1100 H12 mirror finish aluminium sheets

In the adaptable landscape of construction and design materials, mirror finish aluminum sheets is know not only for their functionality but also for their aesthetic appeal. Among the metals, 1100 H12 mirror finish aluminum sheets have carved a distinctive niche, owing to their unique properties and myriad applications.

1100 H12 Aluminum: A Definition

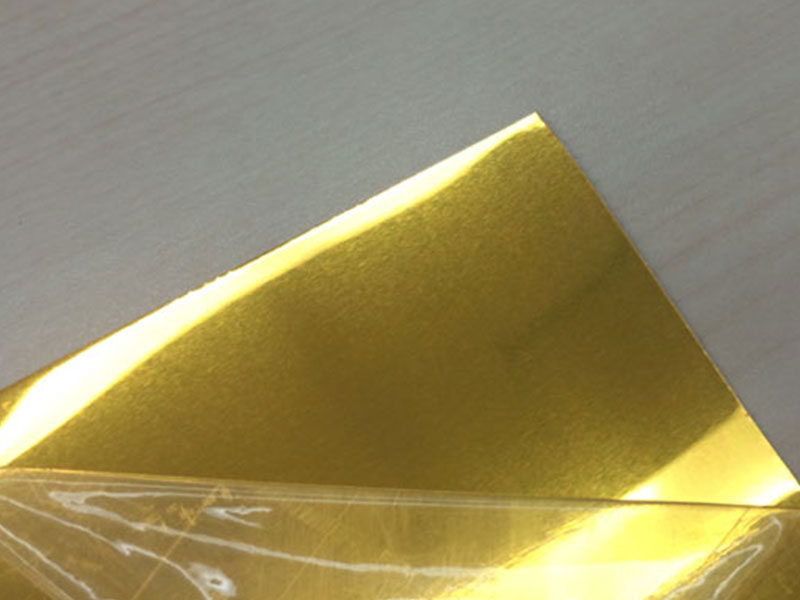

Before diving into mirror finishes, it’s fundamental to grasp what constitutes 1100 H12 aluminum. As a member of the aluminum 1000 series, 1100 aluminum is notable for its high corrosion resistance, thermal conductivity, and malleability. The letter “H12” signifies a partially hardened state, emphasizing its workability without compromising structural integrity. When brushing it to a mirrored surface, the sheet transforms into a product that resonates with innovation.

Working with 1100 H12 mirror finish aluminum sheets presents a unique set of challenges and rewards. The incredibly high reflectivity demands meticulous handling – even fingerprints can mar the surface, requiring constant vigilance during processing and packaging. We've had to develop specialized techniques, from using cleanroom gloves to employing specialized polishing compounds and automated handling systems, to maintain the consistent, pristine finish our clients demand. The material's softness, a consequence of its high purity, means it's susceptible to scratching and deformation, forcing us to adjust our machinery and workflows accordingly. Seeing a perfectly polished sheet reflect the entire factory is always a rewarding moment, a testament to the precision and care involved in its production.

Beyond the technical hurdles, there's a certain artistry to achieving that mirror-like finish. It’s not simply a matter of mechanical processes; it requires an of the interplay between different polishing stages, the correct application of abrasives, and even the ambient temperature and humidity. Experienced technicians can almost instinctively feel the right pressure and know when a sheet is approaching its optimal reflection. We are constantly experimenting with minor tweaks to our processes, searching for that elusive "perfect" reflection, even though the standards are already exceedingly high. This ongoing quest for perfection, combined with the sheer beauty of the final product, makes working with 1100 H12 sheets both demanding and deeply satisfying.

The Distinction of the Mirror Finish

The process of achieving a mirror finish on aluminum is intricate, transforming a regular metal sheet into a spectacle of reflecting light and color. Achieving this lustrous appearance involves precise polishing or chemical treatment techniques that not only enhance aesthetic appeal but also amplify surface protection through enhanced oxidation resistance. The result? Unmatched optics that evoke imagination—ideal for various industries.

Advantages Only 1100 H12 Can Provide

-

Lightweight yet Tough: The 1100 H12 mirrors possess remarkable toughness while remaining lightweight. This intrinsic characteristic makes transporting and handling practical even for large applications, setting it apart when direct usage arises in reflections, artworks, and displays.

-

Superior Reflective Quality: The mirror finish provides over 85% reflectivity, making 1100 H12 sheets suitable for architectural applications and lighting design. Imagine decorative panels or backsplashes that do not just serve functions but create a stunning ambiance and add an artistic statement through reflection.

-

Formability Crafts: The considerable ductility of 1100 H12 allows it to accomplish complex shapes without undue strain. Thus, businesses in automotive and aerospace can create sophisticated designs requiring naturally reflective surfaces that withstand harsh conditions.

Where Innovation Fulfills Beauty: Your Uses Await

Architecture and Interior Design

The ascendant place of mirrors in contemporary architectural designs cannot be underrated. Interior designers leverage the allure of 1100 H12 mirror finish aluminum sheets to enhance open spaces and create inevitable light reflection. It is common to see these sheets nowadays incorporated in dynamic facades, elevator interiors, and wall coverings, generating fluid interaction between space and light.

Artistic Endeavors

Given their malleable nature, 1100 H12 sheets are a preferred canvas for painters, sculptures, and installations—che affords a uniqueness that other mediums may lack. Artists prefer the smooth reflective surfaces to infuse their works with multidimensional views that react to their environment dramatically, cultivating a unique narrative through reflection.

Transportation and Automotive Applications

Today, efficiency and weight reduction head automotive innovation. The lightweight property of 1100 H12 merely aligns with the industry's imminent standards, facilitating productions that count each gram endured by sleek designs navigating both aesthetics and efficiency.

https://www.aluminumplate.net/a/1100-h12-mirror-finish-aluminium-sheets.html