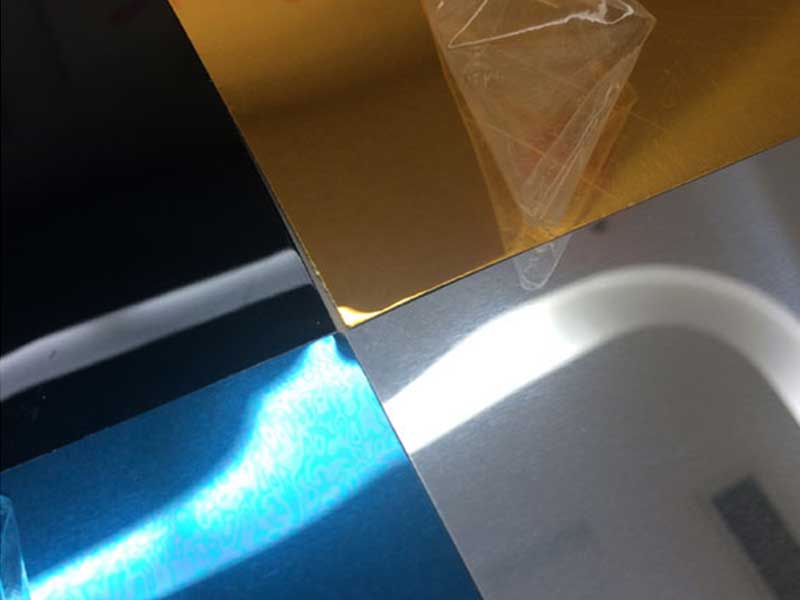

1050 1060 1100 Mirror Finish Polished Aluminum Coil

The 1050, 1060, and 1100 Mirror Finish Polished Aluminum Coils represent some of the highest quality aluminum products available for industries requiring a blend of superior surface finish, excellent corrosion resistance, and outstanding workability. These coils combine the intrinsic chemical purity of commercially pure aluminum alloys with a precision mirror polishing process to achieve a highly reflective surface. Widely used in architectural, decorative, and industrial applications, these polished aluminum coils suit projects where both aesthetic appeal and functional material performance matter.

These three alloys fall under the category of commercial purity aluminum, generally greater than 99% by weight aluminum with just minimal alloying additions.

| Property | 1050 Alloy | 1060 Alloy | 1100 Alloy |

|---|---|---|---|

| Aluminum Content (%) | 99.5 | 99.6 | 99.0 |

| Main Impurities (%) | Fe + Si < 0.40 | Fe + Si < 0.40 | Cu ≤ 0.05, Fe + Si < 0.95 |

| Density (g/cm³) | 2.71 | 2.71 | 2.71 |

| Tensile Strength (MPa) | 70–105 | 65–110 | 90–130 |

| Yield Strength (MPa) | 35–45 | 35–50 | 20–40 |

| Electric Conductivity (% IACS) | 61–64 | 60–64 | 59–63 |

| Thermal Conductivity (W/m·K) | 220 | 220 | 222 |

| Corrosion Resistance | Excellent | Excellent | Excellent |

| Workability | Excellent | Excellent | Excellent |

Note:

- IACS = International Annealed Copper Standard, a measure of electrical conductivity.

- All values depend on temper and exact formulation.

Features of Mirror Finish Polished Aluminum Coils

1. Superior Surface Finish

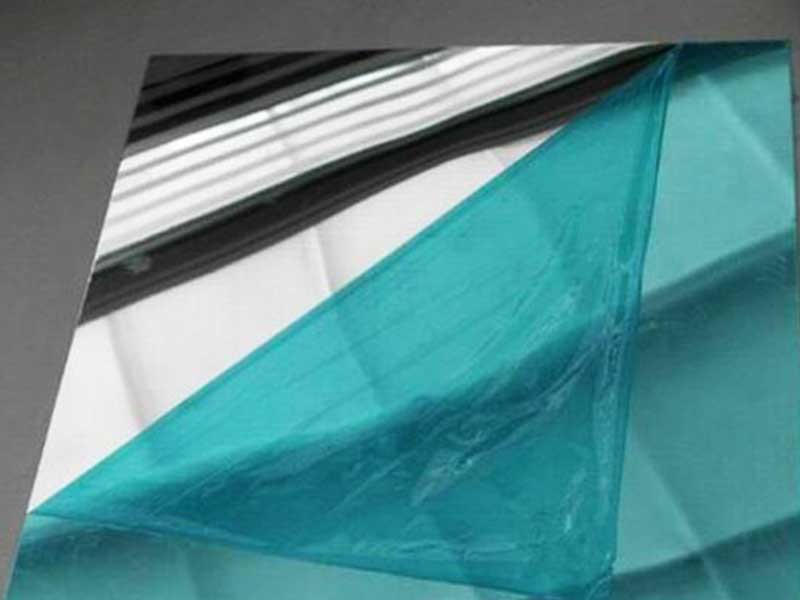

- The defining feature is the high-gloss mirror finish achieved via multi-stage mechanical polishing and careful rolling and finishing processes.

- No surface blemishes, stains, or regular mill finish irregularities appear, ultimately creating a visually striking reflective surface, close to that of a mirror.

- Thickness uniformity and flatness are enhanced in polishing, providing an aesthetic and premium-grade material.

2. Excellent Corrosion Resistance

- Commercially pure aluminum alloys are naturally resistant to oxidation due to the formation of a protective oxide film.

- Mirror-polished surface further enhances resistance by reducing surface roughness where corrosive elements might otherwise accumulate or initiate oxidation.

3. Outstanding Workability

- These alloys possess excellent cold workability and can be readily cut, bent, stamped, or roll-formed.

- Mirror finish is retained with proper handling—important for fabricators aiming for an end-product that continues to boast surface brilliance.

4. Good Thermal and Electrical Conductivity

- Useful in applications demanding efficient heat and electrical conduction.

- Polished surface minimizes surface mercury and particulate contact points, beneficial in electrical and thermal management.

5. Lightweight and Durable

- Aluminum’s high strength-to-weight ratio aids design flexibility, particularly for lightweight decorative panels.

Typical Specifications

| Parameter | Range / Standard Values |

|---|---|

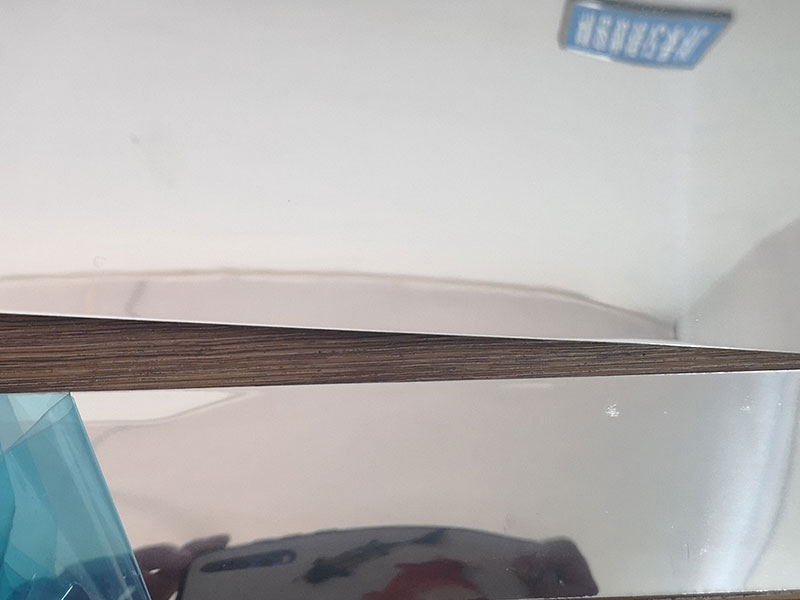

| Thickness (mm) | 0.2 to 3.0 |

| Width (mm) | 500 to 1600 |

| Temper | H14, H18, O (annealed), custom tempers available |

| Coil Weight (kg) | 1,000 to 8,000 (main coil weights depending on spec) |

| Surface Finish | Mirror polished; Ra (roughness) < 0.2 μm |

| Packaging | Protective plastic film inside/outside; wooden crates |

| Delivery Condition | Clean with no oil or residues |

Applications

Because of a unique combination of aesthetic requirements and functional benefits, 1050 1060 1100 Mirror Finish Polished Aluminum Coils are preferred across many industries and contemplate diverse statuary fabrication needs:

Working with 1050, 1060, and 1100 series mirror finish polished aluminum coils daily gives me a unique appreciation for the subtleties of their properties. While all three are known for their high reflectivity and excellent corrosion resistance, I've found that the 1050, being the purest, offers the brightest and most consistent mirror finish, but can be slightly softer and more prone to scratching during handling and processing. The 1060, with its slightly higher iron content, provides a good balance of reflectivity, strength, and workability – a popular choice for many applications. The 1100 sits somewhere in between, offering a good compromise between reflectivity and formability. these nuanced differences is to optimizing our production process and ensuring customer satisfaction; a seemingly minor variation in alloy composition can significantly impact the final product's appearance and durability.

Beyond the material specifications, my experience has highlighted the importance of the polishing process itself. Achieving that flawless mirror finish requires meticulous control of parameters like grit size, buffing pressure, and the type of polishing compound used. Even seemingly minor fluctuations in these variables can lead to variations in reflectivity and surface smoothness, impacting the final product’s quality and the efficiency of the production line. I’ve spent considerable time tweaking our polishing techniques, experimenting with different methods and materials to consistently achieve the highest standards. It’s fascinating to witness how a seemingly simple sheet of

1. Architectural and Interior Design

- Decorative panels, ceiling and wall claddings suspension systems, elevator interiors, balustrades, and handrails.

- Reflective surfaces create spacious optical effects and a luxurious preference.

- Ideal for covering facades with high corrosion environment demands.

2. Consumer Electronics and Appliances

- Component casings, reflective housings in LED fixtures.

- Widely used where non-magnetic and lightweight yet stylish body cases are key.

3. Food and Pharmaceutical Industry

- Hygiene-critical environments where smooth surfaces prevent microbe accumulation.

- Aluminum is non-toxic and cleaning compatible with standard methods used in these industries.

4. Transportation and Automotive

- Trim panels with distinct aesthetics.

- Heat shields might also use polished fin surfaces for cooling.

5. Signage and Advertising

- Backing blanks for nameplates, signs, digital display cases that command attention due to the diffuse bright surface.

6. Household and Kitchen Products

- Cookware elements, reflecting panels using natural reflective insulation approaches.

Handling and Storage Recommendations

- Keep polished aluminum coils stored in clean, dust-free environment to avoid scratching.

- Packaging polishes multiples breaks deployment risks during transit.

- Avoid stacking coils without proper interlayer materials.

- Moderate handling and processing speeds ensure uniform finish maintenance.

https://www.aluminumplate.net/a/1050-1060-1100-mirror-finish-polished-aluminum-coil.html