4x8 Mirror 6063 T6 Alloy Mill

In the bustling world of aluminum extrusion and rolling mills, the term “4x8 Mirror 6063 T6 Alloy Mill” might read like a technical jargon string at first glance. Yet behind this phrase exists a fascinating narrative of meticulous craftsmanship, scientific precision, and versatile utility.

Decoding the Terminology

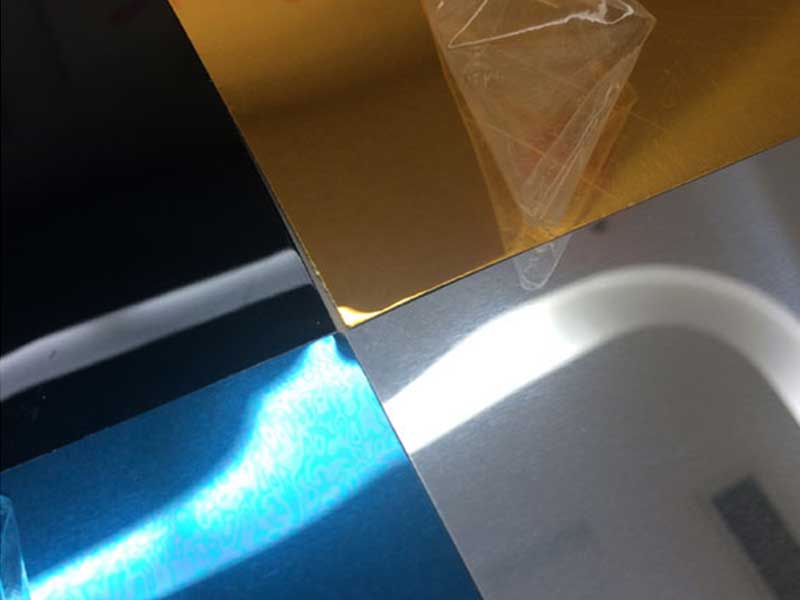

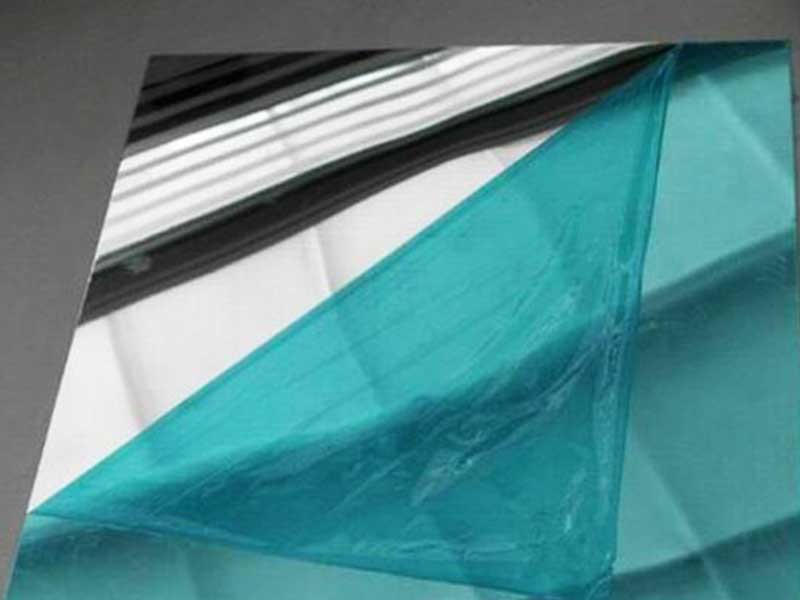

4x8 Mirror: The "4x8" refers to the dimensions, four feet by eight feet, which essentially is a standard sheet size commonly employed for aluminum panels, architectural cladding, signage, and more. The “Mirror” specifies the finish of the aluminum sheet—it has undergone a high-precision polishing process that transforms an otherwise utilitarian alloy surface into a shining, reflective plane comparable to a glass mirror.

6063 Alloy: In the aluminum alloy world, 6063 is celebrated for its balance of strength, corrosion resistance, and excellent extrusion characteristics. Known formally under the Aluminum Association designation UNS A96063, this magnesium and silicon-based aluminum alloy is popular for architectural extrusions, such as window frames, doors, and piping, offering both durability and excellent surface finish adaptability.

T6 Temper: The T6 temper is a heat-treatment condition — a solution heat-treated and artificially aged state — which significantly enhances the mechanical properties of 6063 alloy. This means the alloy sheet has been optimized for increased tensile strength and improved structural integrity, making it a reliable option in demanding settings.

Industrial and Aesthetic Versatility

What makes the 4x8 Mirror 6063 T6 Alloy Mill products both intriguing and practical is their capacity to serve dual purposes. The mill-finished mirrored surface combines significant industrial grade strength with a visually appealing finish, paving the way for creative uses that would otherwise rely on stainless steel or glass—often at a higher cost or weight penalty.

For instance, in decorative architecture, the reflective panels can act as dynamic façades, bouncing natural light into spaces, enhancing daylight, and adding a dimension of luxury and modernity. Due to their strength and resistance undercover of T6 tempering, these panels remain both functional and durable, resisting weathering and maintaining their pristine finish over time.

Parameter Insights and Implementation Standards

| Parameter | Details |

|---|---|

| Standard Sheet Size | 4 feet x 8 feet (1219 mm x 2438 mm) |

| Alloy Type | Aluminum Alloy 6063 (Magnesium & Silicon based) |

| Temper | T6 (Solution heat treated and artificially aged) |

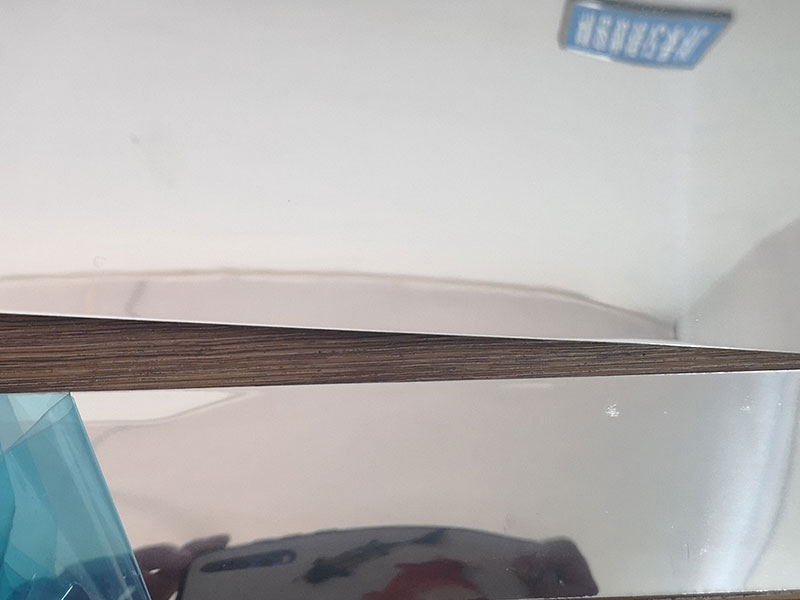

| Thickness Range | Typically between 0.5 mm and 3.0 mm |

| Mechanical Properties | Tensile Strength: approx. 210 MPa; Yield Strength: approx. 180 MPa |

| Corrosion Resistance | Excellent resistance to atmospheric corrosion |

| Surface Finish | Mirror polish, reflective finish (>85% reflectivity) |

| Production Process | Mill polishing, tempering, and surface treatments compliant with ASTM B209 |

Chemical Composition of 6063 Alloy

| Element | Percentage (Weight %) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 0.45 – 0.9 |

| Silicon (Si) | 0.2 – 0.6 |

| Iron (Fe) | ≤ 0.35 |

| Copper (Cu) | ≤ 0.1 |

| Manganese (Mn) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.1 |

| Titanium (Ti) | ≤ 0.1 |

Why Choose 6063 T6 Mirror Finish Aluminum?

- Strength with Style: The T6 temper confers mechanical robustness capable of withstanding structural demands, while the mirror finish offers refined aesthetics for visible surfaces.

- Lightweight Yet Durable: Offering significant corrosion resistance and lower density compared to stainless steel or glass, making installations easier and cost-efficient.

- Sustainable & Recyclable: Aluminum’s recyclability mirrors modern industry demand for sustainable material choices.

- Customization Potential: Versatile thickness selections combined with mirror finishing open doors for creative, decorative architectural and signage solutions.

Maintenance and Care Guidelines

To sustain the mirror finish on 6063 T6 aluminum sheets, routine cleaning with mild non-abrasive detergents is advisable. Abrasive cleaners or rough sponges may compromise the polished appearance. Operating in marine or highly corrosive environments may require an additional protective clear coat.

In Conclusion

The 4x8 Mirror 6063 T6 Alloy Mill product stands at a compelling crossroads between science and art. From the mechanistic aperture of metallurgical composition and heat treatment to the elegant visual appeal afforded by pristine mirror finishing, it embodies the versatility and cutting-edge prowess of modern aluminum fabrication.

Whether used in a skyscraper's gleaming façade or an art installation’s dynamic reflective surface, the 4x8 Mirror 6063 T6 sheet proves aluminum’s enduring capacity to capture and amplify its surroundings — a true testament to engineering and aesthetic harmony.

https://www.aluminumplate.net/a/4x8-mirror-6063-t6-alloy-mill.html