Aluminum sheet for wine cap

In the world of fine wines, every detail counts—from the vineyard to the bottle cap. An often overlooked yet critical component is the aluminum closure sheet used for wine caps. This material not only protects the wine during transport and storage but also enhances aesthetic appeal and ensures product integrity.

Why Aluminum Closure Sheets Are Ideal for Wine Caps

Aluminum’s unique combination of light weight, corrosion resistance, malleability, and recyclability offers unmatched advantages in the production of wine closures, outperforming traditional corks and plastics in various contexts.

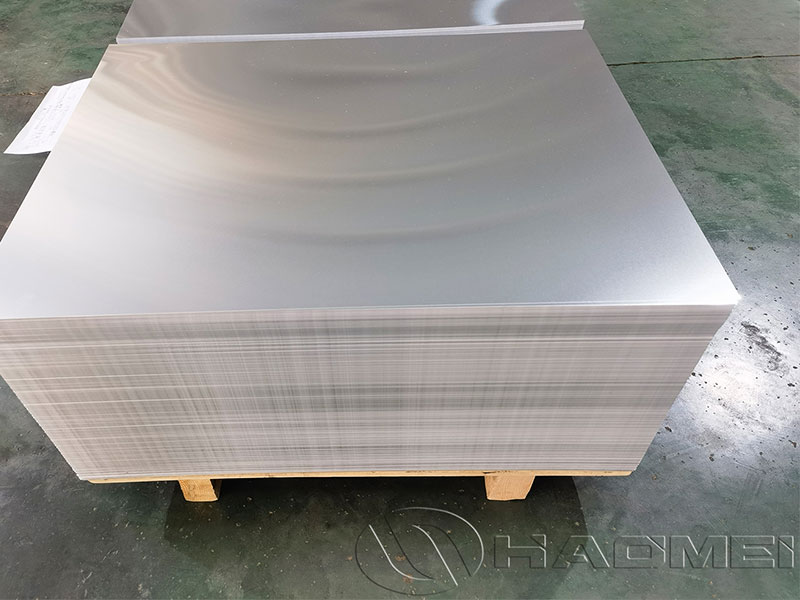

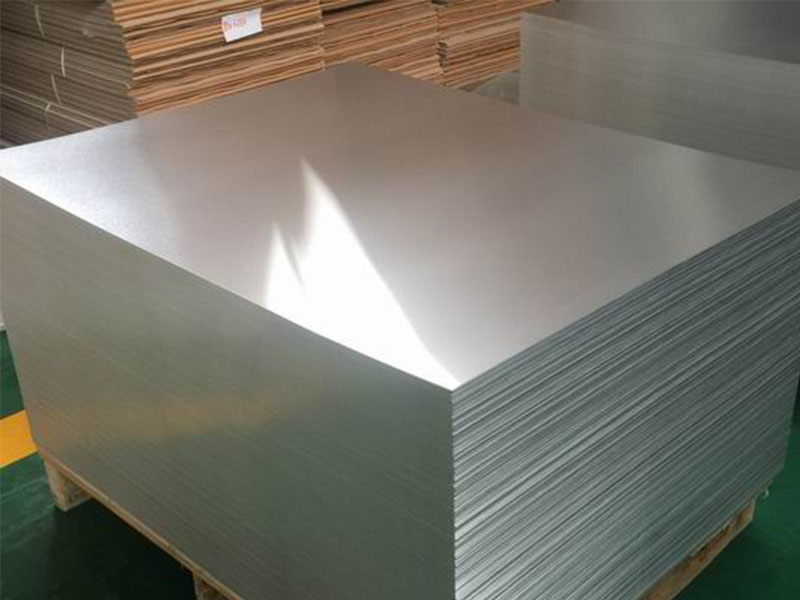

The aluminum we use for wine cap production is a fascinating material. We're not just dealing with any sheet; it's a highly specified alloy, carefully chosen for its formability, corrosion resistance, and ability to accept printing and lacquering. I've seen firsthand how tiny variations in the temper of the aluminum can significantly impact the ease of drawing the caps into their final shape. A slightly harder sheet might lead to more cracking during the process, resulting in scrap and lost production time. Conversely, a softer sheet might dent too easily during handling and shipping, impacting the aesthetic appeal and potentially the integrity of the seal. Finding that "Goldilocks" zone of material properties is a constant challenge and a significant source of pride when we nail it.

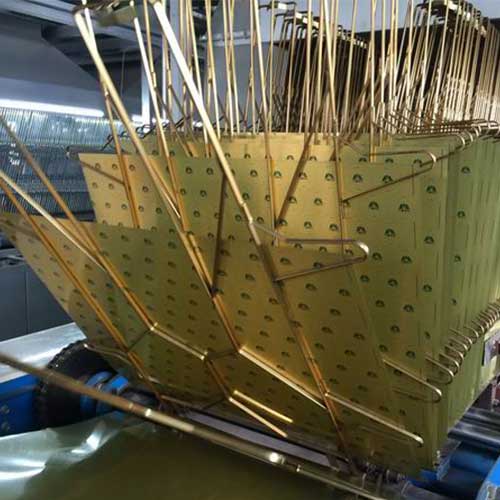

Beyond the material itself, the process of transforming the flat sheet into a functional wine cap is a marvel of engineering. We utilize high-speed presses and highly specialized tooling, each component crucial in achieving the precise dimensions and consistent quality demanded by our clients. I've spent countless hours troubleshooting minor inconsistencies in the final product – a slightly uneven edge, a subtle imperfection in the print – and each instance has deepened my of the intricate interplay between material science, manufacturing processes, and quality control. It's incredibly rewarding to see our perfectly formed aluminum caps, ready to protect and preserve the fine wines they crown.

Barrier Properties & Corrosion ResistanceAluminum creates an excellent barrier to external contaminants such as oxygen, moisture, and UV light — all factors that accelerate wine spoilage. Its inherent corrosion resistance safeguards against oxidation that can deteriorate both the cap and the wine, preserving flavor profiles from fermentation through aging.

Material Attribution: Alloy Choice & TemperingThe appropriate alloy selection is crucial. Most wine closure sheets utilize 8011 or 3105 aluminum alloys due to their optimal balance of strength, formability, and surface finish.

- Alloy 8011 H19 or H24: Provides higher strength via strain hardening and moderate hardness needed to withstand clamping during closure application.

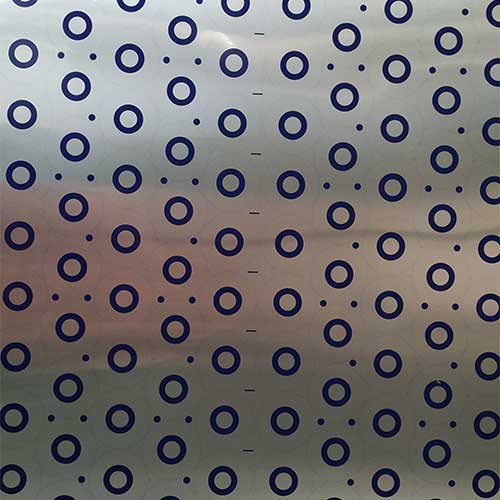

- Alloy 3105 H14 or H24: Offers better corrosion resistance and is easily tempered for superb formability, allowing intricate designs on caps.

The temper designation (e.g., H19, H24) describes the mechanical and thermal treatments performed post-manufacture. “H19” implies strain-hardened to a full hard condition with minimal ductility, preventing deformation during capping processes. Meanwhile, “H24” is strain-hardened and partially annealed for increased flexibility without compromising integrity.

- Manufacturing Standards & ComplianceAdherence to international standards ensures consistent quality and safety:

- ASTM B209: Specifies aluminum sheet and plate alloy chemical and mechanical properties.

- ISO 16117: Governs the purity and dimensional tolerances of aluminum closure materials for beverages.

- FDA Approval: For food-contact safety certifications.

Parameters of Aluminum Closure Sheets for Wine Caps

| Parameter | Typical Range/Value | Description |

|---|---|---|

| Thickness | 0.12 - 0.23 mm | Optimal gauge to balance strength and flexibility |

| Alloy | 8011, 3105 | Common for food-grade consumable closures |

| Temper | H19, H24 | Defined for formability and rigidity |

| Width | 1000 - 1250 mm | Standard coil/form sizes |

| Weight | ~2.7 g/cm³ | Aluminum’s density (for material calculation) |

| Surface Finish | Chrome plated / epoxy coating | Increases corrosion resistance and printability |

Chemical Composition of Typical Aluminum Alloys for Wine Caps

| Alloy | Al (%) | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Ti (%) |

|---|---|---|---|---|---|---|---|---|

| 8011 | 95.00+ | 0.8 max | 1.0 max | 0.10 max | 0.30 max | 0.15 max | 0.10 max | 0.03 max |

| 3105 | 98.0 min | 0.25 max | 0.40 max | 0.05 max | 0.10 max | 0.60 - 1.0 | 0.10 max | 0.03 max |

Implementation & Application

During production, aluminum closure sheets are precision-rolled and often coated or laminated with UV-resistant, food-safe lacquers to improve aesthetics and longevity without contaminating the wine.When applied in bottling plants, these sheets are cut and drawn into cap shells matching the thread patterns designed for wine bottles. The temper level of the aluminum directly affects sealing performance, whereby closures must flex slightly for hermetic sealing without cracking or deformation.

Environmental Benefits

Being 100% recyclable, aluminum closure sheets minimize wine packaging environmental impact, enabling brands to appeal to eco-conscious consumers without sacrificing quality or performance.

https://www.aluminumplate.net/a/aluminum-sheet-for-wine-cap.html