Thermal CTP Plate Offset Printing Material

In the realm of modern printing technology, the development of Thermal Computer-to-Plate (CTP) systems has propelled the efficiency and precision of offset printing, ushering in a new era for commercial print operators. With active marketing success revolving around sustainability, reliability, and image quality, one component often tends to garner more attention than the acuity it provides: the thermal CTP printing plate material itself.

Redefining the CTP Landscape

At its core, thermal CTP refers to a process that transfers digital images directly to printing plates, thus eliminating traditional film-based imaging methods. The material used in making these plates is crucial to this process and can be evaluated from various angles beyond mere print quality. Thermal CTP plate material is no longer viewed solely as a functional tool but a multifaceted entity impacting wide-ranging printing applications.

The Intelligent Choice: Quality Meets Sustainability

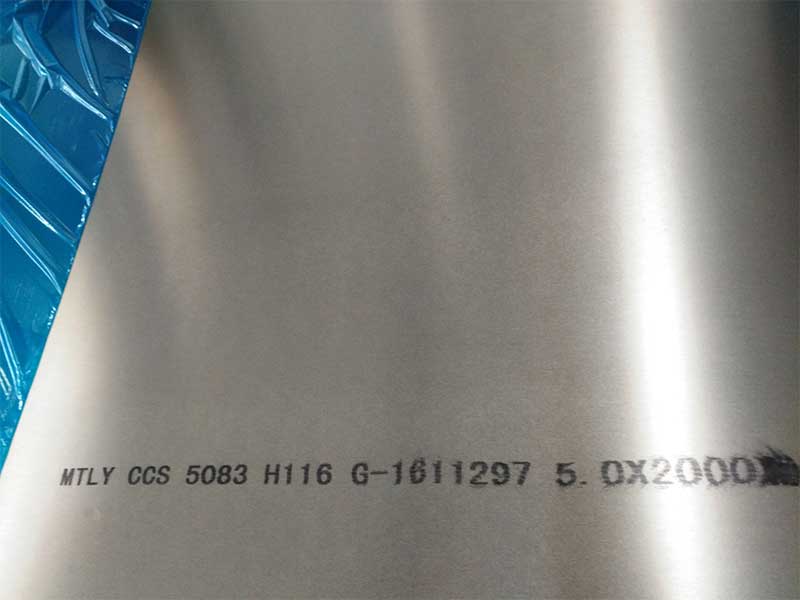

As customers become more aware of environmental considerations, printers must take a deeper dive into how CTP plates are produced and their ecological footprint. Thermal CTP plates made from aluminum alloys exhibit remarkable sustainability, especially with advancements in recycling processes. Many manufacturers create plates that are less energy-intensive to produce and seamlessly recyclable after their job cycle, mitigating the landfill pressure associated with used plates.

From a distinct viewpoint, sustainability can also influence purchasing decisions. Smart consumers are shifting towards brands that display ecological responsibility alongside operational efficiency. When choosing thermal CTP plates, the lifecycle—from sourcing aluminum to disposal—highlights a printer’s commitment to sustainable practices.

Beyond the Mechanics: Technological Synergy

However, the allure of thermal CTP plates extends from sustainability aspects into the technological realm. In them rests a marriage of innovation and practicality which aids printers in achieving superior outcomes. Not only do thermal CTP plates endow properties like greater sensitivity to laser exposure, leading to heightened tonal depth and sharper image replication, but they also interact efficiently with modern imaging technologies.

Tempering heatgradients during plate processing is crucial for quality assurance, directly impacting the on-press performance. Utilizing thermal CTP technology means adapting practices between printer operators, adjusting mid-production processes according to temperature nuances, and recognizing cultivation opportunities for machine efficiency.

Furthermore, thermal CTP plate attributes resonate harmoniously when integrated with creative workflow optimizations. Think in terms of quality control: the exactitude of thermal-sensitive materials is a game-changer. In contrast to conventional printing technologies, thermal plates allow printers to tackle tight registration tolerances, elevating spot or process-color quality to realms previously deemed unattainable.

Economics: Beyond Price Sentiment

Financial implications strongly govern materials procurement decisions. Businesses often perceive quality versus cost as the defining balance of choices. Thermal CTP plates, while commands an initial financial outlay, can actively contribute to economic savings through reduced setup times, longer plate life, and diminished material waste.

Let’s take a moment to recalibrate and dissect the perspective of “Total Cost of Ownership” (TCO). Integrating efficient thermal plates results not just in mind-numbing math regarding per-unit costs comparison; it incorporates time savings, labor efficiencies, and prioritization in maintaining expensive print equipment. What winterwear remains on the shelf—accompanies productivity; an undivided P&L fundamentally reflects benefit divergence.

Crafting a Unique Relationship with Print Quality

All these aspects can be difficult to distill into pure statistics or hard data, and it’s essential to explore some human elements involved, which lead to print quality authenticity rather than simply evaluating only the specifications. A printer’s relationship with thermal CTP plates transcends functional capacitation—it's an intimate bond shaped by expectations, reputational regards within industry circles, and a mutual with reputed suppliers dedicated to product excellence.

Printers who embrace anxiety-free solutions and safeguard communication lines built on respect often discover how CTP plate material’s release expands' vistas' of possibilities—it extracts deeper turns of creativity locked within production goals.

https://www.aluminumplate.net/a/thermal-ctp-plate-offset-printing-material.html