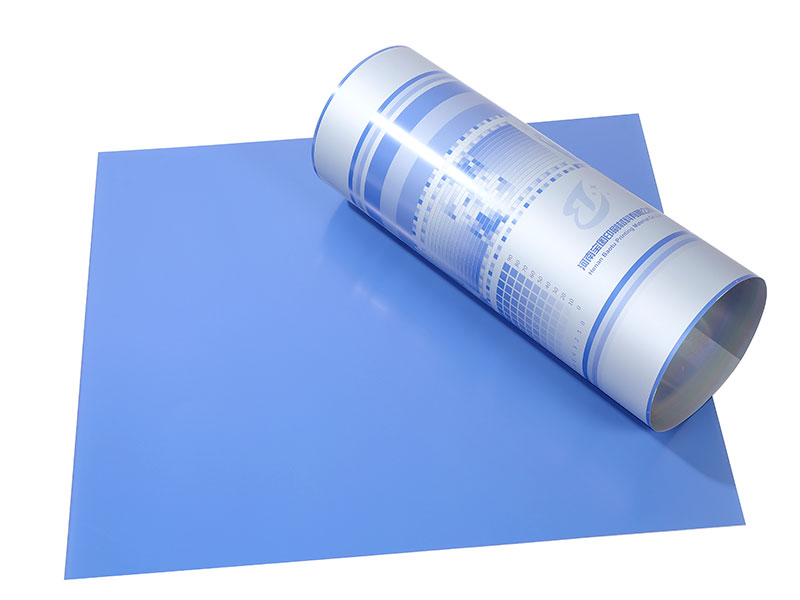

Thermal positive ctp plate

If you’ve ever marveled at a super-sharp magazine, brochure, or book, there’s a silent champion working hard behind the scenes: the thermal positive CTP plate. Sounds fancy and a tad intimidating, right? But it’s actually pretty interesting once you get into what it does and why it’s a game-changer in printing technology.

What Exactly Is a Thermal Positive CTP Plate?

Let’s break it down simply. CTP stands for Computer-To-Plate, which is just a high-tech way of saying this plate gets created directly from a digital image—without using the old-school film negatives.

The “thermal” bit describes how it’s made. Instead of relying on ultraviolet light, this plate’s imaging happens via heat, making the process more precise and less sensitive to ambient light. And the “positive” part? It means that the image areas correspond exactly to what you want printed—they come out as the ink-transferring areas, opposite the background.

How It Works: A Cozy Dance of Heat and Chemistry

Imagine this plate is kind of like a heat-sensitive sheet masked in a way that protects some parts while letting others change with a thermal pulse. When your CTP machine fires microscopic heat spots onto the plate’s surface, the exposed areas harden or alter chemically. These hardened image areas then attract ink during printing, while the unhardened parts repel it via water application.

What sets thermal positive plates apart is that the exposed (heated) areas correspond to your printable image—literally your content gets transferred through the heat action. In positive process terminology, exposed parts become ink-friendly impressions.

Immunity to Light? Yes, Please! Since thermal plates aren't UV light-sensitive, you don’t have to worry about special handling to prevent fogging. They’re much easier to store and handle in daylight.

Sharper Images, Finer Details: The heat-induced reaction produces a crisp image area, ensuring that good-quality halftones and fine lines remain sharp on outcomes like magazines and art prints.

Durability Under Pressure: In a fast-paced print shop, runs can be long, so plates must last. Thermal positive plates can deliver decent run lengths for commercial printing jobs without fatigue.

Environmental Wins: Some thermal positives are formulated without using chemicals that require tricky developing steps, shrinking waste and making post-processing friendlier.

Where Does This Plate Shine in the Real World?

Besides regular commercial printing—think flyers, menus, and brochures—thermal positive CTP plates find great use in:

Publishing houses aiming for vibrant book covers and jacket inserts.

Packaging printers who require precise image transfer with tactile texturing.

Specialized artwork printing like calendars or collector’s editions where fine detail matters.

Medium to long print runs that want a reliable, repeatable solution without running up processing costs or complexity.

Wrapping It Up

So if the printing world were a party, the thermal positive CTP plate might be that underrated friend who quietly makes sure everything runs smoothly—bringing precision, resilience, and simplicity to the table. By combining thermal imaging technology with positive working principles, it offers printers an agile, effective jump from pixel art on-screen to crisp, tangible prints.

Next time you pick up your favorite magazine or stunning leaflet, remember: a lot of the magic came down to a well-crafted thermal positive plate setting the stage for great ink to do its thing. Simple, smart, and crucial. That’s thermal positive CTP in a nutshell.

https://www.aluminumplate.net/a/thermal-positive-ctp-plate.html