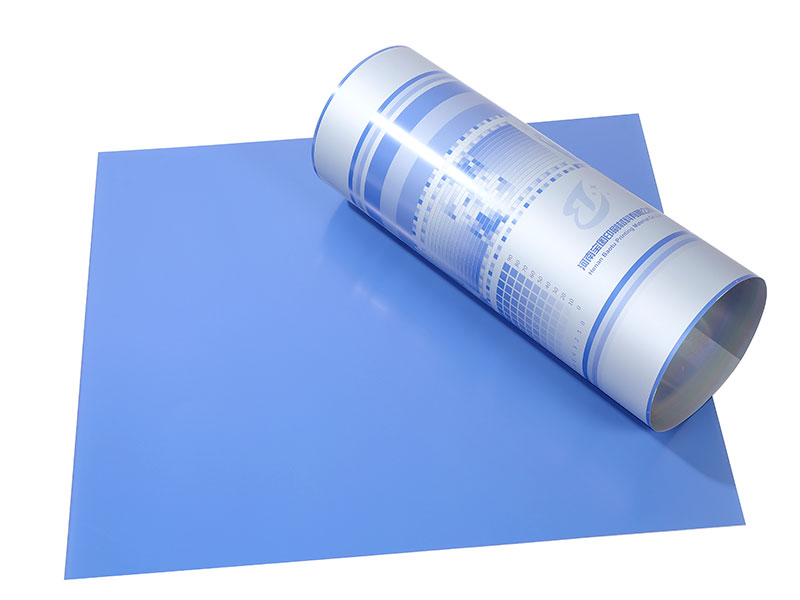

Aluminum thermal ctp plate

Aluminum Thermal CTP Plate: Features and Applications

The printing industry continuously evolves and adapts to introduce more efficient technologies that streamline operations while ensuring high-quality output. Among these innovations, the aluminum thermal CTP plate has become a staple in modern printing due to its unparalleled features and diverse applications.

What is Aluminum Thermal CTP Plate?

CTP, or Computer-to-Plate, refers to a technology that allows direct transfer of digital images to printing plates. An aluminum thermal CTP plate is specifically designed for this purpose, using thermal exposure to create high-definition images. This technology has transformed the workflow in commercial printing, leading to faster production times and enhanced print quality.

Features of Aluminum Thermal CTP Plates

-

High Image Quality: Aluminum thermal CTP plates excel in producing crisp, detailed images with excellent color fidelity. The plates allow for higher resolutions than traditional methods, which visually impact advertising materials, brochures, and other printed media.

-

Environmental Sustainability: Unlike traditional printing solutions that may require chemical processing, many aluminum thermal CTP plates utilize a thermal energy-based system that minimizes chemical use and waste. This environmentally friendly approach demonstrates the industry's commitment to sustainability.

-

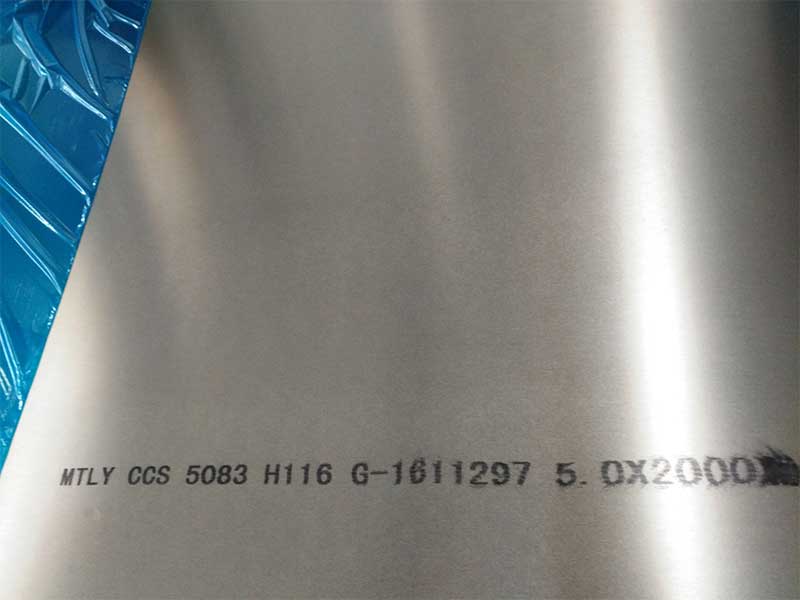

Durability and Longevity: These plates are manufactured from high-quality aluminum, which provides essential durability against wear and tear. This robustness translates into longer printing runs without sacrificing quality, making them a cost-efficient choice for printers.

-

Quick Turnaround Times: The efficiency of aluminum thermal CTP plates allows printers to produce high-quality prints in substantially shorter time frames. This feature is particularly valuable in highly competitive markets where time-to-market is crucial.

-

Cost-Efficiency: While the initial investment in creating CTP systems may be higher than traditional setups, the overall cost reduction in printing processes lowers production costs due to fewer manual steps and reduced chemical consumption.

-

Simple Workflow Integration: Aluminum thermal CTP plates can be seamlessly integrated into existing workflows, featuring automated systems that support fast, accurate plate creation right from digital files.

Key Applications of Aluminum Thermal CTP Plates

The applications of aluminum thermal CTP plates are vast and varied, catering to a broad audience in the printing sector:

-

Commercial Printing: Aluminum thermal plates are vital in producing high-quality materials such as posters, flyers, and brochures where color accuracy and design fidelity are paramount.

-

Packaging Printing: These plates are extensively used for packaging materials, where exact colors and high-resolution logos enhance branding and appeal attractively to consumers.

-

Publishers and Book Printing: In publishing, aluminum thermal CTP plates lead to sustainable printing practices while producing books with exceptionally crisp and clear text graphics.

-

Advertising & Banners: Aluminum thermal CTP technology makes printing large banners and advertising displays faster and more efficient, meeting tight deadlines without sacrificing visual quality.

-

Specialty Printing: Specialized applications, such as printing on unique substrates and custom backdrops for events, benefit from aluminum thermal plates due to their versatility and ability to handle multiple media types.

https://www.aluminumplate.net/a/aluminum-thermal-ctp-plate.html