Chemical Composition

The 5052 aluminum plate is part of the 5000 series, which is primarily alloyed with magnesium. This composition provides a good balance of strength and resistance to corrosion. The typical composition includes:

Magnesium (Mg): 2.2-2.8%

Chromium (Cr): 0.15-0.35%

Manganese (Mn): 0.1% max

Silicon (Si): 0.25% max

Other elements in trace amounts, with the remainder being aluminum.

Mechanical Properties

The mechanical properties of 5052 aluminum are notable for providing both strength and flexibility, making it suitable for a range of applications:

Tensile Strength: Approximately 193-263 MPa

Yield Strength: Around 89-193 MPa

Elongation: Typically about 12-20%, which indicates excellent ductility and formability.

Corrosion Resistance

One of the defining features of the 5052 aluminum plate is its excellent resistance to corrosion, particularly in marine and saltwater environments. This makes it highly desirable for applications where durability and longevity are critical.

Workability

The 5052 aluminum plate is highly workable and can be easily welded, making it suitable for complex manufacturing processes. Its good formability allows it to be shaped into a variety of structures without cracking.

Applications of Marine 5052 Aluminum Plate

Due to its outstanding corrosion resistance, the 5052 aluminum plate is extensively used in the marine industry. It is commonly used for boat hulls, decks, and other components that require exposure to harsh saltwater environments. This ensures long-term performance and reliability.

Advantages of Using 5052 Aluminum Plate

Corrosion Resistance: Ideal for applications in marine and industrial environments where moisture exposure is prevalent.

Strength and Formability: Offers a robust combination of strength and ductility, making it easy to form and fabricate.

Lightweight: Contributes to weight reduction in transportation and structural applications, enhancing performance and efficiency.

Weldability: Shows excellent welding characteristics, simplifying assembly and fabrication processes.

Recyclability: As with other aluminum alloys, 5052 is fully recyclable, promoting sustainable practices and reducing environmental impact.

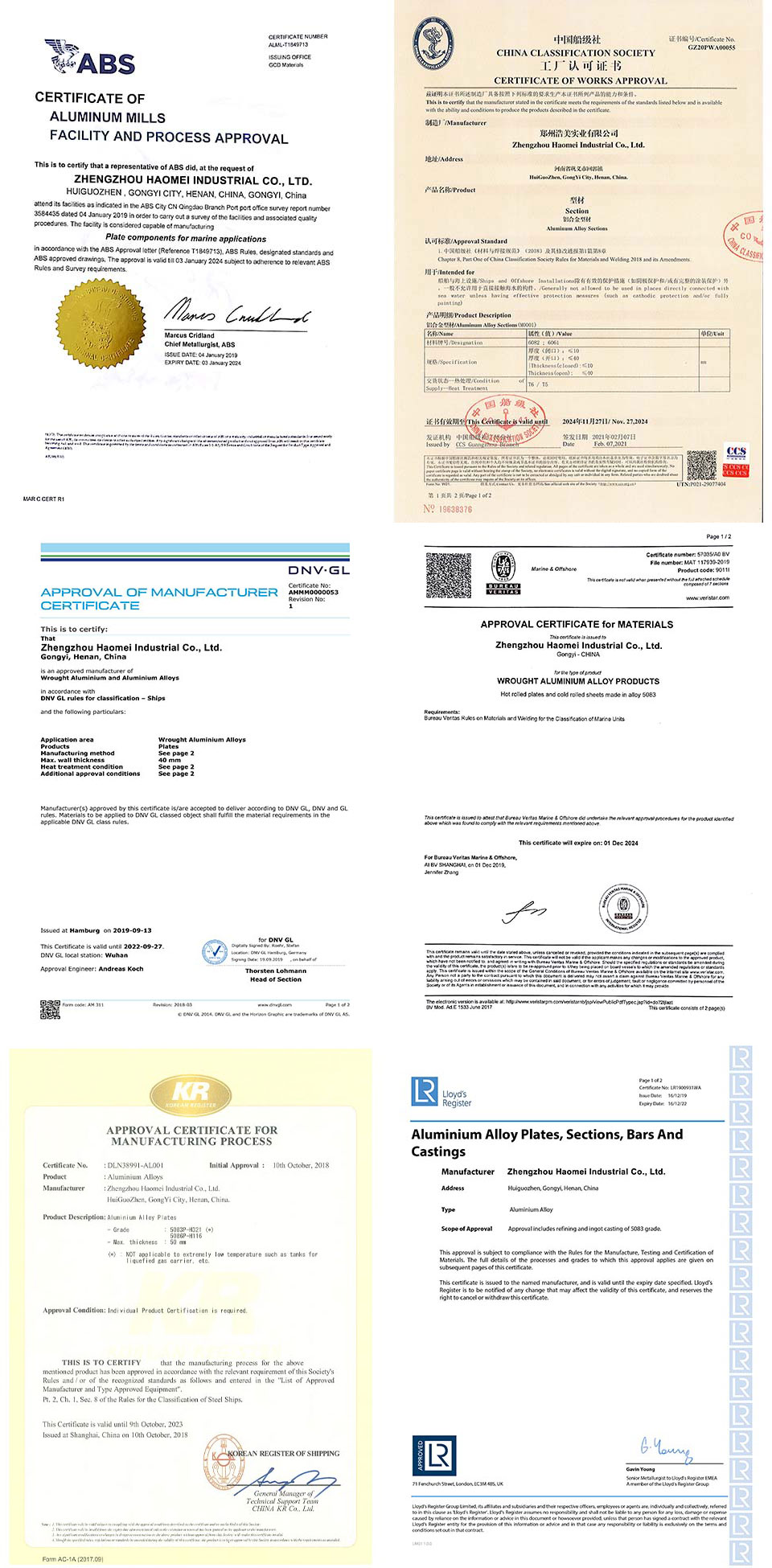

Certificate