Violet Polymer CTP Plates Photopolymer Aluminum Negative for Offset Printing

In the world of offset printing, the precision and quality of the printing plates directly influence the final output. Among various technologies, the violet polymer CTP (Computer-to-Plate) photopolymer aluminum negative plates is know as a leap forward — marrying the robustness of aluminum substrates with the sensitivity and performance advantages of violet light curing.

The Fundamentals: Why Photopolymer Aluminum Plates?

CTP technology revolutionized printing by eliminating the need for film intermediates, offering better reproducibility and faster plate preparation. Within this, photopolymer plates have become preferred due to their sharp image definition and environmental benefits—the absence of classical wet processing (or a substantial reduction in chemicals).

The photopolymer layer applied to the aluminum substrate contains polymerizable compounds activated specifically by violet light (wavelength ~400nm). When exposed through a computer-controlled laser, the polymer hardens in the areas corresponding to the image, creating durable, hydrophobic (oil-attracting) image areas with hydrophilic (water-retaining) background regions.

Why Alcohol-Polished Aluminum? In Search of the Perfect Base

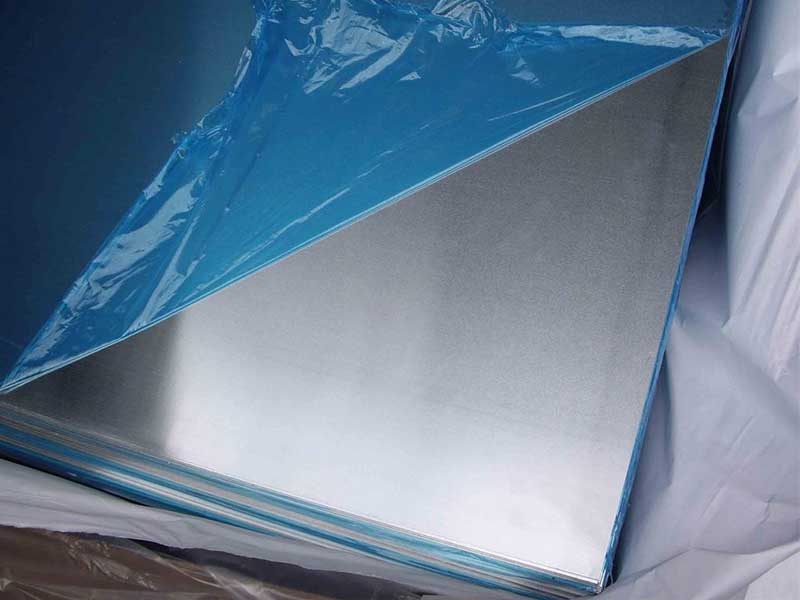

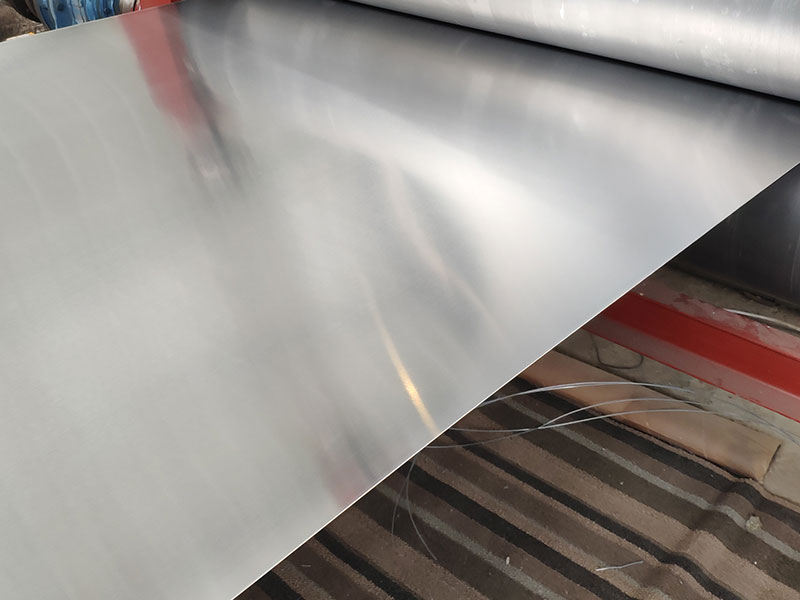

The choice of aluminum substrate is much more than an afterthought. Photopolymer CTP plates rely on the synergy between the photopolymer layer and the aluminum base. Typically, the substrate is made from aluminum sheets treated to achieve a smooth, anodized surface that increases hydrophilicity in non-image areas and adherence for the photopolymer layer.

What sets violet polymer CTP plates apart is the precision needed in the aluminum alloy's temper and chemical properties:

| Parameter | Typical Specification |

|---|---|

| Alloy Composition | 99.00% pure aluminum minimum (1100 series) |

| Temper | H-14, Rolled and Slightly Hardened |

| Thickness | 0.30–0.50 mm |

| Surface Treatment | Mechanical polishing + Electrochemical graining/Anodizing |

| Anodic Oxide Thickness | 1.0–2.5 microns |

The aluminum base must exhibit excellent flatness, surface uniformity, and consistent grain structures to ensure the photopolymer layer cures evenly. The common choice is 1100 aluminum alloy due to its excellent corrosion resistance and workability, tempered to H-14, granting stiffness but still allowing manageable vibration damping critical for printing stability.

Chemistry of Violet Photopolymer Layers

Unlike UV photopolymer plates, which cure at shorter UV wavelengths (around 360 nm), violet plates utilize LEDs with longer wavelengths suitable for dry thermal styles and environmentally safer lamps. These photopolymers comprise acrylate-based monomers, photosensitive initiators responsive to violet light, and crosslinking agents offering the negative image’s stability.

compositional elements:

- Polymers: Acrylic or methacrylic resins.

- Photoinitiators: Tailored to absorb at 395-to-410 nm.

- Adhesion promoters: To bond firmly to anodized aluminum.

Environmental and Practical Advantages

The violet CTP plates bring multiple benefits across the lifecycle of a printing press:

- Reduced chemical usage: Many violet plates adopt a “process less” or “low chemistry” development, minimizing water and solvent wastes.

- Laser-specific activation: Violet CTP machines are energy-efficient compared to traditional UV laser CTP systems.

- Durability: The hardened polymer film resists abrasion and solvents encountered in typical offset environments.

Final Thoughts: Synergizing Aluminum Science with Printing Excellence

Viewing violet polymer CTP photopolymer plates through the lens of material engineering—especially the subtle interplay between aluminum alloy properties and photopolymer chemistry—reveals why these plates remain at the forefront of modern offset printing. By selecting the right aluminum substrate, optimized for uniform anodizing and tempered strength, printing operators and manufacturers ensure consistent quality impacts and long press runs.

In essence, the humble aluminum plate beneath a sophisticated polymer layer is a triumph of materials science as much as of graphic technology. Its reliability and innovation pave the way to sharper prints, greener workflows, and higher productivity for offset printing facilities embracing violet polymer CTP plates.

Author's Note: For those seeking refined plate selection or customized aluminum alloys for CTP photopolymers, suppliers who also understand the metallurgy behind each sheet can significantly elevate printing production standards.