Embossed aluminum sheet 1100 1060 3003 5052

Embossed aluminum sheets have become integral materials across multiple industries due to their lightweight nature, corrosion resistance, aesthetic appeal, and enhanced surface performance. Among the numerous grades available, the alloy variants 1100, 1060, 3003, and 5052 is know as the most widely utilized.

What is Embossed Aluminum Sheet?

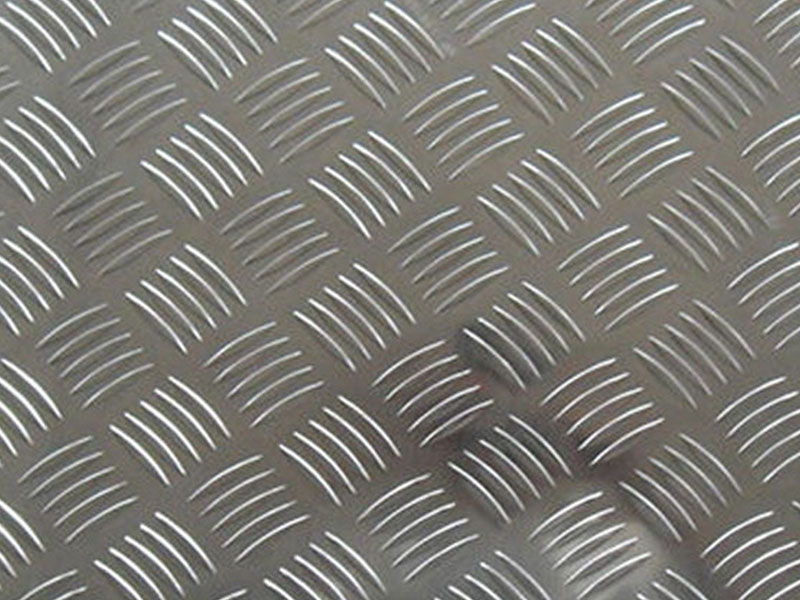

Embossed aluminum sheets refer to aluminum sheets that have been cold-rolled and then passed through embossing rollers to create textured or raised patterns on the surface. This surface texturing improves not only the non-slip properties but also the decorative aesthetics and mechanical gripping of the sheet.

Working with embossed aluminum sheets in 1100, 1060, 3003, and 5052 alloys for stucco applications reveals distinct performance characteristics. 1100 and 1060, being commercially pure aluminum, offer excellent formability and embossing consistency, resulting in a clean, crisp stucco pattern. However, their relatively low strength can lead to issues with handling and potential damage during processing or shipping, especially with deeper embossments. We've found that 3003, a manganese-strengthened alloy, provides a good balance between formability and strength, minimizing these handling issues. It also tends to hold the embossing detail exceptionally well, offering a superior stucco finish. The choice between these alloys often comes down to balancing the desired aesthetic finish against the practical demands of manufacturing and final product durability.

The 5052 alloy, a magnesium-aluminum alloy, presents a different set of considerations. While its higher strength and corrosion resistance are attractive, its slightly reduced formability necessitates more careful control during the embossing process. We've observed that excessively deep or complex stucco patterns can be challenging to achieve with 5052 without risking cracking or tearing. Therefore, its use in stucco embossed aluminum sheet is often limited to applications demanding superior strength and outdoor longevity, possibly with simpler, shallower embossing patterns. Ultimately, material selection for our stucco embossed aluminum sheets involves careful

The embossing, when combined with high-quality aluminum alloy bases, brings superior corrosion resistance, strength, workability, and thermal performance when compared to traditional flat aluminum sheets.

Common Alloy Series: 1100, 1060, 3003, and 5052

1. Alloy 1100:

- Purity: ~99.0% Aluminum

- Chemical Composition Highlights: Very low impurities, minimal silicon, iron.

- Temper Available: H14, H24, etc.

- Features: Excellent corrosion resistance, very good thermal/electrical conductivity, soft and highly workable, moderate strength.

2. Alloy 1060:

- Purity: ≥99.6% Aluminum

- Details similar to 1100, slightly more aluminum content.

- Exceptionally high corrosion resistance and softness.

3. Alloy 3003:

- Composition expanded to include ~1.2% manganese (Mn).

- Tempered in O and H14 states predominantly.

- Adds excellent mechanical strength while maintaining good corrosion resistance and workability.

4. Alloy 5052:

- Composition includes ~2.5% magnesium leading to significant strength boost.

- Better resistance to marine environments, higher fatigue resistance.

- Usually temper variants like H32.

Mechanical and Chemical Parameters

| Parameter | 1100 | 1060 | 3003 | 5052 |

|---|---|---|---|---|

| Aluminum Content (%) | min 99.0 | min 99.6 | min 97.0 | min 97.25 |

| Silicon (Si) (%) | 0.20 max | 0.25 max | 0.60 max | 0.40 max |

| Iron (Fe) (%) | 0.95 max | 0.35 max | 0.70 max | 0.40 max |

| Manganese (Mn) (%) | 0.05 max | 0.05 max | 1.0–1.5 | 0.10 max |

| Magnesium (Mg) (%) | 0.05 max | 0.03 max | 0.10 max | 2.2–2.8 |

| Tensile Strength (MPa) | ~70–110 | ~35–45 | 130–180 | 210–260 |

| Yield Strength (MPa) | ~40–70 | ~25–35 | 60–120 | 150–220 |

| Elongation (%) | 25-45 | 35-50 | 12-34 | 10–18 |

Values depend on temper condition.

Temper Designations and Their Effects

- O (Annealed): Softest temper; useful for forming.

- H12, H14, H22, H24, etc. (Strain hardened tempers): Increasing strength and hardness but less formable.

- H32: Specifically for 5052, offering medium strength and good ductility.

The temper significantly affects the mechanical strength and workability. Embossing typically happens after tempering or during cold-roll reductions to ensure stable embossing without cracking.

Standards and Quality Implementation

Typically, manufacturing of embossed aluminum sheets conforms with:

- ASTM B209 (Specification for Aluminum and Aluminum-Alloy Sheet and Plate)

- EN 485-2 (Aluminium and aluminium alloys — Sheet, strip, and plate — Part 2: Mechanical properties)

- GB 3880 (China aluminum alloy standards)

- JIS H4000 (Japanese Standards)

Embossed sheets additionally undergo strict quality inspections comprising:

- Pattern depth & uniformity checks

- Sheet thickness precision via die gap controls

- Corrosion resistance testing in salt spray chambers when necessary

Functions and Applications

Anti-slip & Safety Surfaces:Embossed patterns greatly enhance grip making them ideal for floorings in factories, staircases, and transport containers.

Decorative Usage:The unique texture with polished or hitter aesthetics is sought by interiors & vehicle industries for panels and facades.

Thermal and Acoustic Performance:Variants like 5052 offer good thermal reflectivity; surfaces can support better sound insulation membranes.

Corrosion Resistance:Over years, 5052 embossed sheets are being embraced by marine and offshore applications fighting harsh climatic degradation risks.

Packaging and Roofing:Lightweight advantages with reinforced grinding on embossed plates help in roofing and packaging industries by improving rigidity without weight tradeoffs.

Why Choose Different Aluminum Alloys?

- 1100 & 1060: Prioritize formability for shaping crafts or symbolic aluminum arts.

- 3003: Employed where superior strength without complex heat treatment involved;good for roofing, siding, and duct work.

- 5052: Use when fatigue strength, corrosion durability equal priority, like vehicle bodies, boats, and petrochemical.

https://www.aluminumplate.net/a/embossed-aluminum-sheet-1100-1060-3003-5052.html