2 mm black anodised aluminium sheet

In the realm of materials engineering and industrial design, the 2 mm black anodised aluminium sheet is a testament to both innovation and utility. Beyond its sleek, modern aesthetic, this alloy sheet embodies a fusion of technical prowess and practical functionality that empowers numerous industries.

At its core, the 2 mm black anodised aluminium sheet refers to an aluminium substrate with a nominal thickness of 2 millimeters finished through an anodisation process that enriches its surface, imparting a deep black hue. This treatment involves electrochemical passivation processes which create a robust oxide layer on the aluminium surface, ensuring enhanced durability, corrosion resistance, and aesthetic appeal.

Parameters & Material Composition

Typically sourced from Aluminium Alloy 3003 or 5005 series, this sheet balances formability with strength, crucial for precise industrial applications.

| Parameter | Specification |

|---|---|

| Alloy | 3003-H14 / 5005-H34 (common alloys) |

| Thickness | 2.00 ± 0.05 mm |

| Surface Finish | Black anodised (Type II or Type III anodising) |

| Tensile Strength | 120 - 165 MPa (varies with tempering) |

| Yield Strength | ~80-110 MPa |

| Density | 2.70 g/cm³ |

| Melting Point | Approximately 660 °C |

The hardened anodic oxide layer often ranges between 10 to 25 microns in thickness and greatly improves surface hardness—often exceeding 200 HV (Vickers Hardness)—without effectuating alterations to the sheet’s underlying flexibility and lightweight nature.

Alloy Tempering and Production Conditions

The tempering status commonly associated with these sheets is H14 to H34, recognizing the half-hard condition resulting from strain hardening after cold rolling. This status achieves a balanced metallurgical characteristic of moderate strength coupled with significant ductility, allowing the sheet to be bent, formed, or fabricated without compromising structural integrity.

Anodising adheres to implementation standards such as MIL-A-8625 Type II (sulfuric acid anodizing) or Type III (hard anodizing). For black anodising, organic or inorganic black dyes penetrate the anodic layer and are sealed using hydrothermal treatments that stabilize the surface against fading or abrasion.

Functional Advantages from a Distinctive Viewpoint

What uniquely positions the 2 mm black anodised aluminium sheet at the forefront of material solutions is its engineered versatility rooted in well-balanced physical and chemical properties:

Working with 2mm black anodised aluminum sheet is a unique experience. The thickness itself is a sweet spot – substantial enough to be rigid and handle significant forming without cracking, yet thin enough for relatively easy fabrication and cost-effectiveness. The black anodization is where things get interesting. We often see inconsistencies in the dye penetration, particularly in deeper recesses or complex geometries. Achieving a perfectly uniform, matte black across a large sheet requires meticulous control of the anodizing process, and even then, minor variations are almost inevitable. Dealing with those slight imperfections, identifying their root causes (whether it's current density irregularities or inconsistent pre-treatment), and working with the QC team to meet our clients' increasingly demanding aesthetic standards is a daily challenge, but one I find incredibly rewarding.

Furthermore, the black anodization's impact on downstream processing is significant. It's harder to weld compared to the raw aluminum, and the anodize layer influences adhesive properties, requiring careful selection of bonding agents. This demands a deeper not only of the material properties, but also the entire production chain. The black finish, while visually striking, creates unique logistical hurdles – it's more susceptible to scratching and requires special handling during storage and transport. Ultimately, mastering the nuances of this material, from its limitations in manufacturing to optimizing its performance in the finished product, is what makes this job so engaging and technically satisfying.

Enhanced Corrosion and Weathering Resistance: The anodised layer acts as a hard ceramic barrier preventing aluminium oxidation — a crucial property for outdoor architectural applications or marine environments.

Electrical Insulation with Mechanical Reinforcement: Unlike bare aluminium, the anodic layer creates a dielectric barrier. This quality suits uses where electrical resistance combined with mechanical strength is paramount.

Thermal Management: The sheet delivers moderate thermal conductivity (~205 W/m•K) which finds utility in heat sinks or lightweight housing due to efficiency in heat dissipation without added weight.

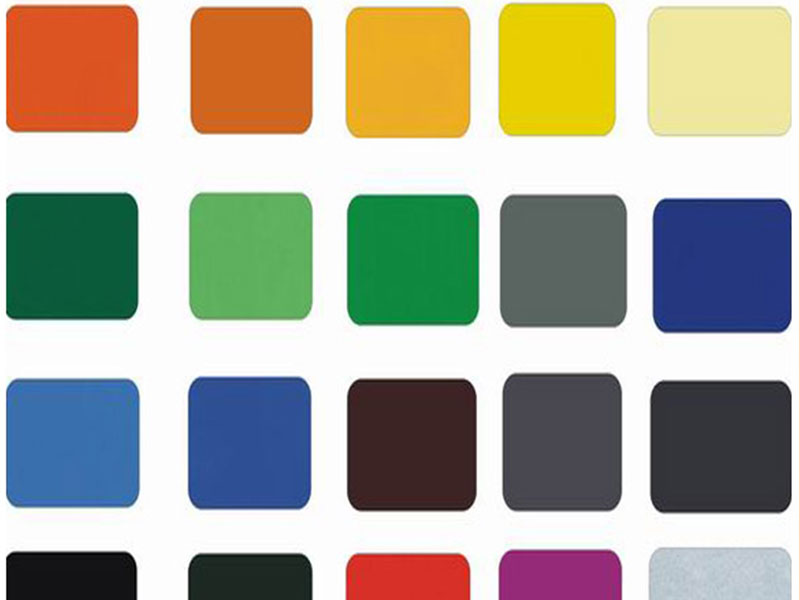

Surface Stability and Aesthetic Integrity: The black anodic film offers remarkable UV resistance — rare among pigmentation techniques — resulting in color fastness for mobile devices, instrumentation panels, or decorative facades.

Diverse Industrial Applications & Innovative Implementations

Given its functional toppings, the 2 mm black anodised aluminium sheet finds natural synergy across a broad spectrum of sectors, depicted in examples where technical demands meet intelligent material selection:

Architectural Cladding and Façade Systems: The corrosion resistance and modern black finish complement contemporary architectural themes while safeguarding urban installations from industrial pollutants and weather extremes.

Electronics & Instrument Panels: Combination of electrical insulance and superior thermal properties assures reliable casing solutions that prevent device overheating and electrical shocks.

Aerospace Components: Power-to-weight advantage derived from choosing aluminium that meets stringent aerospace standards results in durable, lightweight parts like interior trims and control surfaces.

Automotive Trim and Interior Decorative Elements: Stylized surfaces resistant to abrasion endure the challenging lemon-squeezy environments found inside daily vehicles.

Solar Panel Frames: Longevity specified in black anodisation and resistance properties strengthens photovoltaic hulks against oxidation and elemental damage.

Chemical Composition Table: Alloy 3003 Typical Range (wt%)

| Element | Composition (%) |

|---|---|

| Aluminium (Al) | Balance (approximately 97%) |

| Manganese (Mn) | 1.0% - 1.5% |

| Copper (Cu) | 0.05% - 0.20% |

| Iron (Fe) | Up to 0.7% |

| Silicon (Si) | Up to 0.6% |

| Zinc (Zn) | Up to 0.10% |

| Others | Trace |

https://www.aluminumplate.net/a/2-mm-black-anodised-aluminium-sheet.html