Aluminum tread plate 1050 1060 5754 5052 3105 0.2mm

Aluminum tread plate is a versatile metal sheet widely used in industrial, architectural, and automotive applications due to its durability, corrosion resistance, and non-slip surface texture. Here, we provide a comprehensive overview of aluminum tread plate in popular alloys – 1050, 1060, 5754, 5052, and 3105 — all fabricated at a thickness of 0.2mm. This microscopic thickness layer enables easy forming and lamination, catering optimally to applications demanding light gauges combined with superior mechanical properties.

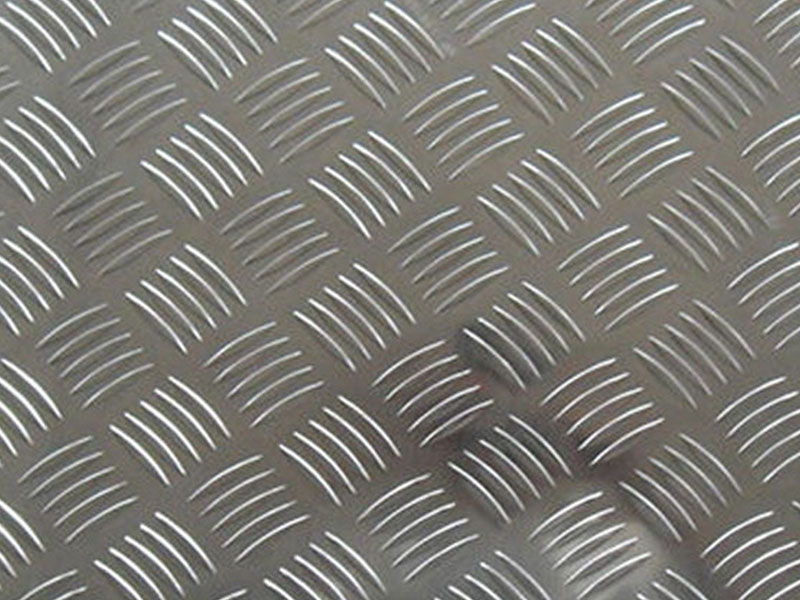

Aluminum tread plate, also called diamond plate or checker plate, features embossed surface textures that increase grip and prevent slippage in high-traffic or risky environments without amplifying the plate’s weight drastically. At a 0.2mm thickness, the plate balances flexibility and structural integrity ideally for light-duty surfaces, housings, or decorative panels.

Available Alloy Grades

1. 1050 Aluminum Tread Plate

- Type: Commercially Pure Aluminum (99.5% Al)

- Tempers: O (Annealed)

- Features: Excellent corrosion resistance, high ductility, excellent electrical and thermal conductivity

- Common Applications: Food processing plant floorings, light cabinetry panels

2. 1060 Aluminum Tread Plate

- Type: Commercially Pure Aluminum (99.6% Al)

- Tempers: O (Annealed)

- Features: Slightly higher purity than 1050, offering improved surface finish and corrosion resistance

3. 5754 Aluminum Tread Plate

- Type: Aluminum-Magnesium Alloy (5xxx series)

- Tempers: H111 (strain hardened and partially annealed)

- Features: Superior corrosion resistance, moderate strength, excellent weldability

- Applications: Marine platforms, ramps, interior panels requiring moderate strength and superb corrosion resistance

4. 5052 Aluminum Tread Plate

- Type: Aluminum-Magnesium Alloy (5xxx series)

- Tempers: H32, H34 (strain hardened and stabilized by heat)

- Features: Excellent corrosion resistance especially in marine environments, higher strength than pure Al

- Applications: Automotive splash panels, marine structures, chemical processing containers

5. 3105 Aluminum Tread Plate

- Type: Aluminum-Manganese Alloy (3xxx series)

- Tempers: H14 (strain hardened)

- Features: Good corrosion resistance, moderate strength, excellent formability

- Applications: Roofing and siding panels, fully recyclable decorative finishes smell through protection

Chemical Composition and Standards

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) | Al (%)* | Standard |

|---|---|---|---|---|---|---|---|---|---|---|

| 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.03 | ≤0.10 | ≤0.03 | Min 99.5 | ASTM B209 / EN485-2 |

| 1060 | ≤0.30 | ≤0.35 | ≤0.05 | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.05 | ≤0.03 | Min 99.6 | ASTM B209 / EN485-2 |

| 5754 | ≤0.40 | ≤0.50 | ≤0.10 | 0.50-1.0 | 2.6-3.6 | 0.15-0.35 | ≤0.10 | ≤0.03 | Balance | ASTM B209 / EN AW-5754 |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2-2.8 | 0.15-0.35 | ≤0.10 | ≤0.03 | Balance | ASTM B209 / EN AW-5052 |

| 3105 | ≤0.80 | ≤0.40 | ≤0.05 | 0.20-0.80 | – | – | ≤0.10 | ≤0.03 | Balance | ASTM B209 / EN AW-3105 |

Note: Aluminum balance comprises remaining mass.

Temper Designations and Mechanical Properties for 0.2mm Thickness

| Alloy | Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Surface Hardness (HB) |

|---|---|---|---|---|---|

| 1050 | O | 40-55 | 22-28 | >35 | 15-25 |

| 1060 | O | 53-67 | 28-35 | >25 | 25-28 |

| 5754 | H111 | 165-195 | 90-130 | 10-20 | 40-55 |

| 5052 | H32 | 185-230 | 110-160 | 10-15 | 50-65 |

| 3105 | H14 | 110-145 | 65-90 | 22-26 | 25-35 |

Surface Finish & Anti-Slip Characteristics

The characteristic tread or checker pattern is embossed in process through rolling with diamond or other dummy dies. Pattern options include:

Working with aluminum tread plate in a production environment, the specification "1050 1060 5754 5052 3105 0.2mm" immediately stands out as unusual, bordering on impractical. We typically don't see such a thin gauge (0.2mm) used for tread plate, especially not in those alloy designations. 1050 and 1060 are very soft, pure aluminum alloys, utterly unsuitable for the wear and tear a tread plate experiences. 5754, 5052, and 3105 are stronger, but even then, 0.2mm is extremely delicate – it would likely crease or dent during handling, let alone withstand any significant foot traffic or load. My guess is this specification is either a misprint, a custom order for a highly specialized, niche application (perhaps decorative rather than functional), or a sample run for testing purposes.

The challenge with such thin material isn't just structural weakness. Our manufacturing processes are optimized for thicker gauges. The rolling, cutting, and finishing stages would need significant adjustments, potentially leading to high rejection rates and increased production costs. Furthermore, the final product's dimensional stability would be questionable. The slightest variation in temperature or humidity could lead to warping. From a practical standpoint, this specification presents numerous processing hurdles and, frankly, I'd be surprised if

- Diamond (Raised Lines): Provides decisive slip prevention

- Flat Raised Diamonds or Circles: Increased gripping surface area

- Double-Stitching: Higher abrasion resistance for light aftermarket (excel in vehicle platform and equipment decks)

Compliance & Implementation Standards

Aluminum tread plates manufactured at 0.2mm thickness detailed herein typically comply with hands-on standards including:

- ASTM B209: Wide specification covering aluminum and aluminum alloy sheet and plate for strength, composition, and temper

- EN 485-2: European standard specifying dimensions and tolerances for aluminum strip and sheets, guaranteeing optimized lamination thickness

- RoHS & REACH compliant: No hazardous substances imposed, important for environmental applications

Typical Applications for 0.2 mm Aluminum Tread Plate Grades

| Alloy Grade | Typical Uses | Benefits |

|---|---|---|

| 1050, 1060 | Decorative panels, lightweight indoor surfaces, OEM utility covering | Pure aluminum for hygiene/chemical environments, excellent polishability |

| 5754 | Light marine decking, lightweight utility platforms, food equipment chassis | Weight savings, corrosion durability with moderate strength |

| 5052 | Chassis guards, fuel tanks shielding, precision shielding requiring moderate forming | Industrial grade corrosion minimum, isotropic mechanical performance |

| 3105 | Roofing equipment panels, thermal insulation components, indoor construction applications | Best formability, oxidation resistance, recyclability |

Storage and Handling Recommendations

- Store aluminum tread plates in a dry, shielded area to prevent oxidation beyond intrinsic protective layers.

- Avoid surface scratches; keep plates stacked with inert liners when stacking to prevent degradations to anti-slip functionality.

- Careful handling during the metal forming stage keeps optimal surface textures intact at thin gauge.

https://www.aluminumplate.net/a/aluminum-tread-plate-1050-1060-5754-5052-3105-02mm.html