Color coated prepainted mirror finish aluminum coil

Color coated prepainted mirror finish aluminum coil is a high-performance aluminum product designed to deliver appealing aesthetics, superior durability, and excellent functionality. It combines a reflective mirror finish with a color-coated prepainted layer, making it ideally suited for a wide range of industrial and architectural applications.

Features

| Feature | Description |

|---|---|

| Mirror Finish Surface | Offers a smooth, highly reflective surface with a chromium-free process, enhancing visual appeal and enabling effective light reflection. |

| Color Coated Layer | Durable PE/PVDF coatings provide rich and vibrant colors along with strong resistance to UV radiation and weathering. |

| Corrosion Resistance | Protective coatings improve resistance against oxidation and corrosion, especially in harsh environments. |

| Lightweight & Strong | Combines the lightweight nature of aluminum with adequate mechanical strength suitable for various structural uses. |

| Excellent Formability | Good bending, cutting, and molding capabilities to fit complex fabrication processes. |

| Environmentally Friendly | Fully recyclable materials with no heavy metals used in coating ensuring sustainability. |

Chemical Composition

The aluminum coil used typically meets the alloy composition requirements detailed in the following table. This ensures optimum balance between flexibility, strength, and surface finish quality.

| Element | Typical Content (%) | Remarks |

|---|---|---|

| Al | Balance | Main element, purity requirement |

| Si | 0.1 – 0.5 | Improves strength & electrical conductivity |

| Fe | 0.2 max | Limits inclusions for better surface quality |

| Cu | 0.1 max | Controlled to prevent corrosion issues |

| Mn | 0.1 max | Enhances mechanical properties |

| Mg | 0.1 max | Used for strengthening |

| Zn | 0.1 max | Typically kept low to enhance corrosion resistance |

| Ti | 0.05 max | Grain refiner for improved texture |

Technical Specifications

The product specifications below define the typical mechanical and physical parameters ensuring high-quality performance of the color coated mirror finish coil.

| Parameter | Unit | Typical Values | Remarks |

|---|---|---|---|

| Alloy Grade | - | 1100 / 3003 | Common alloys for mirror finish application |

| Tempers | - | H14 / H18 | Ranging from half-hard to hard tempers |

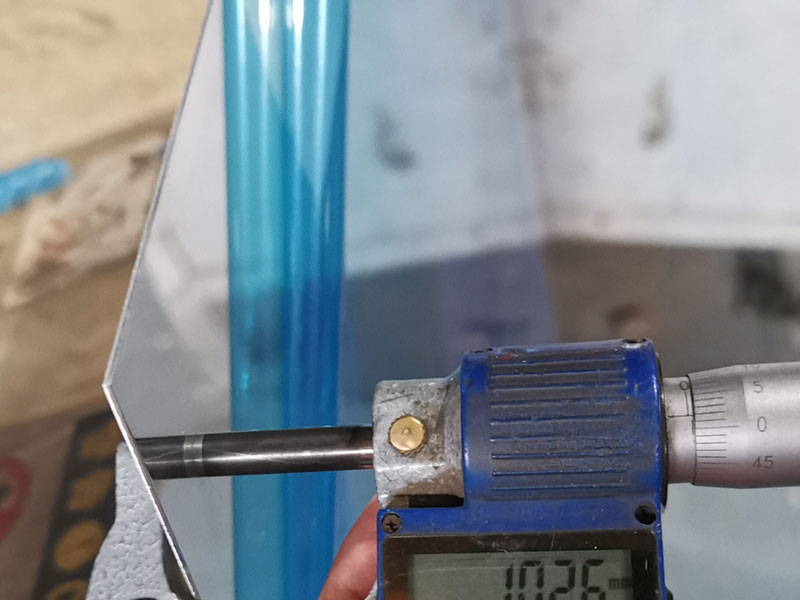

| Coil Thickness | mm | 0.3 - 2.0 | Depending on customer requirement |

| Coil Width | mm | 1000 – 1600 | Standard industry sizes |

| Surface Finish | - | Mirror finish & color coated | Mirror bright with color coatings (PE/PVDF) |

| Tensile Strength | MPa | 90 – 140 | Varies by alloy and temper |

| Yield Strength | MPa | 50 – 110 | Mechanical resistance ensuring durability |

| Elongation | % | 10 – 30 | Ductility allowing formability |

| Coating Thickness (Top) | µm (microns) | 15 – 25 | Measured on outer surface |

| Coating Thickness (Back) | µm (microns) | 5 – 10 | Supports corrosion protection |

| Reflectivity | % | 80 – 90 | Mirror finish providing superior light reflection |

Performance Benefits

- Superior Aesthetics: Mirror finish aluminum provides a clean, sleek, eye-catching appearance perfect for architectural use in interior and exterior applications.

- Durability: Color coatings resist fading, chalking, and peeling from exposure to sun, rain, and pollutants, thus extending the product lifecycle.

- Corrosion Protection: Enhances longevity even in coastal or industrial environments where corrosion typically limits aluminum use.

- Formable & Lightweight: Allows ease of processing without damage to the coating or finish, reducing transportation and handling costs.

- Energy Reflectivity: Mirror finish effectively reflects heat and light, supporting applications in solar energy systems or heat-insulating designs.

- Custom Color Options: RAL and other color standards allow integration tailored to design needs.

Applications

Color Coated Prepainted Mirror Finish Aluminum Coil's combination of durability, aesthetics, and technical performance makes it an excellent choice for the following industries:

| Industry | Application | Notes |

|---|---|---|

| Architectural & Interior | Curtain walls, ceiling panels, wall decor, elevator cladding | Enhances mergers of functionality and style assertion |

| Signage & Display | Reflective signage, advertising boards | Durable in weather and highly visible |

| Transportation | Automotive trims, metro lining, aircraft cabin panels | Combines light weight with corrosion resistance |

| Solar Energy | Reflective elements in solar concentrators | Improves system efficiency |

| Consumer Goods | Appliance covers, electronic cases | Adds aesthetic and protective element |

| Furniture | Metal furnishings that require visual appeal | Durable finish and scratch resistance |

Color coated prepainted mirror finish aluminum coil blends advanced coating technology with refined surface treatment revealing a perfect balance of aesthetics and functional durability. Its rust resistant, UV stable coatings on a visually high-reflective aluminum substrate provide distinct advantages across multiple industrial applications from architecture to transportation. Thanks to its combination of light weight, strength, and environmental sustainability, this product stands out as a versatile and long-lasting option in the modern aluminum products range.

For specific customizations, alloy grades, or application-specific questions, please contact our technical support team.

https://www.aluminumplate.net/a/color-coated-prepainted-mirror-finish-aluminum-coil.html