7%-99.9%. This pairing allows for greater sound and heat insulation compared to its 1060 counterpart. The 1070 grade is increasingly favored in high-end projects, such as architecture & building, where strength coupled with aesthetics can sparkle.

-

1085 Aluminum Mirror Sheet: Offering immense versatility, 1085 overlap takes part in the sound reflectivity and echo product guidelines pivotal in auditory equipment and architecture. These sheets radiate quality stage performances while cutting down on noisy interruptive elements that undermine compelling productions. Its cottoned design transcends fields, satisfying those upper-tier intricacies ideally.

-

1090 Aluminum Mirror Sheet: Capstone grade – that’s the only way to describe the graphs etched around 1090. Proudly meant for dazzlingly specialty industries employing reflective bespoke solutions for significant exclusive markets, this mirrors choices intended for visionary dazzling scenarios. This weightless social material leads photography and customized artworks into poetic realms that remain lodged in people's memories.

Practical Applications: More Than Just Looks

Although their reflective qualities bring visual delight, each grade goes beyond aesthetics by encapsulating robust utility across various real-world applications:

- Traffic control devices leverage high reflectivity to ensure visibility while enhancing the user experience.

- Food-grade packaging, where hygiene contributes significantly to product stability and definition, embraces technologically advanced reflective aluminum sheets.

- Thermal shielding translates through mirror UV protection, supporting efficient internal temperature maintenance through UV reflection mechanisms in electronic devices.

https://www.aluminumplate.net/a/1060-1070-1080-1085-1090-aluminum-mirror-sheet-and-coils.html