Photopolymer Printing Plate Ctcp Plate 0.15mm to 0.4mm Uv CTP Plate

**Photopolymer Printing Plate CTP: A Unique Perspective on CTCP Plates 0.15mm to 0.

In the evolving world of printing technology, the demand for precision, durability, and environmental friendliness continues to grow. Among the myriad printing substrates, Photopolymer Printing Plates—specifically the CTCP (Computer-to-Plate) variant measuring 0.15mm to 0.4mm thick—represent a cutting-edge fusion of material science and high-resolution imaging intended for UV-curable CTP printing systems.

Photopolymer CTCP Plates

At the core, a Photopolymer CTCP Plate is a high-quality, UV-sensitive printing plate designed for direct image transfer from digital data to plate surface in a computer-to-plate workflow. This technology replaces traditional film-based processes, significantly reducing production time and enabling superior print precision. Typically, these plates range in thickness between 0.15mm and 0.4mm, tailored to different press requirements and image reproduction fidelity.

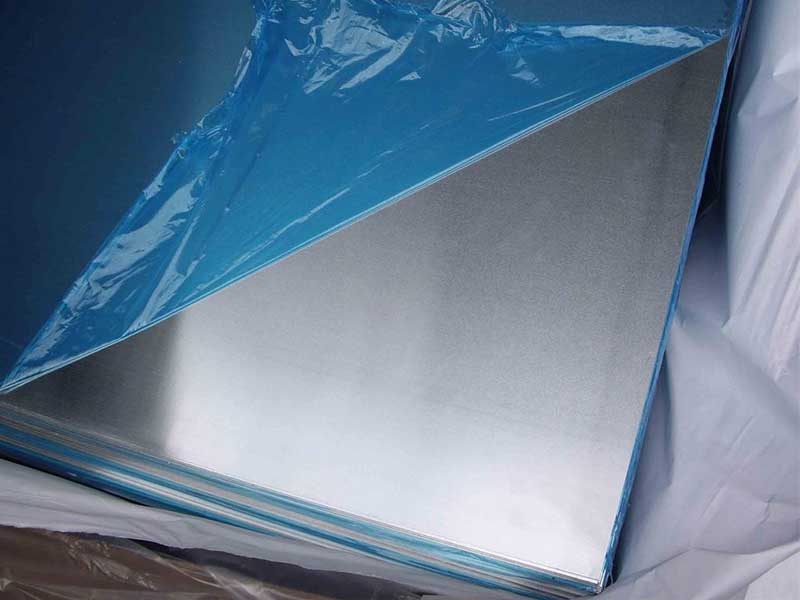

The primary materials involve an aluminum base with a photopolymeric coating sensitive to ultraviolet light wavelengths likely between 350nm to 420nm. This polymer top layer solidifies precisely where exposed during the UV computer-to-plate imaging process, creating hydrophobic image areas with non-printive hydrophilic surfaces remaining on unexposed sections for water retention.

Unique Functions from a Metallurgical and Photochemical Angle

What differentiates Photopolymer CTCP plates in the realm of printing substrates is its hybrid nature—a complex sandwich of metallurgical material engineering and advanced photochemistry. Aluminum serves as the substrate because of its:

- Corrosion resistance due to inherent aluminum oxide formation

- Superior thermal stability, maintaining dimensional stability under variable temperature cycles

- Optimal surface hardness after proper tempering

The overlaying photopolymer coating comprises polymer chains that cross-link upon UV exposure, hardening in nanoseconds while maintaining flexibility to withstand pressure across millions of printing revolutions.

Alloy temper designation primarily utilized falls within the 1000 and 3000 series aluminum. Typical tempering involves mechanical rolling combined with controlled annealing to yield a foil that is:

- Smooth and reflective to enhance UV exposure accuracy

- Small grain structural arrangement for high fatigue resistance

- Thickness ranged precisely from 0.15 to 0.4 mm according to press carrier and pressure needs.

Parameter Specifications for Photopolymer CTCP Plates

| Parameter | Typical Value / Specification |

|---|---|

| Aluminum Base Alloy | Al 1050 (purity ≥ 99.5%)* |

| Thickness | 0.15 mm to 0.40 mm (Flexible by order) |

| Temper | O-H12 (fully annealed soft to semi-hard bright) |

| Coating Photopolymer Type | UV Polymer resin, sensitive 350-420nm wavelengths |

| Exposure Energy | ~120 - 180 mJ/cm² (dependent on UV light source) |

| Surface Roughness (Ra) | 0.3 - 0.8 μm (optimized for ink adhesion) |

| Thermal Expansion Rate | ≈23 × 10^-6 / °C |

| Durability Runs | Up to 500,000 impressions depending on press type |

* 1050 aluminum is chosen for superior corrosion resistance and consistent mechanical elasticity profile.

Implementation Standards for Optimal Use

The effective use of Photopolymer CTCP plates follows internationally accepted standards to achieve high fidelity print effects and durability compliance:

- ISO 12647-2:2013 for process control in offset printing ensuring color reproduction standards;

- ASTM B209-21 for aluminum sheet materials providing purity and alloy standard;

- GRACoL guidelines to manage proof to press parameters maintaining process predictability;

- Appropriate temperature (18–22°C) and relative humidity (40–60%) to preserve dimensional accuracy post-imaging.

Chemical and Physical Properties

A concise chemical property overview of the aluminum substrate and photopolymer coating is essential for continuity in production processes:

| Property | Description | Value/Grade |

|---|---|---|

| Base Metal Composition | Primary metallic element | Aluminum 99.5% min (Grade 1050) |

| Protective Coating Composition | Photopolymer and lamination resin | UV-curable acrylate-based oligomers |

| Surface Hardness (HB) | Brinell Hardness | 15-28 depending on temper |

| Oxide Layer Thickness | Natural passive layer | 2–5 nm |

| UV Photopolymer Absorption | Target absorption bands | 350-420 nm wavelengths |

| Chemical Resistance | Resistance to mild acids/bases | Highly resistant (pH 4-10**) |

| Thermal Conductivity | Heat conductance capability | ~237 W/mK |

**pH 4-10 defines printing environment and eschews extreme conditions to safeguard polymer integrity.

Application Industries and Use Cases

Photopolymer CTCP Plates serve diverse sectors requiring impression quality combined with environmental safety. applications include:

- Commercial Printing: High-volume magazines, brochures with demanding color registering accuracy;

- Packaging: Flexible package design using UV curable inks on plastic, maintaining substrate dimension for press-long runs;

- Labels and Security Printing: Enhanced precision for small but high-impact icons and varnish printing;

- Periodic Publishing: Newspaper and periodic goods where warm, damp operational conditions prevail owing to UV-stable flexible polishing.