5182 H111 Reflective Mirror Glass Aluminum

Aluminum is at the forefront of modern manufacturing, renowned for its lightweight properties, durability, and flexibility when used in various applications. Among its many types, 5182 H111 Reflective Mirror Glass Aluminum stands out for its remarkable reflective qualities and mechanical characteristics.

What is 5182 H111 Reflective Mirror Glass Aluminum?

The 5182 alloy belongs to the aluminum-magnesium series, recognized for embedding strong corrosion resistance and good weldability profiles. The H111 temper indicates a partially annealed condition, ensuring the aluminum possesses some degree of softening while still retaining strength. This alloy’s addition of magnesium strengthens the material, making it versatile for formability and enriched with luminescent reflective attributes when polished.

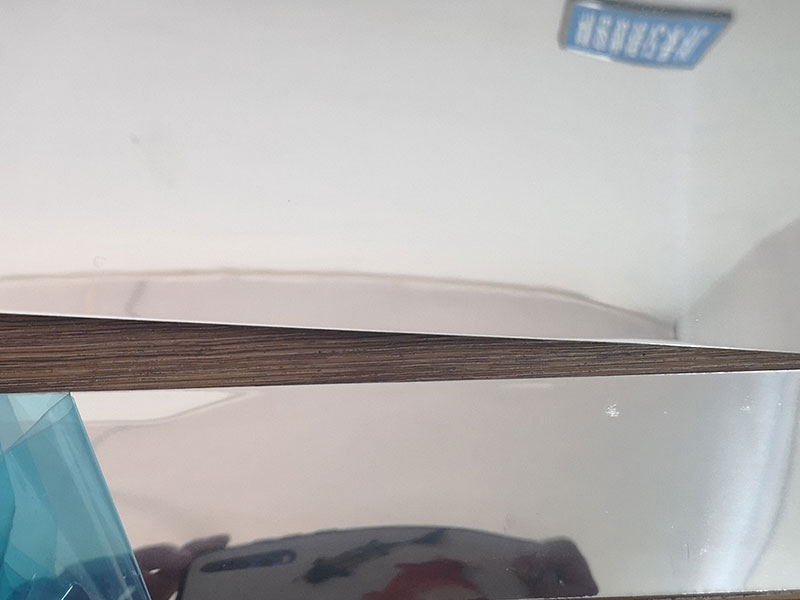

Working with 5182 H111 Reflective Mirror Glass Aluminum, I've come to appreciate its unique properties beyond its straightforward application as a mirror. The 5182 alloy itself contributes excellent formability, which is crucial for achieving the complex shapes we sometimes need for specific customer orders. The H111 temper provides a good balance between strength and ductility; it’s tough enough to withstand the rigors of fabrication yet malleable enough to avoid cracking or tearing during bending or stamping. This balance is particularly noticeable when working with larger sheets. We frequently fine-tune the polishing process to maximize the reflectivity, and I've found that even subtle variations in pressure or abrasive type can significantly impact the final quality, especially at the edges. Getting a uniformly reflective surface across the entire sheet requires a delicate touch and precise control.

Furthermore, the material's susceptibility to surface imperfections adds a layer of complexity. Scratches, even minor ones, are highly visible due to the reflective nature. This means meticulous handling throughout the entire production process – from storage and transport to the polishing and packaging stages – is critical. We've implemented several quality control checks, and I've been involved in developing a new training program for our team to minimize potential damage. the material's sensitivity to environmental factors, such as humidity and temperature fluctuations, is also to maintaining consistency in the final product. Ultimately, producing high-quality 5

Technical Details

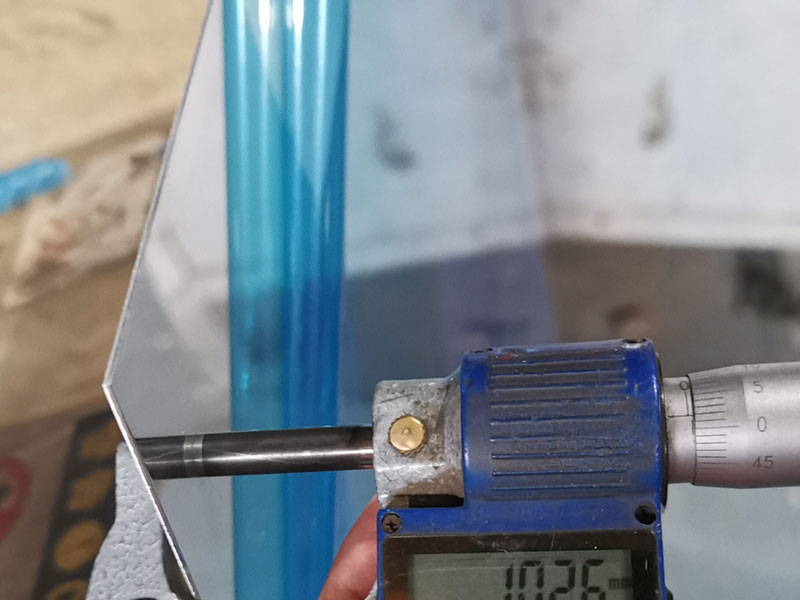

Below are the vital technical Specifications of 5182 H111 Reflective Mirror Glass Aluminum:

- Chemical Composition: Approximately 4.5-5.9% Magnesium and 0.4% Max copper.

- Yield Strength: Exceeds 230 MPa, providing excellent load-bearing capacity.

- Elongation After Fracture: Reaches over 15%, showcasing good workability during fabrication.

- Reflectivity: Capable of achieving 80% and above reflectivity, ensuring heightened visual appeal and efficiency.

These properties make it substantial in forming a mirror-like finish that reflects light intimately without high distortions.

Functions and Applications

Whether it’s utilized in architectural settings, manufacturing sectors, or consumer products, the popularity of 5182 H111 Reflective Mirror Glass Aluminum can most commonly be attributed to its multifunctional performance attributes.

1. Architectural Panels and Facades

The vibrant reflectivity of 5182 H111 makes it a superior choice for cladding in modern architectural designs. Not only does it enhance a building's aesthetics, but its durability against weather conditions fortifies the exterior while achieving a sleeker look.

2. Lighting and Decorative Use

This glaze-like attribute amplifies its use in production where high-quality aluminum reflection can optimize lighting. When utilized in LED fixtures or mirrored surfaces, it maximizes luminance and creates compelling visual presentations, perfect for showcases or decorative elements.

3. Automotive Components

In the automotive industry, 5182 H111 Reflective Mirror Glass Aluminum is seeing application in parts requiring aesthetic touch coupled with corrosion resistance. Light component manufacturing can contribute to lowering overall vehicle weight without compromising strength, directly aiding in fuel efficiency.

4. HVAC Applications

Air conditioning duct structures show improving performance reliability when crafted from this aluminum mirrors properties. Additionally, due to its low thermal conductivity, businesses replacing heavier metal duct systems are drawn toward this lightweight solution.

https://www.aluminumplate.net/a/5182-h111-reflective-mirror-glass-aluminum.html