Anodized Mirror Aluminum Coils 1050 1060

When it comes to modern manufacturing and design solutions, anodized mirror aluminum coils 1050 and 1060 have emerged as top choices among architects and industrial designers. Combining aesthetic appeal with robust functionality, these aluminum coils are prized for their unique reflective quality and durability. This article explores the myriad benefits and applications of these products and why they should be a staple in your inventory.

What Are Anodized Mirror Aluminum Coils?

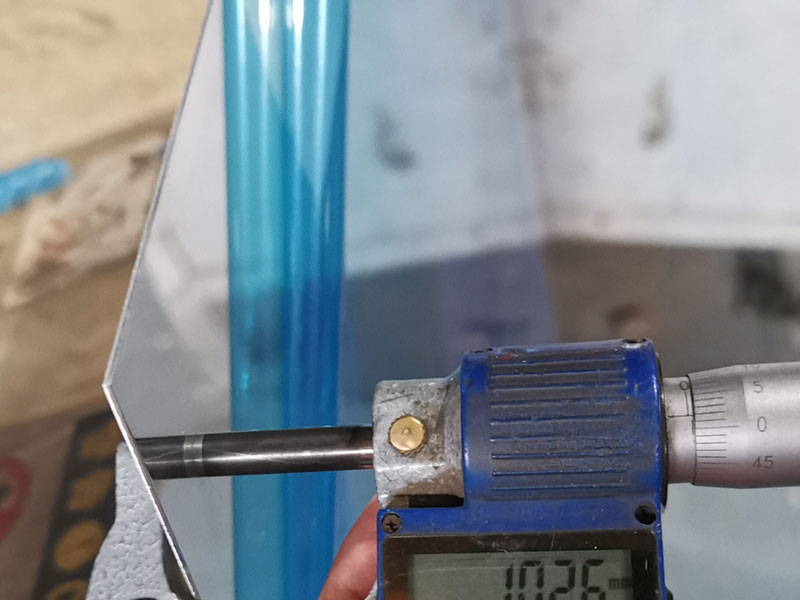

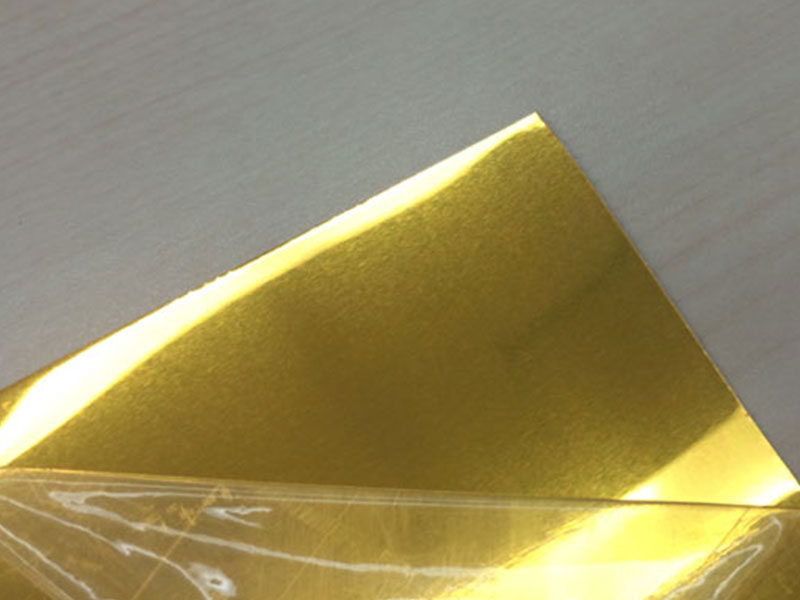

Anodized mirror aluminum coils are produced through a sophisticated anodizing process that enhances both durability and aesthetic appeal. This method not only provides an attractive mirrored finish but also protects the aluminum, ensuring a longer life span while resisting corrosion and wear.

Why Choose 1050 and 1060 Aluminum Grades?

Two of the most popular types of anodized aluminum coils are the 1050 and 1060 series, and for good reasons:

-

1050 Aluminum Grade: Known for its exceptional corrosion resistance and conductivity, the 1050 aluminum grade is ideal for environments requiring enhanced durability without significant weight. This makes it perfect for applications such as signage and decorative elements where aesthetically pleasing surfaces are a must.

-

1060 Aluminum Grade: The 1060 grade offers similar features to the 1050 but with a slightly higher strength. This grade is particularly beneficial in constructions that require a mixture of durability and flexibility. The stunning mirror finish provides an eye-catching effect that amplifies visual appeal in architecture and interior designs.

Advantages of Using Anodized Mirror Aluminum Coils

-

Aesthetic Appeal: The unique mirror-like finish ensures that anodized aluminum coils will stand out in any application, giving structures a modern feel while reflecting the surrounding environment.

-

Durability: The anodizing process considerably increases the surface hardness. By providing a protective oxide layer, it safeguards against scratches and dents, making it an ideal choice for outdoor elements that are constantly exposed to the elements.

-

Low Maintenance: Anodized aluminum is easy to clean and requires minimal maintenance, saving time and costs for businesses. The finish typically resists dirt accumulation and offers a longer-lasting sheen without frequent polishing.

-

Eco-Friendly Option: Anodized aluminum coils are recyclable, making them an environmentally friendly choice. They can be reused without losing their structural integrity or appearance, contributing to sustainable building practices.

Applications of Anodized Mirror Aluminum Coils

The versatile nature of anodized mirror aluminum coils allows them to be used in various industries, including:

-

Architecture and Construction: Building facades, ceilings, and siding frequently use anodized mirror aluminum due to its lightweight and reflective properties.

-

Automotive Components: Interior trimming and exterior panels benefit from the mirrored aesthetic, combining functionality with sophisticated design.

-

Consumer Products: From appliances to furniture, the shiny finish and bonus durability make it a preferred choice for consumer goods that need a modern touch.

https://www.aluminumplate.net/a/anodized-mirror-aluminum-coils-1050-1060.html