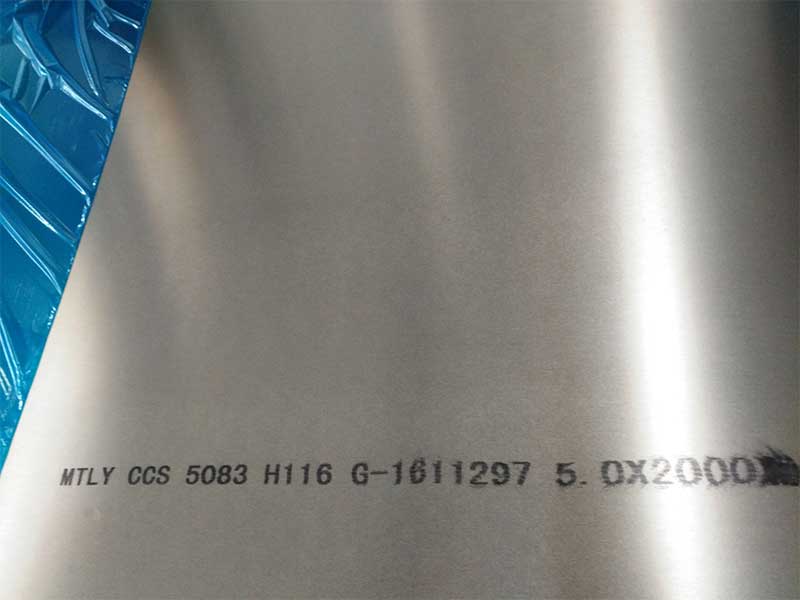

Aluminum sheet for Drilling processing

Applications of Aluminum Sheets in Drilling

Automotive Industry

In the automotive sector, aluminum sheets are drilled to create various components such as engine parts and body panels. The lightweight and durable nature of aluminum contributes to improved vehicle performance and fuel efficiency.

Aerospace Industry

Aerospace applications demand high precision and reliability. Aluminum sheets are extensively used in drilling various parts of aircraft, including fuselage panels and structural components, offering strength without compromising weight.

Electronics and Electrical Equipment

Aluminum sheets are often used in the production of electronic devices and electrical enclosures. Their corrosion resistance and thermal properties make them ideal for components that require precision drilling for integration into circuitry and housings.

Construction and Architecture

In construction, drilled aluminum sheets are used for creating facade elements, roofing, and decorative panels. Their attractive finish, combined with durability, makes them a preferred choice for architectural applications.

Considerations for Drilling Aluminum Sheets

Tool Selection: Using tools specifically designed for aluminum can enhance the drilling process, reducing wear and increasing lifespan. Carbide-tipped drill bits are often recommended for their durability and precision.

Lubrication and Cooling: Proper lubrication and cooling are essential to managing heat generation and preventing tool binding or damage during drilling. This ensures a clean, precise cut and prolongs tool life.

Drilling Speed and Feed: Optimizing the speed and feed rate is crucial in minimizing burrs and achieving a smooth finish. It's important to follow recommended guidelines based on the specific aluminum alloy and sheet thickness.

https://www.aluminumplate.net/application/aluminum-sheet-for-drilling-processing.html