CTP Plates Offset Printing Plates Thermal Plate CTCP For Office Newspaper

In the dynamic landscape of modern printing, delivering crisp, clear, and high-quality newsprint efficiently is pivotal. Central to this efficiency is the integration of advanced printing plates—in particular, CTP Plates for Offset Printing, often termed as Thermal CTCP Plates, designed specifically for office newspapers and similar print mediums.

CTP Plates in Offset Printing

CTP (Computer-to-Plate) technology enables direct imaging from digital files onto printing plates, bypassing traditional film-based methods. This innovation streamlines the workflows of newspaper offices who demand fast, precise printing. Offset printing, using such CTP plates, remains a dominant method thanks to consistent image reproduction and cost-effectiveness on large volume runs.

From my experience working with Aluminium CTP plates, the shift towards thermal CTP plates, particularly for applications like office newspapers, presents both advantages and challenges. The speed and automation offered by thermal CTP are undeniable, significantly reducing turnaround time compared to traditional methods. This is crucial for daily newspaper production where deadlines are incredibly tight. However, the finer details and overall print quality can sometimes suffer, particularly on plates requiring high resolution or extended print runs. We frequently find that the thermal development process, while faster, can be more sensitive to variations in temperature and humidity, leading to inconsistencies in plate quality if the environmental controls aren't meticulously maintained. This requires stricter process monitoring and potentially higher upfront investment in climate-controlled environments.

Furthermore, the choice between different types of thermal CTP plates – for instance, those optimized for speed versus those prioritized for longevity – is a critical one depending on the specific printing press and operational priorities. A newspaper print shop focused on rapid turnaround of multiple editions daily might favor a speed-optimized plate, accepting potentially shorter plate life. Conversely, a less time-sensitive publication might opt for a more durable, higher-resolution plate even if it means a slightly longer processing time. Careful analysis of the overall cost-per-print, considering plate cost, press downtime, and ink consumption, is crucial for making an informed decision that aligns with the publication's specific needs and budget. We often advise clients to conduct thorough print tests with different plates to determine the optimal balance

Thermal CTP Plates (CTCP) use a heat-sensitive polymer coating on an aluminum substrate, which reacts when exposed to near-infrared laser, forming the printable image. Unlike conventional plates requiring chemical processing, thermal plates are easily imaged and develop through thermal and pressure methods, reducing environmental waste and speeding up production.

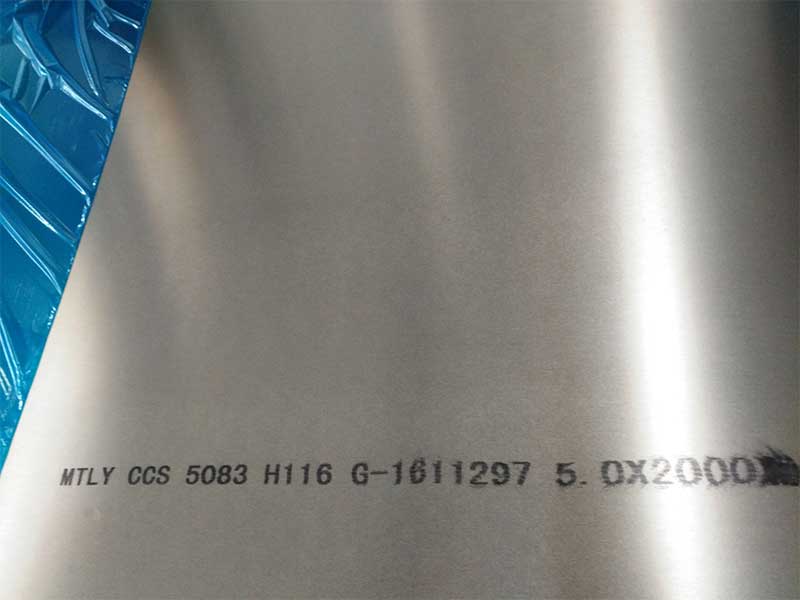

The Role of Aluminum in Thermal CTP Plates

The backbone of modern ATP (Aluminum Thermal Printing) plates largely revolves around aluminium substrates, prized for their balance of strength, lightweight properties, versatility, and surface finish needed for even coating application.

Aluminum Alloy & Temper Used:

| Parameter | Specification |

|---|---|

| Alloy Type | 1060, 1100 H14 or H16 (with >99% pure aluminium) |

| Temper | Half-hard to Full-hard (H14-H16) temperedizes for precise surface flatness and hardness |

| Thickness | Typically 0.30 mm - 0.40 mm |

| Width & Length | Customizable to printing press requirements |

The tempering through cold rolling provides a surface hardness adequate to withstand imprint pressure and feeding in high-speed offset presses while retaining sufficient flexibility for wrapping around cylinders and cylinders.

Implementation Standards and Surface Treatment Conditions

Surface preparation for thermal CTP plates adheres strictly to industry standards like ISO 12647-7:2016 (Graphic technology—Process control for the production of halftone color separations) to ensure color consistent reproduction and plate topography suitable for uniform photosensitive layer adhesion.

Process parameters typically implemented before lamination:

- Electrochemical Metallic Treating:

- Etching to microroughen the aluminum surface for ink receptivity.

- Anodizing (usually to about 15 microns thickness) to create a highly porous oxide layer holding photosensitive coating better.

- Grain and Surface Hardness:

- Roughness in a range Ra 0.30–0.40 µm enables optimal water/oil balance during printing.

- Surface hardness around 65–80 HV ensures durability for left runs up to 150,000 impressions without ring marks or ink variations.

- Chemical Coating Layer:Thermal polymer coatings are complex composites:

| Component | Function |

|---|---|

| Heat-sensitive diazo-polymer | Changes solubility under IR laser |

| Hydrophilic binders | Aid in water retention on non-image areas |

| Cross-linking agents | Enhance durability |

After this, plates are conditioned in thermostatic environments at ~25°C±2 and 45-55% humidity zones.

Chemical Properties of Aluminum Substrate

| Element | Minimum (%) | Maximum (%) | Role |

|---|---|---|---|

| Al | 99.0 | 99.9 | Main metal, lightweight |

| Fe | 0.40 | 0.70 | Increases strength, reduces corrosion sensitivity |

| Si | 0.20 | 0.60 | Increases wear resistance |

| Cu | - | 0.05 | Impurity, low impact |

| Mn | - | 0.05 | Counteracts grain growth; strength stabilizer |

| Mg | - | 0.03 | Inhibits recrystallization |

| Ti | - | 0.03 | Grain refiner |

This specialist alloy balance reflects a perfect trade-off between printable surface quality and longevity during continuous runs.

Unique Benefits and Why It Matters for Office Newspaper Printing

Office-based newspaper printing demands quick turnarounds, cost efficiency, and consistent quality output. Thermal CTCP plates marry these requirements with:

- Chemical-free Processing: Reduces environmental impact and cutting down waste disposal overhead.

- Fast Imaging Time: Suitable for quick edits necessitating agile headline changes.

- Long Durability: Copes with small to medium print runs, sustaining fine image fidelity.

- Easy Handling & Storage: Aluminum's resistance to bending/flexing aids transportability and faster mounting.

Final Thoughts

Thermal CTP Plates for offset printing—NB Newspapers and office-required runs—offer a cutting-edge synthesis of material science and printing technology. By the subtleties of aluminum alloy temper, processing treatment, and chemical nature behind these thermal plates, printers not only maximize output quality but also reduce costs, accelerate workflows, and maintain sustainable practices. This holistic appreciation cements Aluminum thermal CTP plates as indispensable tools for the contemporary office newspaper environment, blending precision, speed, and durability in an intricate yet accessible package.

Keywords:

CTP Plates, Thermal Printing Plates, Aluminum CTP Plates, Offset Printing Plates, Newspaper Printing, Thermal CTCP, Print Alloy Temper, CTP Plate Specifications, Electrochemical Etching, Anodizing Aluminum, Print plate substrate, Environmentally Friendly Printing