Chemical Compositions Marine Aluminum Sheet | |||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | Al | |

| Each | Total | ||||||||||

| 5A01 | Si+Fe≤0.40 | ≤0.10 | 0.30~0.70 | 6.0~7.0 | 0.10~0.20 | ≤0.20 | ≤0.15 | ≤0.05 | ≤0.15 | Remain | |

| 5454 | ≤0.25 | ≤0.40 | ≤0.10 | 0.50~1.0 | 2.4~3.0 | 0.05~0.20 | ≤ 0.25 | ≤ 0.20 | ≤0.05 | ≤0.15 | Remain |

| 5083 | ≤0.40 | ≤0.40 | ≤0.10 | 0.40~1.0 | 4.0~4.9 | 0.05~0.25 | ≤ 0.25 | ≤ 0.15 | ≤0.05 | ≤0.15 | Remain |

| 5383 | ≤0.25 | ≤0.25 | ≤0.20 | 0.7~1.0 | 4.0~5.2 | ≤ 0.25 | ≤ 0.40 | ≤ 0.15 | ≤0.05 | ≤0.15 | Remain |

| 5059 | ≤0.45 | ≤0.50 | ≤0.25 | 0.6~1.2 | 5.0~6.0 | ≤ 0.25 | 0.40~0.90 | ≤ 0.20 | ≤0.05 | ≤0.15 | Remain |

| 5086 | ≤0.40 | ≤0.50 | ≤0.10 | 0.20~0.70 | 3.5~4.5 | 0.05~0.25 | ≤ 0.25 | ≤ 0.15 | ≤0.05 | ≤0.15 | Remain |

| 5456 | ≤0.25 | ≤0.40 | ≤0.10 | 0.50~1.0 | 4.7~5.5 | 0.05~0.20 | ≤ 0.25 | ≤ 0.20 | ≤0.05 | ≤0.15 | Remain |

| 5754 | ≤0.40 | ≤0.40 | ≤0.10 | ≤ 0.50 | 2.6~3.6 | ≤ 0.30 | ≤ 0.20 | ≤ 0.15 | ≤0.05 | ≤0.15 | Remain |

| 6005A | 0.50~0.90 | ≤0.35 | ≤0.30 | ≤ 0.50 | 0.4~0.7 | ≤ 0.30 | ≤ 0.20 | ≤ 0.10 | ≤0.05 | ≤0.15 | Remain |

| 6061 | 0.40~0.80 | ≤0.70 | 0.15~0.40 | ≤ 0.15 | 0.8~1.2 | 0.04~0.35 | ≤ 0.25 | ≤ 0.15 | ≤0.05 | ≤0.15 | Remain |

| 6082 | 0.7~1.3 | ≤0.50 | ≤0.10 | 0.40~1.0 | 0.6~1.2 | ≤ 0.25 | ≤ 0.20 | ≤ 0.10 | ≤0.05 | ≤0.15 | Remain |

Mechanical Properties

5083 aluminum is renowned for its superior mechanical properties, making it suitable for structurally demanding applications:

Tensile Strength: Approximately 275-350 MPa

Yield Strength: Around 125-280 MPa

Elongation: Typically about 12-17%, providing a good balance of strength and ductility.

Corrosion Resistance

One of the standout features of the 5083 aluminum plate is its excellent resistance to corrosion, especially in marine environments exposed to saltwater. This property extends the longevity of structures and components made from this alloy.

Weldability

5083 aluminum exhibits excellent welding characteristics, allowing it to be used in complex structures where welding is required without compromising integrity or performance.

Applications of Marine 5083 Aluminum Plate

The 5083 aluminum plate is extensively used in the marine industry due to its superb corrosion resistance and strength. It is the material of choice for constructing ship hulls, decks, and offshore platforms. The alloy can withstand harsh marine environments, ensuring safety and durability.

Cryogenics

The 5083 alloy performs well at extremely low temperatures, making it a suitable choice for components and structures used in cryogenic applications.

Advantages of Using 5083 Aluminum Plate

Corrosion Resistance: Provides exceptional durability in saltwater and industrial environments, reducing maintenance and repair needs.

High Strength and Formability: Offers an excellent strength-to-weight ratio, allowing for the manufacture of robust yet lightweight structures.

Weldability: Ensures ease of fabrication and assembly, facilitating the construction of large, complex structures.

Versatility: Suitable for a wide range of applications, from marine to automotive and aerospace industries.

Recyclability: As with other aluminum alloys, 5083 is fully recyclable, supporting sustainable practices and reducing environmental impact.

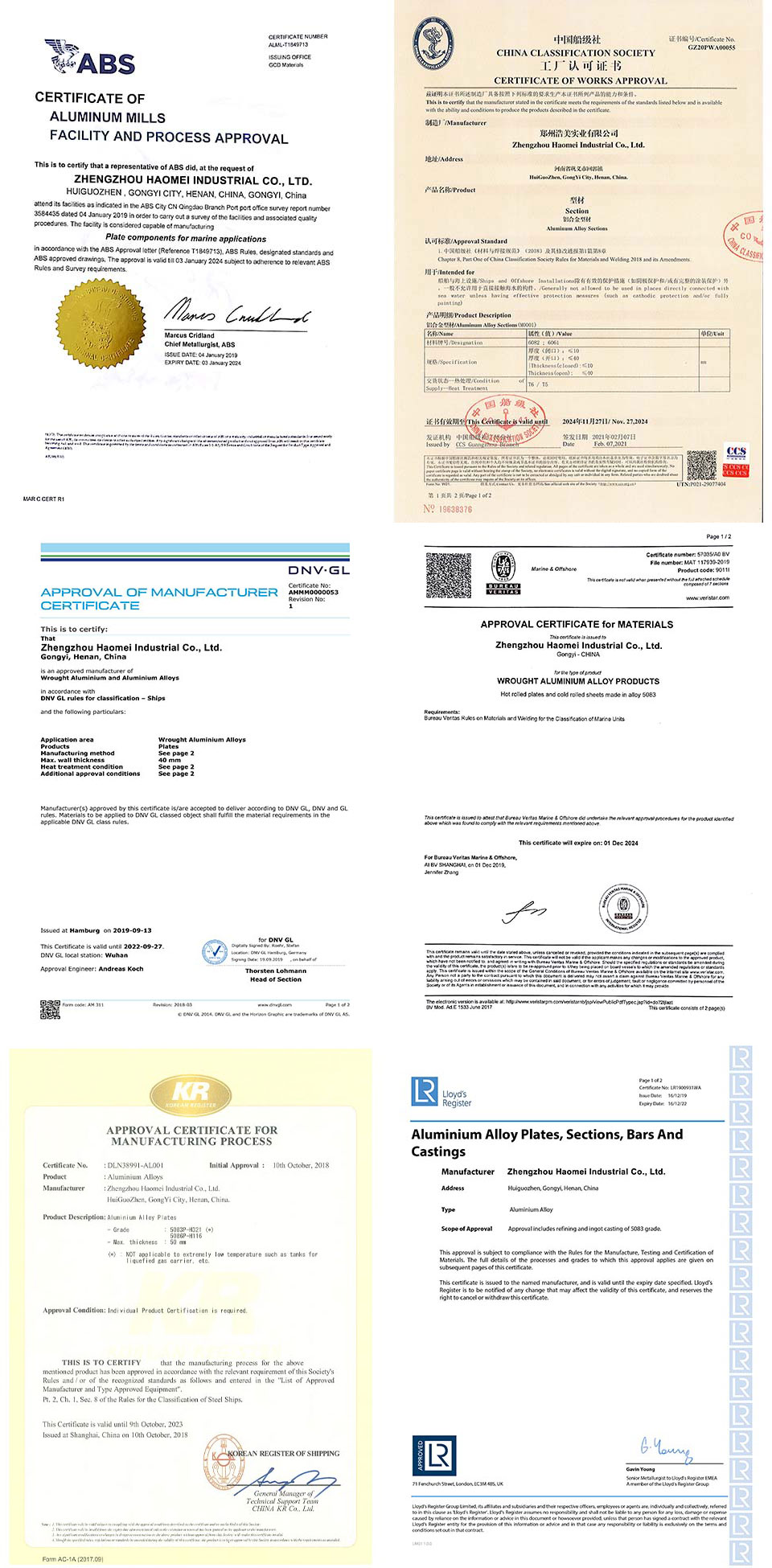

Certificate