| Application | Offset Printing, Digital Printing |

| Spectral Sensitivity | 320-450nm |

| Resolution | 2-99% |

| Thickness | 0.15-0.30mm |

| Specification | 0.15mm 100PCS/box; 0.30mm 50PCS/box. |

| Developer Temperature | 23+/-2 Degree |

| Laser Energy Required | 80-180mj/Cm2 |

| HS Code | 3701302 |

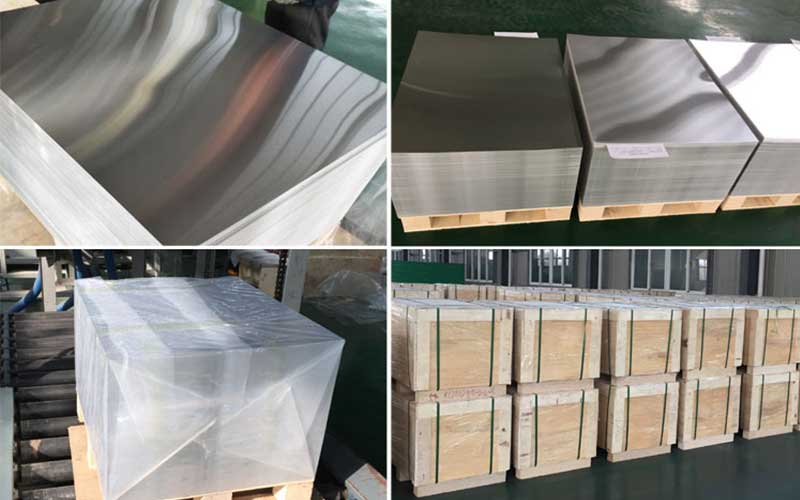

| Transport Package | Export Standard Seaworthy Package |

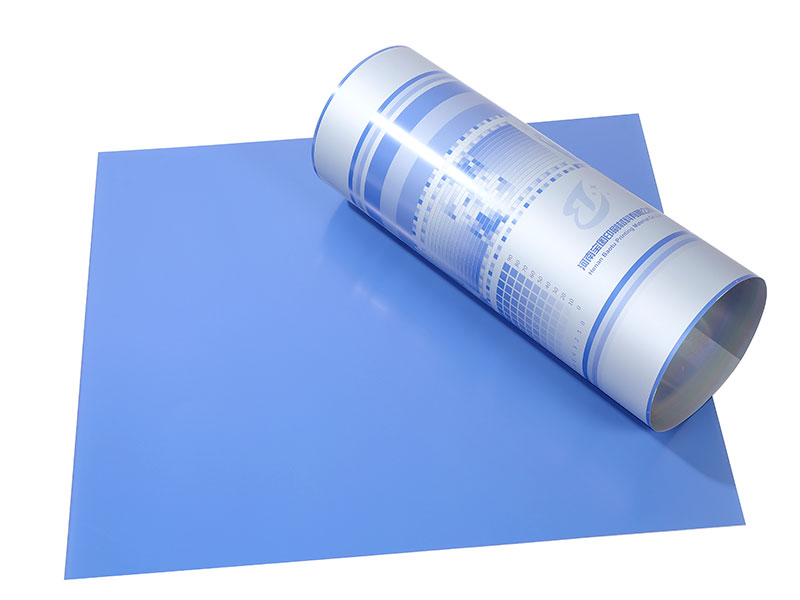

PS Plates, short for Photosensitive Plates, are a type of printing plate coated with a photosensitive layer. This layer undergoes chemical changes when exposed to light, making these plates an indispensable tool in offset printing. They serve as the medium that transfers images onto paper or other substrates, ensuring high-quality print outputs.

Composition and Structure

A typical PS Plate comprises several layers:

- Base Layer: Generally made from aluminum, this layer provides the necessary strength and stability to the plate. Aluminum's lightweight and durable properties make it an ideal choice for multiple print cycles.

- Photosensitive Coating: Applied over the base layer, this coating is where the magic happens. It reacts to UV light exposure, creating the image areas on the plate. The effectiveness of this coating is crucial for achieving sharp and precise prints.

- Protective Layer: In some PS Plates, an additional protective layer safeguards the photosensitive coating from scratches and environmental factors, enhancing the plate's longevity.

How PS Plates Work

The process of using PS Plates in printing involves several key steps:

- Exposure: The PS Plate is exposed to UV light through a film or a digital interface. The light hardens the image areas on the plate while leaving the non-image areas unaffected.

- Development: The plate is then processed using a chemical solution that washes away the unhardened, non-image areas, revealing a clear distinction between the image and non-image zones.

- Ink Application: The developed plate is mounted onto the offset press. Ink adheres only to the image areas, ensuring that the design is accurately transferred onto the substrate during printing.

- Printing: Finally, the inked plate comes into contact with a rubber blanket, which in turn transfers the image onto paper or other materials, completing the printing process.

Benefits of PS Plates

- High Precision: PS Plates allow for incredibly detailed image reproduction, making them ideal for high-quality print jobs.

- Cost-Effective: They offer a perfect balance between performance and cost, providing an economical solution for both short and long print runs.

- Durability: The robust nature of their aluminum base layer ensures they can withstand multiple print cycles without degradation.

- Versatility: PS Plates are suitable for a wide array of substrates, ranging from paper to more specialized materials, expanding their applicability across different industries.

Applications

- Commercial Printing: Magazines, brochures, and catalogs benefit from the precision and quality provided by PS Plates.

- Packaging: Cartons, labels, and flexible packaging often utilize these plates for vibrant and accurate color reproduction.

- Publishing: Books and newspapers continue to rely on the consistency and efficiency of PS Plates.