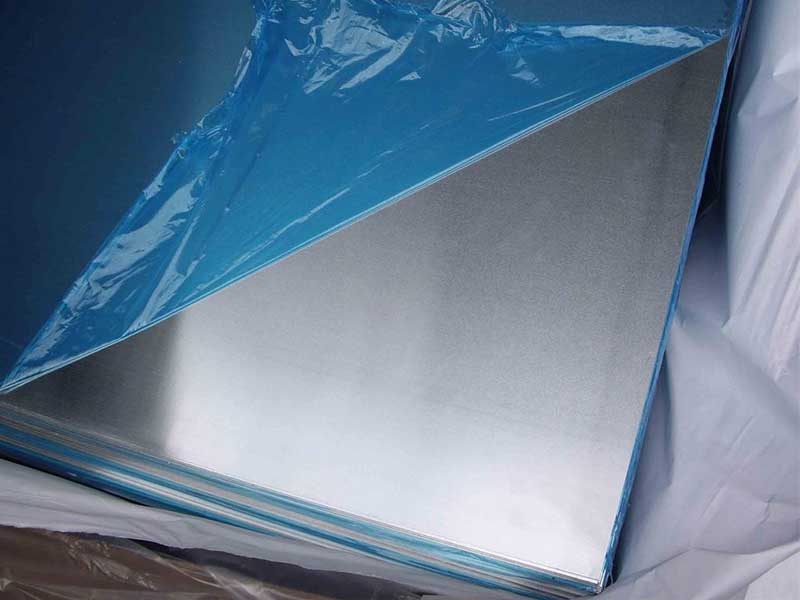

Blue Color Thermal CTP Plate

In the dynamic world of commercial printing, precision and efficiency reign supreme. Among the various innovations redefining plate-making processes, the Blue Color Thermal CTP (Computer-to-Plate) Plate stands out as a game-changer, expertly marrying advanced materials science with practical a printing application. Beyond its striking blue hue, this plate offers exceptional technical advantages for professional printing workflows.

the Blue Color Thermal CTP Plate

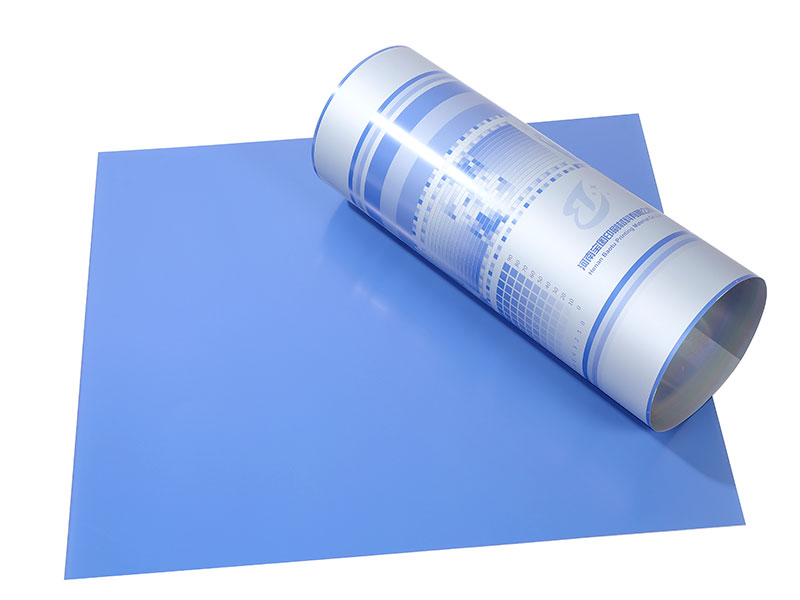

Thermal CTP plates serve as a direct link between digital image processing and traditional offset printing. The Blue Color Thermal CTP plate uses a sophisticated photosensitive layer enhanced by thermal polymerization technology. Upon exposure to infrared laser imaging, the blue-coated areas undergo a chemical transformation, creating a high-definition image layer inherently suited for offset printing.

Why Blue? The blue-colored coating is not merely aesthetic—it improves the optical contrast during and after imaging, facilitating cleaner imaging with fewer errors. This color distinction also aids in easier manual and automatic plate inspection prior to mounting on the press, ensuring quality control.

Core Functions and Roles in Print Production

Unlike conventional bromide or violet-based CTP plates, Blue Thermal plates offer:

- Enhanced Thermal Sensitivity and Thermal Stability: Adapting well to laser wavelengths of 830nm to 850nm, the plate polymerizes sharply without silver halides, minimizing detoxification phases and process chemistry waste.

- Robust Chemical Resistance: After development, these plates exhibit superior resistance to fountain solutions and inks during long press runs, which translates to fewer plate swaps and more stable print results.

- Fine Detail Resolution and Dot Reproduction: Blue Thermal plates achieve imaging at 2% to 98% dot gains, essential for sharp text and image clarity in premium brochures and packaging.

- Elimination of Conventional Chemical Processing: Many blue thermal plates support processless or chemistry-free development, drastically reducing environmental impact and operational costs.

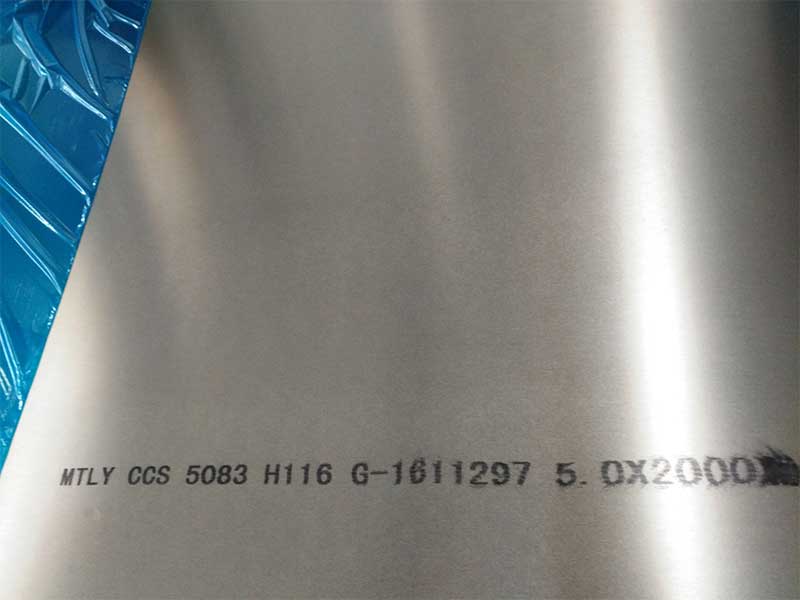

Alloy Tempering and Plate Base Specifications

The structural integrity of CTP plates hinges on the aluminum substrate beneath the photosensitive layer. Typical high-quality Blue Thermal CTP plates use annealed aluminum alloy 1050 or 1060, known for optimum flexibility and good thermal conductivity. This guarantees:

- Uniform laser energy absorption and heat dissipation.

- Resistance to mechanical deformation during press mounting.

- Excellent corrosion resistance for longevity.

Temporary Alloy Tempering Standard: H18 temper is often specified to maintain a balance between stiffness and flexibility during high-volume anilox roller engagement.

Technical Parameters

| Parameter | Specification |

|---|---|

| Plate Thickness | 0.30 - 0.40 mm |

| Aluminum Alloy | 1050, 1060 (annealed, H18 temper typical) |

| Infrared Laser Sensitivity | 830 - 850 nm |

| Exposure Energy | 70 - 150 mJ/cm² |

| Processing Method | Processless or chemical development |

| Resolution Capability | Up to 2400 dpi |

| Maximum Run Length | 150,000 impressions |

| Dot Reproduction Range | 2% - 98% |

| Ink Compatibility | Alcohol and Alcohol-free fountain solutions |

Chemical Properties and Processing Conditions

The protective polymeric chemical composition layer attached to the substrate demonstrates:

| Chemical Component | Description |

|---|---|

| Photosensitive Polymer | Polymerizes upon IR laser exposure |

| Hydrophilic GEL coating | Ensures non-image areas retain water, critical to short runtimes |

| Adhesion Polymer Matrix | Maintains coating attachment under mechanical abrasion |

In aqueous processing variants, a developer containing mild alkaline agents such as sodium carbonate or sodium silicate removes non-imaged areas, with environmental residuals minimized.

Applications Impacting Industry Performance

Blue Color Thermal CTP plates thrive in mediums requiring fast, high-resolution image production combined with unmatched durability, such as:

- Commercial Print Shops: Delivering sharp text on a massive scale with proofed environmental standards.

- Packaging Printing: Optimal for flexible packaging sheets or carton printing requiring vivid periodic elements.

- Newspapers & Magazines: Benefit from rapid plate processing times and reduced downtime in tight deadlines.

- Label Printing: Accuracy in thin lines and microtexts with strong scrap and reclamation rates.

https://www.aluminumplate.net/a/blue-color-thermal-ctp-plate.html