Mirror 1100 6063 T6 Alloy Mill

In an era where aesthetics and durability are paramount, the Mirror 1100 6063 T6 Alloy Mill stands out as a prime example of engineering excellence. This alloy, characterized by its high strength-to-weight ratio and reflective surface, is gaining traction in diverse sectors, catering to both functional and visual demands.

the Alloy: Why 1100 6063 T6?

Before delving into specific applications, it's essential to understand the makeup of the Mirror 1100 series. Aluminum Alloy 1100 is known for its excellent corrosion resistance, high thermal conductivity, and admirable workability, making it an excellent selection for environments requiring durability without sacrificing weight.

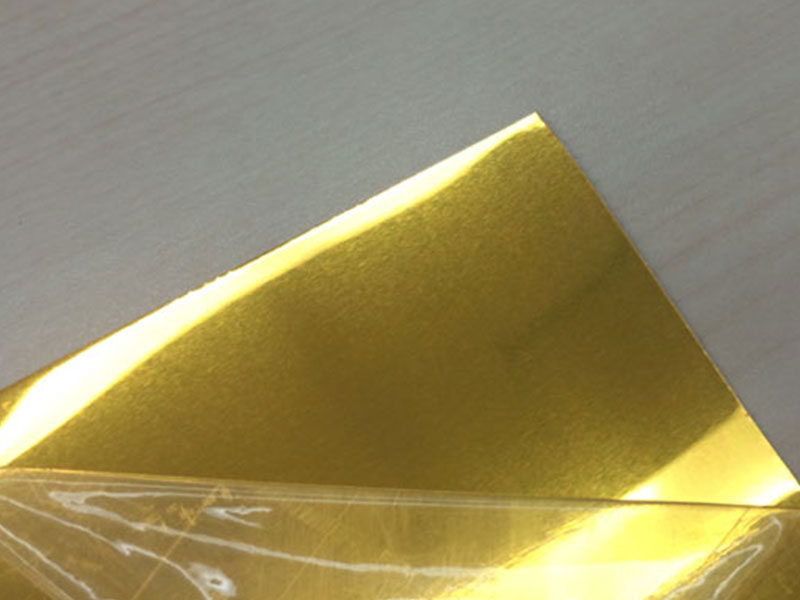

The 1100 and 6063 T6 alloys present distinct challenges in achieving a superior mirror finish on aluminum sheets. While 1100, with its high purity, offers excellent reflectivity and is relatively easier to polish to a high gloss, its softness makes it susceptible to scratching and marring during handling and processing. This necessitates meticulous care throughout the entire production line, from careful coil handling and precise leveling to specialized polishing techniques and protective packaging. Achieving a consistently flawless mirror finish with 1100 requires close monitoring of surface cleanliness and employing advanced polishing techniques like electropolishing to minimize surface defects.

Conversely, 6063 T6, a stronger and more workable alloy, presents its own set of difficulties. Its higher strength, while beneficial for certain applications, means it's more challenging to achieve the same level of surface reflectivity as 1100. The T6 temper contributes to a potentially harder, less uniform surface, demanding more aggressive polishing methods which can lead to increased material removal and potentially uneven results. Careful control of the polishing parameters, including abrasive type, grit size, and pressure, is paramount to striking a balance between achieving a high-quality mirror finish and maintaining surface integrity. the inherent properties of each alloy is critical for optimizing the milling and finishing processes to meet demanding aesthetic standards for "Mirror Aluminum Sheet."

The 6063 T6 designation indicates a specific heat treatment process that enhances mechanical properties, effectively increasing strength while retaining malleability. The resulting mill finish facilitates a reflective surface, which not only serves aesthetic purposes but can also enhance performance in specific applications.

The Reflective Property: More Than Just Aesthetics

The shiny, mirror-like finish of the 1100 6063 T6 Aluminum Sheet transcends aesthetics, enhancing functionality in various applications. The reflective quality allows the material to redirect light, making it a practical solutions for energy-efficient designs in architectural elements. For instance, when used in facade designs, it can help reflect sunlight, reducing heat absorption and ultimately ensuring lower energy costs for cooling systems within a building.

Versatile Applications in Industries

-

Architectural Design: The artsy engagement of mirrored finishes can bring modernity and dynamism to both exterior and interior elements of constructions—be it office towers or luxury apartments. The lightweight nature of the 1100 6063 T6 Alloy makes it ideal for large panels without compromising structural integrity.

-

Automotive Enhancements: The automotive industry embraces the aesthetic appeal of mirror finishes, employing the alloy in both exterior designs and interior fittings. Components like trims and moldings don't just look good but benefit from enhanced corrosion resistance and lightness, helping improve overall vehicle efficiency.

-

Consumer Electronics: The sleek, stylish surfaces produced by the mirror finish also find their way into the electronics market. Mobile device bezels and lightweight computer casings made from this alloy provide optimal protection while contributing to an appealing look.

-

Signage and Displays: Custom sign makers have increasingly added the Mirror 1100 6063 T6 Alloy Mill to their repertoire, opting for it in color-anodizing processes that miniaturize fingerprints and smudges. The reflective qualities combined with durable resilience position it as a standard for both permanent outdoor signage and eye-catching displays.

Technical Details: The Trophy of Innovation

The physical attributes of this alloy are a deep source of pride. With a density of approximately 2.7 g/cm³ and a tensile strength exceeding 240 MPa when treated to a T6 state, the alloy boasts longevity under load. The abilities to machine and fabricate with ease ensure the creation of bespoke configurations—from intricate designs to broader sheets—further highlighting its flexibility.

Another critical consideration is the excellent weldability of Alloy 6063, which allows for efficient production, preserving the mirror finish during processing. This welding capability is crucial in the manufacturing phase alliances necessary for complex products and architectural features.

https://www.aluminumplate.net/a/mirror-1100-6063-t6-alloy-mill.html