| Application | Offset Printing, Digital Printing |

| Thickness | 0.15mm,0.20mm,0.25mm,0.30mm,0.40mm |

| Spectral sensitivity | 410nm |

| Exposure energy | 50 - 60 Mj/Cm2 |

| Developing temperature | 23+/-2 degree |

| Resolution | 2~98% at 200lpi |

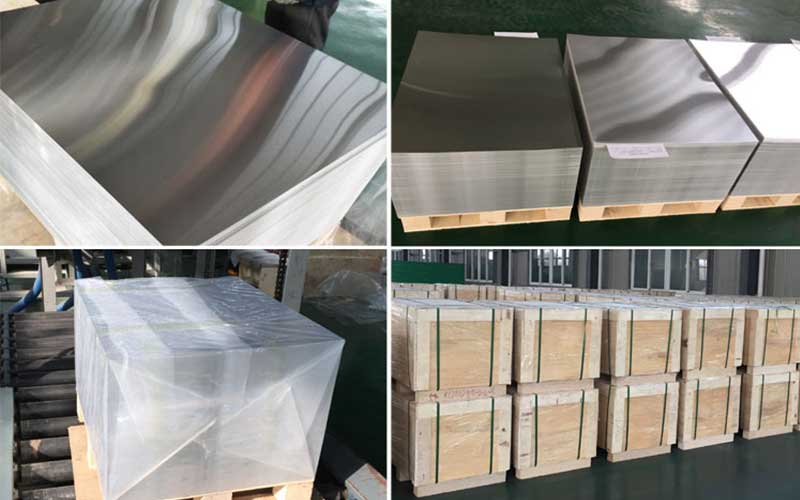

| Specification | 0.15mm 100PCS/box;0.25mm 50PCS/box;0.30mm50PCS/box; 0.40mm 30 PCX/box; customized. |

| HS code | 37013024 |

| Package | Export standard, seaworthy package |

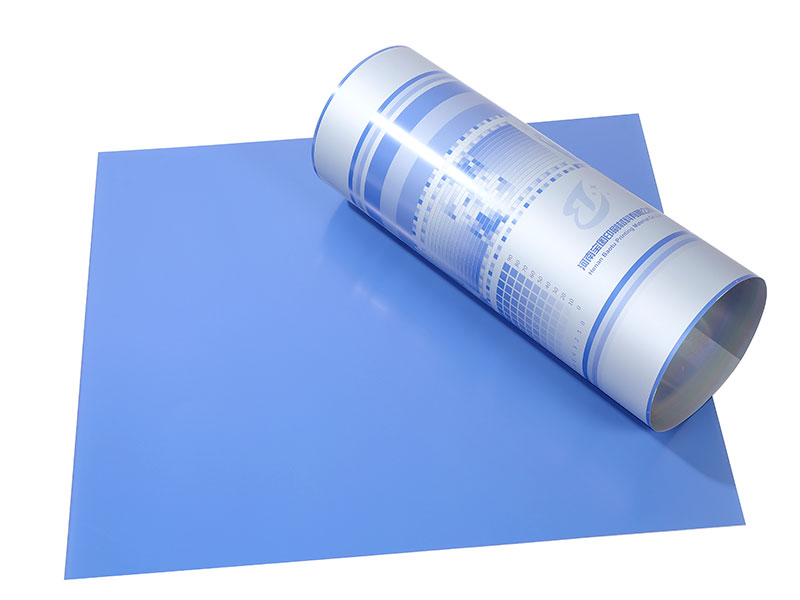

CTCP Plates, short for Conventional Thermal Computer-to-Plate, are an innovative type of printing plate that combines aspects of traditional plate-making with modern digital technology. They are designed to be exposed using ultraviolet (UV) light sources commonly found in traditional plate-making equipment, yet they leverage digital files for precision and accuracy in image creation. This hybrid approach makes CTCP technology a cost-effective solution that integrates easily with existing printing infrastructures.

Composition and Structure

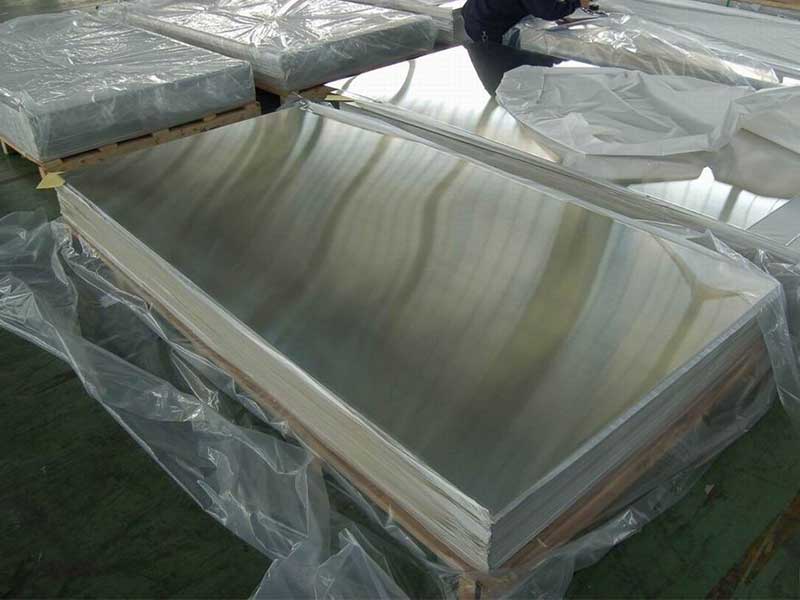

A typical CTCP plate consists of the following components:

Aluminum Base: The core structure providing rigidity and durability, ideal for maintaining accuracy during the printing process.

Photosensitive Coating: This coating reacts to light exposure, forming the image on the plate. It is specially formulated to respond to UV light, unlike purely thermal CTP plates which respond to thermal energy.

Surface Layer: Additional treatments on the plate’s surface can enhance durability and image fidelity, ensuring the longevity and clarity of the printed materials.

How CTCP Plates Work

CTCP plates streamline the plate-making process by utilizing a combination of traditional and digital techniques:

Image Exposure: The plate is exposed using a UV light source. The digital nature of CTCP technology allows precise control over image creation, ensuring high-resolution outputs.

Development: Following exposure, the plate undergoes a chemical development process that washes away unexposed areas, leaving the desired image intact.

Printing: Once developed, the plate is ready for mounting on a conventional offset press, seamlessly integrating into existing systems without requiring significant changes to equipment or processes.

Benefits of CTCP Plates

Cost Efficiency: CTCP plates offer a cost-effective solution by utilizing existing UV-based plate-making equipment, eliminating the need for costly thermal imaging systems.

High-Quality Output: The precise control over image exposure results in sharp, high-resolution prints suitable for detailed and vibrant designs.

Operational Flexibility: These plates fit well within traditional workflows, providing a seamless transition for printers looking to upgrade without overhauling their entire setup.

Environmental Considerations: Improvements in photosensitive coatings have reduced the environmental impact, as modern CTCP plates often require fewer chemicals in the development process.

Applications

Commercial Printing: Brochures, flyers, and advertisements benefit from the high-quality and cost-effective nature of CTCP plates.

Newspaper Printing: Offers a reliable and efficient means of producing high-volume prints quickly, essential for tight deadlines.

Book Publishing: Ensures clarity and precision in text and images, making it suitable for both educational and recreational publications.