CTP Plate Common Brand Positive Offset Plate Developer Offset Printing

In the realm of offset printing, the quality and performance of the printing plate play an instrumental role in determining final image sharpness, print durability, and press uptime. Positive Computer-to-Plate (CTP) plates have established themselves as industry standards, offering superior image resolution, ease of processing, and cost-effective production workflows.

Computer-to-Plate (CTP) technology enables the digital direct imaging of printing plates without requiring film negatives. The traditional photochemical and film-based steps are replaced with fast, realistic laser modulation exposing the plate directly:

- Positive Plates: In positive CTP plates, the laser-exposed regions become soluble and get washed away during development, leaving the image area intact on the plate.

- Common Brands: Fujifilm, Agfa, Kodak (Avanté), Esko, and Mitsubishi are leading brands known for producing high-performance positive CTP plates.

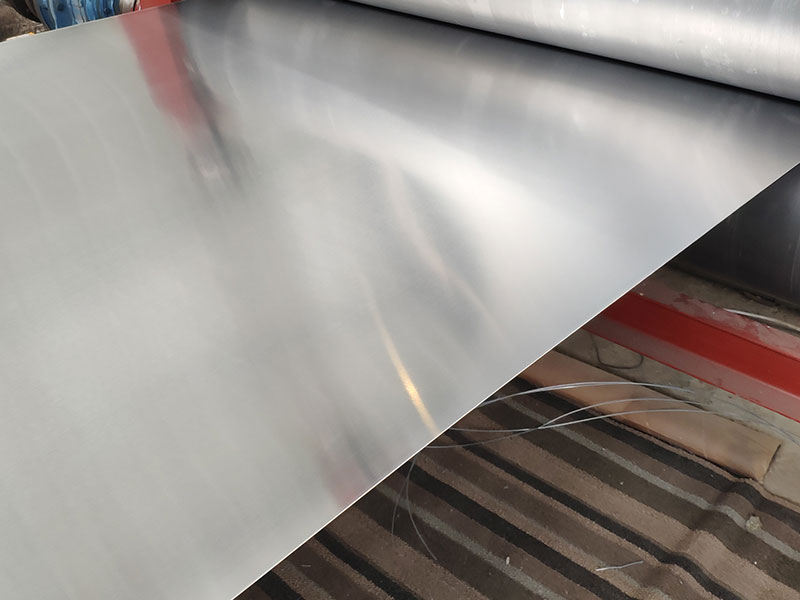

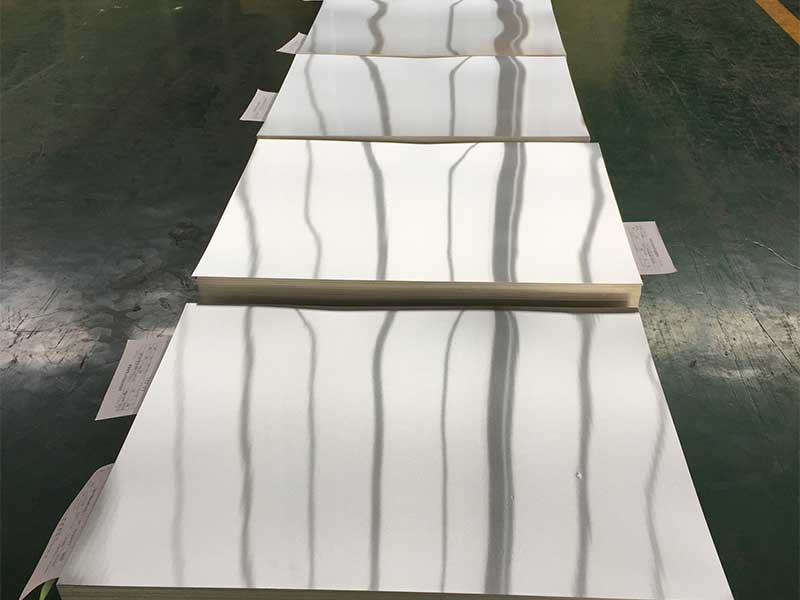

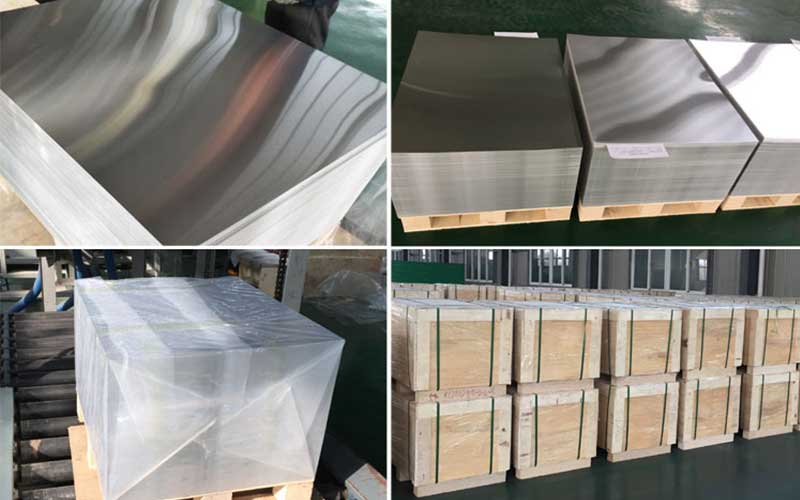

Product Composition and Alloy Tempering of Aluminum CTP Plates

Most offset plates incorporate treated aluminum as the substrate due to its advantageous mechanical and chemical properties.

From a technical standpoint, the performance of our Aluminium CTP plates, particularly regarding developer compatibility, is paramount. We've seen firsthand how different developer chemistries interact with our specific plate formulation. While the manufacturers often provide recommended developers, our in-house testing reveals subtle variations in processing speed, plate life, and ultimately, print quality. For instance, a developer optimized for high-speed processing might compromise the long-term stability of the plate, leading to increased dot gain or unwanted scumming in later runs. Finding the optimal balance between processing efficiency and print longevity remains a constant challenge, requiring careful monitoring and adjustment based on environmental factors like temperature and humidity.

My personal experience highlights the importance of operator training and precise process control. Even with a premium CTP plate and a well-regarded developer, inconsistent development can lead to significant quality issues. Things like developer concentration, bath temperature, and the duration of immersion all directly impact the image quality and the plate's lifespan. We've invested heavily in automated plate processing equipment, but human intervention is still vital for monitoring and maintaining the optimum developer parameters. A skilled technician can readily identify deviations from the ideal process and adjust accordingly, ultimately ensuring consistent and high-quality output of our Aluminium CTP plates for offset printing.

Aluminum Alloy Specification

| Parameter | Value | Remark |

|---|---|---|

| Alloy | 3003H14 or 1050 | Aluminium Grade |

| Temper | H14 (strain hardened) | Toughness vs formability balance |

| Thickness | 0.3 – 0.5 mm | Compatible for plates manufacture |

| Surface Treatment | Anodized | Ensures hydrophilicity in non-image areas |

| Surface Roughness | Ra ~ 0.25 µm | Optimizes coating adhesion |

| Impurities | Si < 0.60%, Fe < 0.50% | Limits impurities for grain uniformity |

Proper tempering of the aluminum plate enhances flexibility and ensures that the anodized layer consistent in density, significantly impacting developer application, on-press durability, and ink acceptance.

Typical Positive Offset Plate Developer

A precise developer chemistry allows the removal of laser-exposed image-free areas (called the “negative” image in lithography terminology) to uncover the anodized aluminum exposing hydrophilic surfaces essential for ink repellency.

| Component | Description | Typical Concentration (%) |

|---|---|---|

| Sodium Carbonate | Primary alkaline agent | 2.0 – 5.0 |

| Sodium Metasilicate | Enhances cleaning power | 0.5 – 1.5 |

| Sodium Sulphite | Controls oxidation | 0.1 – 0.3 |

| Surfactants | Wetting agent and surface activity | Trace levels |

| Water | Carrier solution | 85 – 97 |

pH Values: 11.5 to 12.5 depending on developer formulation.

The developer must maintain alkalinity and reducing characteristics to dissolve formed photopolymer selectively without weakening the integrity of the plate’s image area.

Implementation Standards and Process Parameter

Manufacturing and printing industries generally adhere to ASTM and ISO guidelines for offset plates:

- ASTM F2890-12 – Standard Specification for Site-Processed Thermal Positive-Working Lithographic Printing Plates.

- ISO 12635 – Thermal and processing testing directives of modern photopolymer plates.

Recommended Process Workflow:

| Step | Parameter | Detail |

|---|---|---|

| Imaging | Laser frequency | Depending on system but typically 2400 – 4000 ppi |

| Development | Temperature | 20 – 25 °C |

| Development time | 30 – 90 seconds | Adjust by plate brand/product instructions |

| Rinse | Water sprays and ethyl-based rinses | Remove developer residues |

| Drying | 50 – 60 °C | To prevent plate damage or rouge formation |

Optimizing timing and chemistry leads to finer DOI (Distinctness of image), minimal scumming, and outstanding press runlets potentially exceeding 500,000 impressions.

Chemical and Environmental Handling

Due to the alkaline nature of positive plate developers:

- Storage: Keep sealed in a translucent packed container away from direct sunlight.

- Waste Treatment: Thickener and solids in spent developer solutions require neutralization and expanded municipal waste handling techniques as per local environmental laws.

- Safety: Use nitrile gloves and chemical splash goggles during handling.

A balanced combination of premium CTP plate stock and accurately matched positive offset plate developer chemistry results in:

- Accurate image rendering and filmograhical density.

- High resistance to abrasion, reducing remakes caused by press failure.

- Streamlined processing and minimal working time promo economies.

Conclusion

Selecting the right CTP Positive Offset Plate and its accomplished developer solution maintains your offset efficiency, print quality consistency, and environmental compliance. Synchronizing parameters such as aluminum alloy, temper, coating, developer alkalinity, processing times, and adherence to international manufacturing standards guarante e newspaper value manufacturing toward future-ready print production.

For more specific formulation help and brand-specific optimization inquiries, consulting with plant technical specialist experts or vendor manuals is advised.

If you need a product datasheet or wish to arrange a technical training session for your printing staff on CTP plate processing — feel free to contact us.

Keywords: CTP Plate, Positive Offset Plate, Developer, Aluminum Alloy, Offset Printing, Printing Plate Chemistry, Processing Parameters, Printing Industry Standards

© 2024 Aluminium CTP Plate Solutions | All rights reserved.

If you’d like assistance writing auxiliary materials such as installation manuals, safety data sheets (SDS), or quarterly process optimizaton bulletins, just let me know!